Conventional tailings disposal involves storing slurry waste in surface ponds, which can pose environmental risks such as water contamination and land instability. Paste backfill, in contrast, uses a thickened mixture of tailings and binders to fill underground voids, enhancing mine stability and reducing surface waste footprint. This method improves resource recovery and supports sustainable mining practices by minimizing tailings exposure and promoting safer underground operations.

Table of Comparison

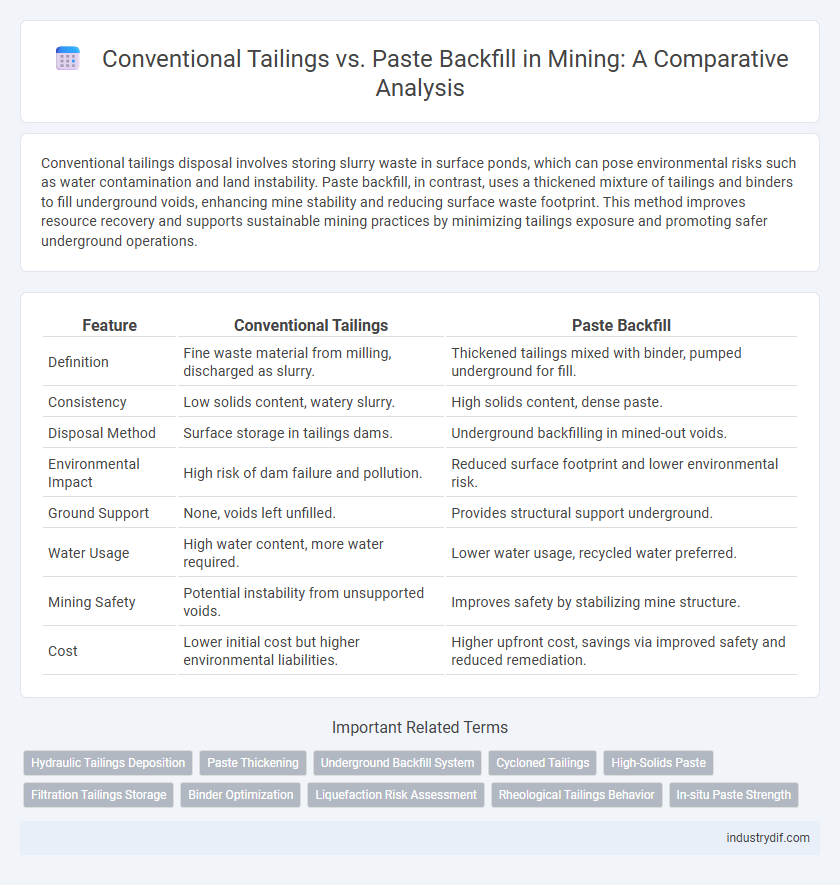

| Feature | Conventional Tailings | Paste Backfill |

|---|---|---|

| Definition | Fine waste material from milling, discharged as slurry. | Thickened tailings mixed with binder, pumped underground for fill. |

| Consistency | Low solids content, watery slurry. | High solids content, dense paste. |

| Disposal Method | Surface storage in tailings dams. | Underground backfilling in mined-out voids. |

| Environmental Impact | High risk of dam failure and pollution. | Reduced surface footprint and lower environmental risk. |

| Ground Support | None, voids left unfilled. | Provides structural support underground. |

| Water Usage | High water content, more water required. | Lower water usage, recycled water preferred. |

| Mining Safety | Potential instability from unsupported voids. | Improves safety by stabilizing mine structure. |

| Cost | Lower initial cost but higher environmental liabilities. | Higher upfront cost, savings via improved safety and reduced remediation. |

Introduction to Tailings Management in Mining

Conventional tailings management involves storing finely ground waste materials from ore processing in large surface dams, which can pose environmental risks such as dam failures and seepage. Paste backfill technology enhances tailings handling by mixing tailings with binders to create a thick, stable material that is pumped back into underground mine voids, reducing surface disposal footprints and improving ground stability. Effective tailings management strategies prioritize environmental protection, resource recovery, and operational safety in mining operations.

Overview of Conventional Tailings Systems

Conventional tailings systems involve the storage of finely ground mining waste in large, open tailings dams, posing significant environmental and safety risks such as dam failure and groundwater contamination. These systems typically require extensive land use and ongoing management to mitigate acid rock drainage and heavy metal leaching. Innovations in tailings management are driving the shift toward more sustainable methods like paste backfill, which improves stability and reduces environmental impact.

Fundamentals of Paste Backfill Technology

Paste backfill technology utilizes a mixture of tailings, water, and binders to create a dense, stable material for underground mine reinforcement, contrasting with conventional tailings disposal that stores waste on surface facilities. This method enhances ground control, reduces environmental impact by minimizing surface tailings dams, and improves resource recovery by allowing selective mining sequences. The core principle relies on optimizing paste rheology and strength development through binder types and curing conditions to ensure safe underground support.

Key Differences between Conventional Tailings and Paste Backfill

Conventional tailings are typically deposited as a slurry into tailings ponds, posing environmental risks such as seepage and dam failure, while paste backfill involves mixing tailings with binders to create a semi-solid material used to refill mined-out voids underground. Paste backfill enhances ground stability, reduces surface storage requirements, and minimizes environmental hazards by recycling tailings back into mine workings. Key differences include their physical state, environmental impact, and operational benefits, with paste backfill offering improved safety and sustainability in mining operations.

Environmental Impacts of Tailings Disposal Methods

Conventional tailings disposal often leads to significant environmental risks, including groundwater contamination and surface water pollution due to seepage and toxic runoff. Paste backfill reduces these impacts by immobilizing tailings within a chemically stable matrix, preventing leachate generation and minimizing land disturbance. Studies show paste backfill enhances mine site rehabilitation, lowers the risk of tailings dam failures, and promotes sustainable waste management practices.

Water Management and Recycling Efficiency

Conventional tailings disposal consumes significant volumes of water, often leading to challenges in water scarcity and environmental contamination. Paste backfill technology enhances water management by utilizing recycled process water mixed with fine tailings and binders, reducing freshwater demand and minimizing tailings storage footprints. This method significantly improves water recycling efficiency, promoting sustainable mining operations and reducing the water-related environmental impact.

Safety and Stability Considerations

Conventional tailings disposal often poses risks such as dam failures and environmental contamination due to its loose, water-saturated structure. Paste backfill, with its higher solids content and controlled placement, significantly enhances structural stability and reduces the likelihood of surface subsidence and dam breaches. Safety is improved through decreased water seepage and increased shear strength in paste backfill compared to conventional tailings storage, making it a more reliable option for mine waste management.

Cost Analysis and Economic Feasibility

Conventional tailings management incurs high costs due to extensive surface storage requirements, increased environmental compliance, and potential land reclamation expenses. Paste backfill offers economic advantages by reducing tailings disposal volume, enhancing underground mine stability, and enabling resource recovery that lowers overall operational costs. Cost analysis demonstrates that paste backfill's capital investment is offset by savings in waste management and improved mine productivity, making it a more economically feasible solution for sustainable mining operations.

Regulatory and Compliance Aspects

Conventional tailings disposal often faces stringent regulatory scrutiny due to risks of environmental contamination and groundwater pollution, mandating strict monitoring and containment measures. Paste backfill technology aligns with evolving compliance frameworks by enabling safer underground filling, reducing surface tailings storage, and minimizing environmental liabilities. Regulations increasingly favor paste backfill methods as they enhance waste management standards and support sustainable mining practices.

Future Trends in Tailings Handling Techniques

Future trends in tailings handling emphasize a shift from Conventional tailings disposal towards Paste backfill techniques due to enhanced environmental safety and resource recovery. Paste backfill utilizes thickened tailings mixed with binders, reducing surface storage footprints and minimizing groundwater contamination risks. Innovations in rheology control and binders are driving increased adoption of Paste backfill in underground mining operations to improve tailings stability and sustainable mine closure practices.

Related Important Terms

Hydraulic Tailings Deposition

Hydraulic tailings deposition involves transporting slurry through pipelines, where conventional tailings are typically stored in surface impoundments, posing environmental risks such as seepage and instability. Paste backfill, by contrast, offers improved water recovery and stability by combining tailings with binders to create a thixotropic material that can be pumped back underground for ground support, reducing surface storage footprint and mitigating environmental hazards.

Paste Thickening

Paste thickening enhances tailings management by producing high-density paste backfill with over 70% solids concentration, reducing water usage and improving underground mine stability compared to conventional tailings disposal. This method enables efficient water recycling, minimizes environmental footprint, and supports sustainable mining operations through controlled rheology and reduced surface storage requirements.

Underground Backfill System

Conventional tailings disposal involves storing slurry tailings in surface ponds, posing environmental risks and space constraints, whereas paste backfill utilizes dewatered tailings mixed with binders to create a thick, pumpable material for underground backfill, enhancing ground support and mine stability. Paste backfill systems improve resource recovery by enabling selective mining and reducing surface footprint, while conventional tailings disposal remains cost-effective but less sustainable for long-term underground backfill operations.

Cycloned Tailings

Cycloned tailings, produced through hydrocyclone separation, offer improved particle size distribution and reduced water content compared to conventional tailings, enhancing paste backfill stability and permeability. Utilizing cycloned tailings in paste backfill optimizes mine void filling, reduces surface tailings storage, and minimizes environmental impact in underground mining operations.

High-Solids Paste

High-solids paste backfill offers superior stability and reduced environmental impact compared to conventional tailings by minimizing water content and enhancing fill strength for underground mine support. Its higher solids concentration significantly reduces seepage and surface footprint, optimizing resource recovery and operational safety in mining operations.

Filtration Tailings Storage

Conventional tailings storage relies on slurry deposition in large impoundments that pose significant environmental risks such as dam failures and seepage, requiring extensive space and water management. Paste backfill utilizes filtered tailings with reduced moisture content, enabling safer underground backfill, minimizing surface storage footprint, and improving water recycling efficiency in mining operations.

Binder Optimization

Binder optimization in conventional tailings aims to balance cost and strength, often requiring higher cement content due to poor particle binding and water drainage; paste backfill, by contrast, utilizes optimized binder formulations with reduced cementitious materials, enhancing structural integrity while minimizing environmental impact and overall expenses. Advanced mix designs and mineral additives improve binder efficiency in paste backfill, resulting in superior compressive strength and reduced permeability compared to conventional tailings, promoting sustainable mining and tailings management.

Liquefaction Risk Assessment

Conventional tailings pose a higher liquefaction risk due to their loose structure and higher water content, increasing the potential for dam failure during seismic events. Paste backfill, with its higher solids concentration and cohesive properties, significantly reduces liquefaction susceptibility, enhancing mine stability and safety in tailings management.

Rheological Tailings Behavior

Conventional tailings exhibit lower yield stress and viscosity, leading to easier pumpability but increased risk of segregation and water seepage, whereas paste backfill demonstrates higher yield strength and thixotropic behavior, enabling improved stability and reduced environmental impact. Rheological properties of paste backfill, such as shear thinning and elasticity, are critical for ensuring effective pipeline transport and structural support in underground mining operations.

In-situ Paste Strength

Conventional tailings typically exhibit low in-situ strength, leading to higher risks of wall failure and reduced underground stability, whereas paste backfill demonstrates significantly improved in-situ strength due to its controlled cementitious properties, enabling enhanced ground support and minimized surface footprint. Paste backfill's superior consolidation and load-bearing capacity optimize underground mining safety and operational efficiency compared to traditional tailings disposal methods.

Conventional tailings vs Paste backfill Infographic

industrydif.com

industrydif.com