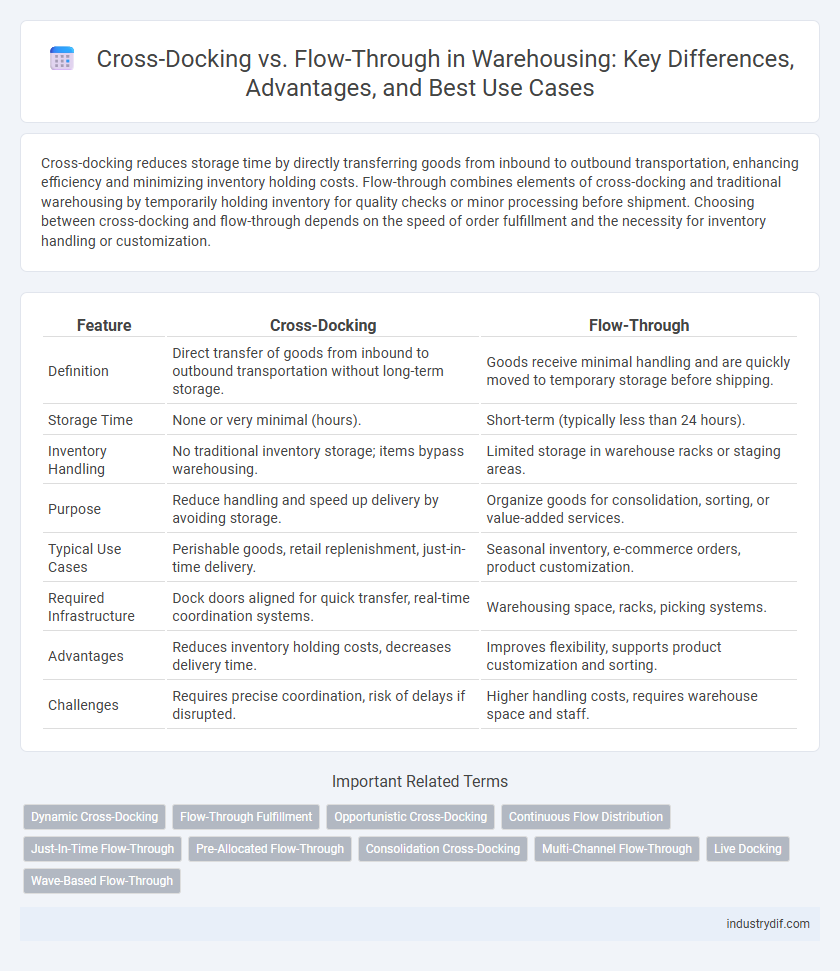

Cross-docking reduces storage time by directly transferring goods from inbound to outbound transportation, enhancing efficiency and minimizing inventory holding costs. Flow-through combines elements of cross-docking and traditional warehousing by temporarily holding inventory for quality checks or minor processing before shipment. Choosing between cross-docking and flow-through depends on the speed of order fulfillment and the necessity for inventory handling or customization.

Table of Comparison

| Feature | Cross-Docking | Flow-Through |

|---|---|---|

| Definition | Direct transfer of goods from inbound to outbound transportation without long-term storage. | Goods receive minimal handling and are quickly moved to temporary storage before shipping. |

| Storage Time | None or very minimal (hours). | Short-term (typically less than 24 hours). |

| Inventory Handling | No traditional inventory storage; items bypass warehousing. | Limited storage in warehouse racks or staging areas. |

| Purpose | Reduce handling and speed up delivery by avoiding storage. | Organize goods for consolidation, sorting, or value-added services. |

| Typical Use Cases | Perishable goods, retail replenishment, just-in-time delivery. | Seasonal inventory, e-commerce orders, product customization. |

| Required Infrastructure | Dock doors aligned for quick transfer, real-time coordination systems. | Warehousing space, racks, picking systems. |

| Advantages | Reduces inventory holding costs, decreases delivery time. | Improves flexibility, supports product customization and sorting. |

| Challenges | Requires precise coordination, risk of delays if disrupted. | Higher handling costs, requires warehouse space and staff. |

Definition of Cross-Docking

Cross-docking is a warehousing strategy where inbound shipments are directly transferred to outbound transportation with minimal or no storage time, enhancing order fulfillment speed and reducing inventory holding costs. This process streamlines supply chain operations by consolidating products from various suppliers and quickly sorting them for immediate dispatch to customers or retail locations. Cross-docking reduces handling, minimizes warehouse space usage, and improves overall efficiency compared to traditional flow-through warehousing, which involves longer storage periods before distribution.

Understanding Flow-Through Distribution

Flow-through distribution in warehousing streamlines product movement by transferring goods directly from receiving to outbound shipping without long-term storage, reducing handling time and inventory costs. This method enhances efficiency by minimizing delays and optimizing space utilization compared to traditional cross-docking, which may involve sorting and temporary staging of products. Implementing flow-through distribution supports faster order fulfillment and improved supply chain responsiveness, critical for high-volume, time-sensitive operations.

Key Differences Between Cross-Docking and Flow-Through

Cross-docking streamlines inventory movement by directly transferring products from inbound to outbound transportation with minimal storage, reducing handling time and storage costs. Flow-through warehousing involves sorting and temporarily storing goods before they are shipped, enabling better order customization and inventory accuracy. Key differences include the level of inventory holding, processing time, and the complexity of order fulfillment strategies.

Advantages of Cross-Docking

Cross-docking significantly reduces storage costs and speeds up order fulfillment by minimizing inventory holding times. This warehousing method improves supply chain efficiency through direct transfer of goods from inbound to outbound transportation. Enhanced inventory control and reduced labor expenses are additional advantages that make cross-docking a preferred strategy in logistics management.

Benefits of Flow-Through Warehousing

Flow-through warehousing streamlines inventory processes by minimizing storage time and accelerating product movement from receiving to shipping. This method reduces handling costs and lowers the risk of inventory obsolescence, enhancing supply chain efficiency. Retailers benefit from improved order accuracy and faster replenishment cycles, meeting consumer demand more effectively.

Operational Processes Compared

Cross-docking optimizes supply chain efficiency by directly transferring inbound goods to outbound transportation with minimal storage time, reducing inventory holding costs and accelerating order fulfillment. Flow-through integrates inventory storage with order picking, allowing stock to be received, stored, and processed simultaneously, enhancing accuracy and flexibility in order management. Operationally, cross-docking demands precise scheduling and rapid material handling, whereas flow-through relies on warehouse management systems to synchronize receiving, storage, and picking activities.

Ideal Scenarios for Cross-Docking

Cross-docking is ideal for high-volume, time-sensitive products such as perishable goods, where minimizing storage time reduces spoilage and handling costs. It excels in environments with well-coordinated supplier and retailer schedules, enabling rapid transfer of inventory from inbound to outbound transportation without long-term warehousing. This approach is particularly effective in retail distribution centers, grocery supply chains, and just-in-time manufacturing systems where speed and efficiency are critical.

Best Use Cases for Flow-Through

Flow-through warehousing excels in retail environments requiring rapid order fulfillment and minimal inventory holding by directly transferring inbound goods to outbound shipment without intermediate storage. It is ideal for e-commerce operations with high SKU variability and frequent order customization, enabling reduced lead times and lower handling costs. This strategy optimizes space utilization and improves supply chain responsiveness in high-demand, fast-moving product scenarios.

Challenges and Limitations

Cross-docking faces challenges such as high coordination demands and limited storage flexibility due to its reliance on immediate transfer of goods, which can lead to delays if inbound and outbound schedules are not perfectly aligned. Flow-through operations struggle with inventory management complexities and require robust warehouse management systems to efficiently transition products without excessive handling time. Both methods are constrained by infrastructure requirements and labor skill levels, impacting overall throughput and operational efficiency.

Key Metrics for Performance Evaluation

Cross-docking efficiency is measured by dock-to-stock cycle time, inventory turnover rates, and reduced handling costs, indicating faster movement and minimal storage. Flow-through performance focuses on order cycle time, fill rate, and throughput volume, reflecting seamless integration between inbound and outbound logistics. Key metrics such as order accuracy and labor productivity apply to both, driving cost-effective and timely distribution in warehousing operations.

Related Important Terms

Dynamic Cross-Docking

Dynamic Cross-Docking streamlines inventory movement by synchronizing inbound and outbound shipments without storage, significantly reducing handling time and warehouse space compared to traditional Flow-Through operations. This method enhances supply chain efficiency by enabling real-time routing adjustments and minimizing order processing delays in high-velocity distribution environments.

Flow-Through Fulfillment

Flow-through fulfillment streamlines order processing by directly moving inbound shipments to outbound shipping without storage, significantly reducing handling times and inventory costs. This method enhances warehouse efficiency and accelerates delivery by minimizing delays inherent in traditional storage-based systems.

Opportunistic Cross-Docking

Opportunistic cross-docking in warehousing involves selectively transferring inbound shipments directly to outbound transportation without storage, optimizing inventory flow and reducing handling costs. Unlike flow-through processing, which typically requires preplanned staging areas, opportunistic cross-docking dynamically leverages real-time demand signals to improve supply chain responsiveness and minimize lead times.

Continuous Flow Distribution

Continuous Flow Distribution in warehousing maximizes efficiency by minimizing storage time between inbound and outbound shipments, unlike traditional Cross-Docking which temporarily holds goods for sorting before dispatch. Flow-Through operations emphasize seamless product movement through the facility, reducing handling costs and accelerating order fulfillment.

Just-In-Time Flow-Through

Just-In-Time Flow-Through warehousing minimizes inventory storage by directly transferring goods from inbound to outbound shipments, enhancing supply chain efficiency and reducing lead times. This method contrasts with traditional cross-docking by emphasizing precise timing and coordination to meet exact delivery schedules, aligning inventory flow tightly with production demands.

Pre-Allocated Flow-Through

Pre-Allocated Flow-Through in warehousing streamlines inventory management by assigning specific warehouse space and handling resources to incoming products, minimizing touchpoints and expediting order fulfillment. This method reduces storage time and operational costs compared to traditional Cross-Docking by enabling direct flow of goods from receiving to shipping without interim storage.

Consolidation Cross-Docking

Consolidation cross-docking streamlines warehousing by directly transferring inbound goods from multiple suppliers to outbound shipments without long-term storage, enhancing efficiency and reducing handling costs. This method contrasts with flow-through operations by emphasizing the aggregation of smaller shipments into full-load dispatches, optimizing transportation and inventory management.

Multi-Channel Flow-Through

Multi-channel flow-through optimizes warehousing by directly transferring incoming goods to outbound shipping lanes, reducing storage time and enabling efficient handling of orders from diverse sales channels. This method contrasts with traditional cross-docking by incorporating inventory staging for multiple channels, improving order accuracy and responsiveness in e-commerce and retail distribution.

Live Docking

Live docking streamlines warehousing operations by allowing goods to be immediately transferred from inbound to outbound transportation without storage, reducing handling time and inventory costs. Unlike traditional cross-docking, live docking emphasizes real-time synchronization of shipments, optimizing flow-through processes for faster delivery and enhanced supply chain efficiency.

Wave-Based Flow-Through

Wave-Based Flow-Through warehousing streamlines inventory movement by consolidating orders into timed waves, allowing for seamless picking and immediate shipping without prolonged storage. Unlike traditional cross-docking, it minimizes handling and improves order accuracy by synchronizing inbound and outbound processes in scheduled intervals.

Cross-Docking vs Flow-Through Infographic

industrydif.com

industrydif.com