Order batching consolidates multiple orders into a single pick run, enhancing efficiency by reducing travel time and minimizing picking errors in warehouses. Wave picking schedules order fulfillment in defined time slots, optimizing labor allocation and synchronizing picking with shipping deadlines. Choosing between order batching and wave picking depends on warehouse size, order volume, and the need for speed versus accuracy.

Table of Comparison

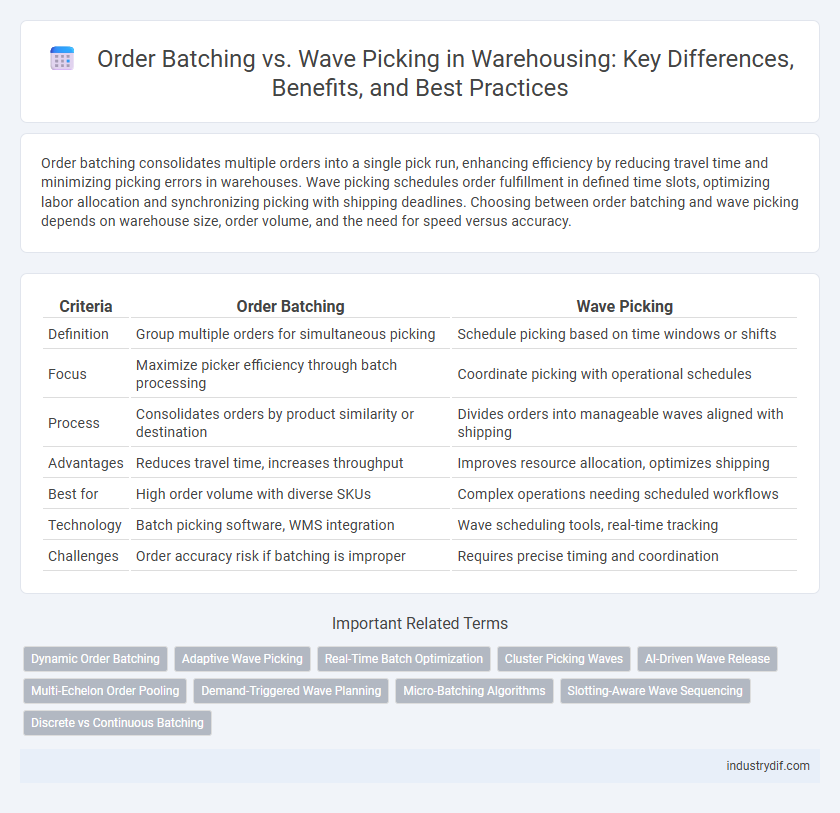

| Criteria | Order Batching | Wave Picking |

|---|---|---|

| Definition | Group multiple orders for simultaneous picking | Schedule picking based on time windows or shifts |

| Focus | Maximize picker efficiency through batch processing | Coordinate picking with operational schedules |

| Process | Consolidates orders by product similarity or destination | Divides orders into manageable waves aligned with shipping |

| Advantages | Reduces travel time, increases throughput | Improves resource allocation, optimizes shipping |

| Best for | High order volume with diverse SKUs | Complex operations needing scheduled workflows |

| Technology | Batch picking software, WMS integration | Wave scheduling tools, real-time tracking |

| Challenges | Order accuracy risk if batching is improper | Requires precise timing and coordination |

Understanding Order Batching in Warehousing

Order batching in warehousing involves grouping multiple customer orders into a single batch to optimize picking efficiency and reduce travel time for warehouse workers. By consolidating orders based on criteria such as item location, order priority, or shipment deadlines, warehouses can minimize repetitive trips and improve throughput. This method contrasts with wave picking by focusing on collective order fulfillment rather than time-based picking cycles.

What Is Wave Picking?

Wave picking is a warehouse order fulfillment method that organizes pick tasks into scheduled waves based on specific criteria such as shipping deadlines, carrier schedules, or product characteristics. This approach optimizes labor efficiency by synchronizing picking activities with packing and shipping processes, reducing bottlenecks and improving throughput. Wave picking is particularly effective in high-volume distribution centers where coordinated task execution enhances overall operational performance.

Key Differences Between Order Batching and Wave Picking

Order batching groups multiple orders together for simultaneous picking, maximizing picker efficiency by reducing travel time within the warehouse. Wave picking organizes orders into timed batches aligned with shipping schedules, ensuring synchronized loading and dispatch. The primary difference lies in batching criteria: order batching prioritizes pick efficiency, while wave picking coordinates picking with overall warehouse workflow and shipping deadlines.

Advantages of Order Batching

Order batching in warehousing optimizes pick efficiency by grouping multiple orders with common SKUs, reducing travel time and labor costs. This method enhances inventory accuracy and streamlines packing processes, leading to faster order fulfillment. Batching also supports higher throughput in environments with high order volumes and diverse item assortments.

Advantages of Wave Picking

Wave picking improves warehouse efficiency by grouping orders based on specific criteria such as shipping deadlines, product types, or delivery routes, reducing travel time for pickers. It enhances labor coordination and resource allocation by synchronizing picking activities with packing and shipping schedules. This method minimizes bottlenecks and increases order accuracy, leading to faster fulfillment and better customer satisfaction.

Challenges and Limitations of Order Batching

Order batching in warehousing often faces challenges such as increased pick errors and inventory inaccuracies due to combining multiple orders into one batch. The method can lead to longer processing times and inefficiencies when handling high-variance order profiles or diverse SKU mixes. Order batching also struggles with scalability issues in large operations, limiting responsiveness to urgent or short-deadline orders.

Challenges and Limitations of Wave Picking

Wave picking in warehousing faces challenges such as increased complexity in scheduling and coordination across multiple orders, which can lead to delays and inefficiencies. Limitations include higher dependency on accurate demand forecasting and potential bottlenecks during peak periods, impacting overall throughput. This method also struggles with variability in order size and product diversity, reducing its effectiveness for warehouses with heterogeneous inventory profiles.

Technology Impact on Picking Methods

Advanced warehouse management systems (WMS) have revolutionized order batching by using real-time data to optimize batch size and reduce picker travel time, significantly enhancing efficiency. Wave picking benefits from technology through synchronized scheduling and automated task allocation, allowing simultaneous handling of multiple orders synchronized by shipping deadlines. Integration of RFID and voice-directed picking technologies in both methods further accelerates accuracy and reduces processing time, transforming traditional picking workflows into highly streamlined operations.

Selecting the Right Picking Strategy for Your Warehouse

Order batching combines multiple orders into a single pick run, optimizing travel time for warehouses with high order volumes and similar item locations. Wave picking schedules pick tasks based on specific criteria like shipping deadlines or product types, ideal for complex operations requiring coordinated workflows. Selecting the right picking strategy depends on order profiles, warehouse layout, and fulfillment speed requirements to maximize efficiency and reduce labor costs.

Future Trends in Order Picking Optimization

Future trends in order picking optimization emphasize integrating AI-driven analytics to enhance both order batching and wave picking methods, improving accuracy and speed. Robotics and automated guided vehicles (AGVs) are increasingly deployed to streamline workflows, minimizing labor costs and reducing picking errors. Advanced warehouse management systems (WMS) leverage real-time data to dynamically adjust picking strategies, driving higher efficiency in complex distribution environments.

Related Important Terms

Dynamic Order Batching

Dynamic order batching optimizes warehouse efficiency by grouping orders based on real-time data such as item demand, picker location, and order priority, reducing travel time and improving throughput compared to static batching methods. Unlike wave picking, which releases orders at fixed intervals, dynamic order batching continuously adapts to operational conditions, enhancing flexibility and responsiveness in fast-paced fulfillment environments.

Adaptive Wave Picking

Adaptive Wave Picking enhances order fulfillment efficiency by dynamically grouping orders based on real-time warehouse conditions and priorities, reducing travel time and labor costs compared to traditional order batching. This method utilizes data analytics and warehouse management systems to optimize picking sequences, improving throughput and accuracy in complex distribution environments.

Real-Time Batch Optimization

Real-time batch optimization in warehousing enables dynamic adjustment of order batching by analyzing incoming order data and warehouse conditions, significantly improving picker efficiency and reducing fulfillment time. Wave picking, though scheduled, benefits from real-time updates by synchronizing labor and equipment deployment, optimizing resource allocation across multiple picking zones.

Cluster Picking Waves

Cluster picking waves group multiple orders into a single wave to optimize labor efficiency by reducing travel time and improving picking accuracy. Combining cluster picking with wave-based scheduling streamlines warehouse operations, increases throughput, and minimizes order processing delays.

AI-Driven Wave Release

AI-driven wave release in warehousing optimizes order batching by dynamically grouping orders based on real-time demand, picker availability, and inventory locations, significantly reducing picking time and increasing throughput. This intelligent system enhances wave picking efficiency by predicting workload and adjusting batch sizes, resulting in improved accuracy and operational flexibility.

Multi-Echelon Order Pooling

Multi-echelon order pooling optimizes warehousing by consolidating orders across different inventory locations before batch processing, enhancing efficiency compared to traditional order batching methods. Wave picking schedules order fulfillment in planned intervals, but multi-echelon pooling reduces redundancy by synchronizing multi-location inventory flows, resulting in faster throughput and lower picking costs.

Demand-Triggered Wave Planning

Demand-triggered wave planning in warehousing optimizes order fulfillment by grouping orders based on real-time demand signals, enhancing efficiency compared to traditional order batching. This method reduces picker idle time and increases throughput by dynamically aligning picking waves with fluctuating customer demand and inventory availability.

Micro-Batching Algorithms

Micro-batching algorithms optimize order batching by dividing large order groups into smaller, manageable subsets to reduce picking time and increase accuracy. Compared to traditional wave picking, micro-batching enhances real-time responsiveness and inventory synchronization, improving overall warehouse operational efficiency.

Slotting-Aware Wave Sequencing

Slotting-aware wave sequencing enhances wave picking efficiency by aligning order batches with optimal storage locations, reducing travel time and improving picker productivity. Integrating dynamic slotting data into wave sequencing algorithms ensures that high-velocity items are prioritized within organized zones, streamlining order fulfillment and minimizing labor costs.

Discrete vs Continuous Batching

Order batching in warehousing groups discrete, predefined orders for picking, enhancing accuracy and minimizing handling errors, while wave picking employs continuous batching by releasing pick tasks in timed waves to maximize labor utilization and streamline workflow efficiency. Discrete batching suits low-variability demand environments, whereas continuous wave picking adapts better to high-volume, dynamic order profiles requiring real-time responsiveness.

Order Batching vs Wave Picking Infographic

industrydif.com

industrydif.com