Barcode scanning offers a cost-effective and straightforward solution for inventory tracking with high accuracy in line-of-sight environments, while Radio Frequency Identification (RFID) provides faster data capture and the ability to scan multiple items simultaneously without direct visual contact. Warehouses prioritizing seamless efficiency and real-time asset tracking benefit from RFID's advanced automation capabilities, whereas barcode scanning remains ideal for operations with budget constraints and simpler inventory needs. Choosing between barcode scanning and RFID depends on factors like inventory size, required scanning speed, and the complexity of warehouse layout.

Table of Comparison

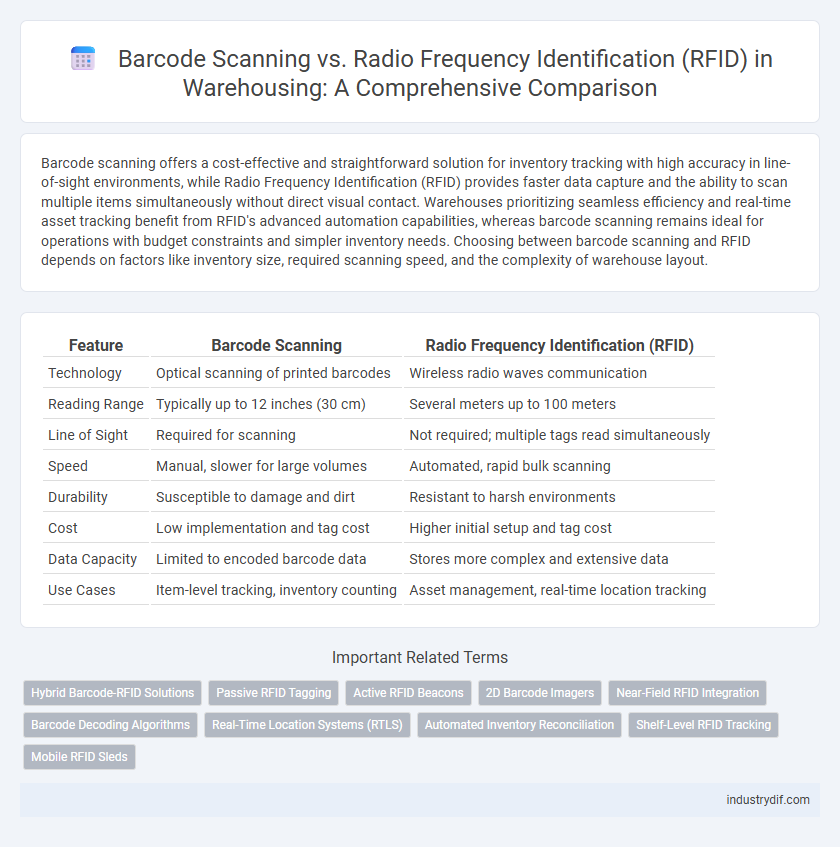

| Feature | Barcode Scanning | Radio Frequency Identification (RFID) |

|---|---|---|

| Technology | Optical scanning of printed barcodes | Wireless radio waves communication |

| Reading Range | Typically up to 12 inches (30 cm) | Several meters up to 100 meters |

| Line of Sight | Required for scanning | Not required; multiple tags read simultaneously |

| Speed | Manual, slower for large volumes | Automated, rapid bulk scanning |

| Durability | Susceptible to damage and dirt | Resistant to harsh environments |

| Cost | Low implementation and tag cost | Higher initial setup and tag cost |

| Data Capacity | Limited to encoded barcode data | Stores more complex and extensive data |

| Use Cases | Item-level tracking, inventory counting | Asset management, real-time location tracking |

Introduction to Barcode Scanning and RFID

Barcode scanning involves reading visual patterns encoded in barcodes using laser or camera-based scanners to quickly identify products, assets, or inventory in warehousing environments. Radio Frequency Identification (RFID) technology uses electromagnetic fields to automatically identify and track tags attached to objects, allowing real-time data capture without direct line-of-sight scanning. Both barcode scanning and RFID are essential tools in supply chain management, enhancing accuracy and efficiency in inventory control.

How Barcode Scanning Works in Warehousing

Barcode scanning in warehousing involves the use of optical scanners to read printed barcodes on products and inventory labels, converting the captured data into digital information for real-time tracking. Each barcode encodes unique product details such as SKU, batch number, and location, enabling accurate stock management and faster order fulfillment. This technology enhances inventory accuracy by minimizing human errors during data entry and streamlining warehouse operations with efficient scanning processes.

How RFID Technology Operates in Warehousing

RFID technology operates in warehousing by using radio waves to automatically identify and track tags attached to inventory items, enabling real-time asset management without direct line-of-sight scanning. RFID systems consist of tags embedded with microchips and antennas, readers that emit radio signals to energize the tags and capture their data, and backend software that processes the information for inventory control. This method increases efficiency by allowing multiple items to be scanned simultaneously and reduces errors compared to barcode scanning, which requires manual line-of-sight reading.

Accuracy and Reliability: Barcode vs RFID

Barcode scanning offers high accuracy when items are properly aligned and undamaged, yet it can suffer from misreads due to poor visibility or scanning angle. RFID systems provide enhanced reliability by enabling non-line-of-sight scanning and simultaneous reading of multiple tags, significantly reducing human error. RFID's robust data capture capabilities increase inventory accuracy, making it ideal for environments requiring real-time tracking and minimal manual intervention.

Speed and Efficiency in Inventory Management

Barcode scanning offers rapid item identification with a scan rate of up to 200 scans per minute, making it efficient for individual product tracking in warehouses. Radio Frequency Identification (RFID) enhances speed by enabling simultaneous reading of multiple tags, significantly reducing inventory audit times by up to 90% compared to barcode methods. RFID's automated data capture improves overall inventory accuracy and operational efficiency, especially in large-scale warehouse environments requiring real-time asset visibility.

Cost Comparison: Barcode Scanning vs RFID

Barcode scanning systems generally have lower initial setup costs compared to RFID technology, making them more affordable for small to medium-sized warehouses. RFID offers higher durability and faster data collection but requires significant investment in tags, readers, and software infrastructure. Over time, RFID can reduce labor costs and errors, potentially providing better return on investment despite its higher upfront expenses.

Implementation Challenges and Considerations

Barcode scanning requires line-of-sight access and can be hindered by dirt or damage to labels, making it less reliable in high-traffic or harsh warehouse environments. Radio Frequency Identification (RFID) systems involve higher initial costs and require careful planning around tag placement, interference sources, and integration with existing warehouse management software. Both technologies demand staff training and maintenance protocols to ensure consistent accuracy and operational efficiency.

Data Security and Traceability

Barcode scanning relies on optical technology that requires line-of-sight and is susceptible to damage or misreads, potentially compromising data accuracy and traceability in warehousing operations. Radio Frequency Identification (RFID) uses radio waves for non-line-of-sight data capture, offering enhanced security features such as encryption and password protection to safeguard sensitive inventory information. RFID systems improve traceability through real-time tracking and automated data collection, reducing human errors and providing a more secure, reliable method for monitoring warehouse inventory compared to barcode scanning.

Scalability and Future-Proofing Warehouse Operations

Barcode scanning offers cost-effective scalability for warehousing but requires manual line-of-sight, limiting speed and accuracy in high-volume environments. Radio Frequency Identification (RFID) enables rapid, contactless data capture suitable for large-scale operations with real-time inventory tracking, enhancing future-proofing through seamless integration with IoT and automation technologies. Investing in RFID supports evolving warehouse demands by improving operational efficiency, scalability, and adaptability to emerging industry standards.

Choosing the Right Solution for Your Warehouse

Barcode scanning provides a cost-effective and simple solution for inventory tracking with widespread compatibility and easy implementation in warehouse environments. Radio Frequency Identification (RFID) offers faster data capture, real-time visibility, and hands-free operation, ideal for high-volume or complex warehouse operations requiring enhanced accuracy. Selecting the right solution depends on factors such as inventory size, budget constraints, operational speed needs, and integration with existing warehouse management systems.

Related Important Terms

Hybrid Barcode-RFID Solutions

Hybrid barcode-RFID solutions integrate barcode scanning and RFID technology to maximize inventory accuracy and operational efficiency in warehousing. Combining the low cost and simplicity of barcodes with the rapid, contactless data capture of RFID enhances real-time tracking, reduces errors, and accelerates order fulfillment processes.

Passive RFID Tagging

Passive RFID tagging in warehousing offers faster, contactless inventory tracking compared to barcode scanning, enabling real-time data capture without line-of-sight requirements. Unlike barcodes, passive RFID tags are more durable and can be read simultaneously in bulk, enhancing efficiency in large-scale stock management.

Active RFID Beacons

Active RFID Beacons in warehousing offer real-time location tracking and longer read ranges compared to traditional barcode scanning, enhancing inventory visibility and operational efficiency. Unlike barcode scanning, which requires line-of-sight and manual scanning, Active RFID Beacons transmit signals continuously, enabling automated asset tracking and reducing human error.

2D Barcode Imagers

2D barcode imagers in warehousing offer precise, high-speed scanning of complex codes, enabling quick inventory tracking and reducing human error compared to traditional RFID systems. Their ability to capture detailed visual data from various angles enhances accuracy in stock management and asset identification within dynamic warehouse environments.

Near-Field RFID Integration

Near-field RFID integration enhances warehouse efficiency by enabling rapid, contactless inventory tracking compared to traditional barcode scanning, which requires line-of-sight and manual scanning. This technology reduces human error and accelerates the processing of stock movements, improving real-time asset visibility and inventory accuracy in distribution centers.

Barcode Decoding Algorithms

Barcode decoding algorithms in warehousing prioritize speed and accuracy to enhance inventory management, employing techniques such as edge detection and error correction to interpret diverse barcode symbologies. Advanced algorithms leverage machine learning models to reduce misreads in challenging environments, outperforming traditional Radio Frequency Identification (RFID) systems in cost-effectiveness and ease of integration for small to medium enterprises.

Real-Time Location Systems (RTLS)

Barcode scanning relies on line-of-sight scanning for inventory tracking, whereas Radio Frequency Identification (RFID) enhances Real-Time Location Systems (RTLS) by providing automatic, non-line-of-sight tracking of assets, improving accuracy and efficiency in warehouse operations. RFID-based RTLS enables continuous, real-time visibility of inventory location and movement, reducing errors and accelerating order fulfillment compared to traditional barcode methods.

Automated Inventory Reconciliation

Barcode scanning offers accurate and cost-effective automated inventory reconciliation by quickly capturing item data during warehouse operations, but it requires line-of-sight and manual scanning for each product. Radio Frequency Identification (RFID) enhances inventory tracking with non-line-of-sight, bulk scanning capability, significantly speeding up automated reconciliation processes and reducing human error in large-scale warehouses.

Shelf-Level RFID Tracking

Shelf-level RFID tracking enhances warehouse inventory accuracy by providing real-time, contactless data collection across multiple items simultaneously, outperforming traditional barcode scanning which requires line-of-sight and manual scanning. RFID systems reduce labor costs and human error while enabling dynamic shelf management and improved stock visibility for efficient replenishment and loss prevention.

Mobile RFID Sleds

Mobile RFID sleds enhance warehousing efficiency by combining handheld barcode scanning capabilities with RFID technology, enabling faster inventory tracking and real-time data capture. Unlike traditional barcode scanners, these sleds read multiple RFID tags simultaneously without line-of-sight, significantly reducing manual errors and improving asset visibility across large storage facilities.

Barcode Scanning vs Radio Frequency Identification Infographic

industrydif.com

industrydif.com