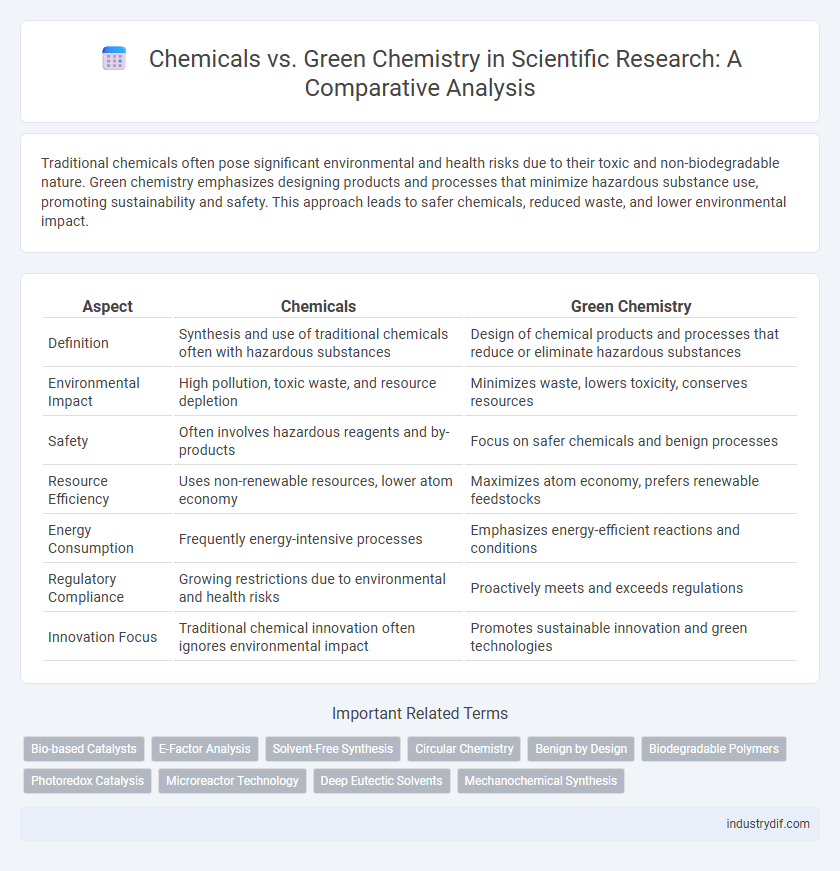

Traditional chemicals often pose significant environmental and health risks due to their toxic and non-biodegradable nature. Green chemistry emphasizes designing products and processes that minimize hazardous substance use, promoting sustainability and safety. This approach leads to safer chemicals, reduced waste, and lower environmental impact.

Table of Comparison

| Aspect | Chemicals | Green Chemistry |

|---|---|---|

| Definition | Synthesis and use of traditional chemicals often with hazardous substances | Design of chemical products and processes that reduce or eliminate hazardous substances |

| Environmental Impact | High pollution, toxic waste, and resource depletion | Minimizes waste, lowers toxicity, conserves resources |

| Safety | Often involves hazardous reagents and by-products | Focus on safer chemicals and benign processes |

| Resource Efficiency | Uses non-renewable resources, lower atom economy | Maximizes atom economy, prefers renewable feedstocks |

| Energy Consumption | Frequently energy-intensive processes | Emphasizes energy-efficient reactions and conditions |

| Regulatory Compliance | Growing restrictions due to environmental and health risks | Proactively meets and exceeds regulations |

| Innovation Focus | Traditional chemical innovation often ignores environmental impact | Promotes sustainable innovation and green technologies |

Introduction to Chemicals and Green Chemistry

Chemicals encompass a broad range of substances utilized in industrial, pharmaceutical, and agricultural applications, often associated with environmental pollution and health hazards due to their toxic and non-biodegradable nature. Green chemistry aims to design chemical products and processes that reduce or eliminate hazardous substances, emphasizing sustainability, renewable feedstocks, and energy efficiency. This field integrates principles such as atom economy and waste minimization to develop safer, eco-friendly alternatives while maintaining industrial effectiveness.

Historical Overview of Chemical Synthesis

Chemical synthesis has evolved significantly since the 19th century, marked by the rise of classical methods involving hazardous reagents and non-renewable resources. The development of green chemistry in the late 20th century introduced sustainable practices aimed at minimizing environmental impact, such as atom economy and safer solvent use. Historical milestones include the synthesis of urea by Friedrich Wohler, which challenged the vitalism theory, and later advancements emphasizing renewable feedstocks and waste reduction in synthesis design.

Key Principles of Green Chemistry

Green Chemistry emphasizes designing chemical products and processes that reduce or eliminate hazardous substances, guided by 12 key principles such as waste prevention, atom economy, and the use of safer solvents. These principles promote energy efficiency, renewable feedstocks, and the design of chemicals that degrade after use, minimizing environmental impact. Implementation of Green Chemistry leads to sustainable industrial practices that prioritize human and ecological health over conventional chemical approaches.

Environmental Impacts of Traditional Chemicals

Traditional chemicals often contribute to environmental pollution through the release of toxic substances, persistent organic pollutants, and hazardous waste that contaminate soil, air, and water ecosystems. Their production and disposal processes can generate greenhouse gases and bioaccumulative compounds, resulting in biodiversity loss and ecosystem disruption. Green chemistry aims to minimize these environmental impacts by developing safer, biodegradable, and non-toxic chemical alternatives that reduce waste and energy consumption.

Sustainable Alternatives in Chemical Manufacturing

Sustainable alternatives in chemical manufacturing emphasize the development of green chemistry techniques that reduce hazardous substances and minimize environmental impact. Innovations such as bio-based feedstocks, catalytic processes, and waste valorization replace traditional petrochemical methods, enhancing resource efficiency and toxicity reduction. These advancements align with regulatory frameworks and corporate sustainability goals, driving the transition towards safer, renewable, and economically viable chemical production.

Comparing Toxicity and Safety Profiles

Chemical substances traditionally used in industrial processes exhibit varying degrees of toxicity, often posing significant risks to human health and the environment through bioaccumulation and carcinogenic effects. Green chemistry principles prioritize the design of safer chemicals and sustainable processes that minimize hazardous emissions and reduce exposure to toxic substances. Comparative studies highlight that green chemistry formulations consistently demonstrate lower toxicity profiles and improved safety margins, contributing to safer occupational environments and reduced ecological impact.

Economic Considerations: Chemicals vs Green Chemistry

Economic considerations in chemicals versus green chemistry highlight significant cost differences, where traditional chemical processes often incur high expenses related to raw materials, energy consumption, waste management, and regulatory compliance. Green chemistry offers long-term economic benefits through reduced resource usage, minimized hazardous waste disposal costs, and enhanced process efficiency, driving sustainability and profitability. Investment in green technologies fosters innovation, risk reduction, and compliance with environmental regulations, which can lead to competitive advantages and market growth.

Regulatory Frameworks and Compliance

Regulatory frameworks governing chemicals emphasize risk assessment and hazard communication to ensure public safety and environmental protection. Green chemistry regulations prioritize the development and use of safer substances and processes, promoting sustainability through incentives and restrictions on hazardous materials. Compliance in both domains requires adherence to international standards such as REACH and TSCA, integrating innovation with strict environmental and health guidelines.

Innovations Driving Green Chemistry Adoption

Innovations driving green chemistry adoption include the development of bio-based solvents, catalytic processes that reduce waste, and energy-efficient synthetic routes. Advances in enzyme engineering have enabled selective reactions under mild conditions, minimizing hazardous byproducts. Continuous flow reactors and real-time monitoring systems further enhance process safety and sustainability in chemical manufacturing.

Future Trends in Chemical Science

Emerging future trends in chemical science emphasize the integration of green chemistry principles to minimize environmental impact and enhance sustainability. Innovations in catalysis, bio-based feedstocks, and waste valorization are driving the development of safer, energy-efficient chemical processes. Advancements in computational chemistry and machine learning accelerate the design of eco-friendly materials and predictive toxicology models, fostering a shift towards more responsible chemical production.

Related Important Terms

Bio-based Catalysts

Bio-based catalysts derived from renewable resources offer sustainable alternatives to conventional chemical catalysts, enhancing reaction efficiency while reducing environmental impact and toxicity. These catalysts promote green chemistry by enabling selective transformations under mild conditions, minimizing waste and energy consumption compared to traditional chemical processes.

E-Factor Analysis

E-Factor analysis quantifies the environmental impact of chemical processes by measuring the mass of waste generated per mass of product, where traditional chemical methods often exhibit higher E-Factors indicating greater waste production. Green chemistry aims to minimize E-Factor by optimizing reaction efficiency and incorporating safer, renewable solvents and reagents, resulting in more sustainable and eco-friendly processes.

Solvent-Free Synthesis

Solvent-free synthesis significantly reduces environmental impact by eliminating hazardous solvents and minimizing waste, aligning with green chemistry principles that prioritize sustainability and safety. This method enhances reaction efficiency and product purity while lowering energy consumption and toxic emissions in chemical manufacturing processes.

Circular Chemistry

Circular chemistry advances green chemistry principles by designing chemical processes that minimize waste, enable the reuse of materials, and reduce reliance on virgin fossil resources, thereby promoting sustainability and resource efficiency. Unlike conventional chemicals that often generate hazardous byproducts, circular chemistry integrates renewable feedstocks and closed-loop systems to create environmentally benign products and processes.

Benign by Design

Benign by Design in green chemistry emphasizes creating chemical products and processes that reduce or eliminate hazardous substances, enhancing environmental and human safety. This approach integrates toxicity assessment early in development, promoting sustainable chemical innovation over traditional chemical methods that often prioritize performance at the expense of safety.

Biodegradable Polymers

Biodegradable polymers represent a pivotal advancement in green chemistry by reducing reliance on traditional petrochemical-based plastics that persist in the environment for centuries. These polymers, derived from renewable resources like starch, cellulose, and polylactic acid (PLA), decompose through natural microbial processes, minimizing ecological impact and supporting sustainable waste management.

Photoredox Catalysis

Photoredox catalysis advances green chemistry by using visible light to drive chemical reactions, reducing the reliance on hazardous reagents and minimizing waste generation. This method enhances the sustainability of chemical synthesis through energy-efficient processes and selective activation of substrates, aligning with environmental and safety objectives in chemical manufacturing.

Microreactor Technology

Microreactor technology revolutionizes chemical processes by enabling precise control over reaction conditions, significantly reducing hazardous waste and energy consumption compared to traditional batch chemistry. This advancement fosters sustainable green chemistry practices through enhanced reaction efficiency, scalability, and safety in the production of fine chemicals, pharmaceuticals, and specialty materials.

Deep Eutectic Solvents

Deep eutectic solvents (DES) represent a promising advancement in green chemistry due to their biodegradable nature, low toxicity, and customizable physicochemical properties compared to traditional volatile organic solvents. These sustainable solvents facilitate environmentally friendly chemical reactions by reducing hazardous waste and energy consumption in industrial processes.

Mechanochemical Synthesis

Mechanochemical synthesis offers a sustainable alternative to traditional chemical processes by utilizing mechanical force to induce reactions without solvents, reducing hazardous waste and energy consumption. This green chemistry approach enhances reaction efficiency and selectivity, aligning with environmental safety and resource conservation goals in chemical manufacturing.

Chemicals vs Green Chemistry Infographic

industrydif.com

industrydif.com