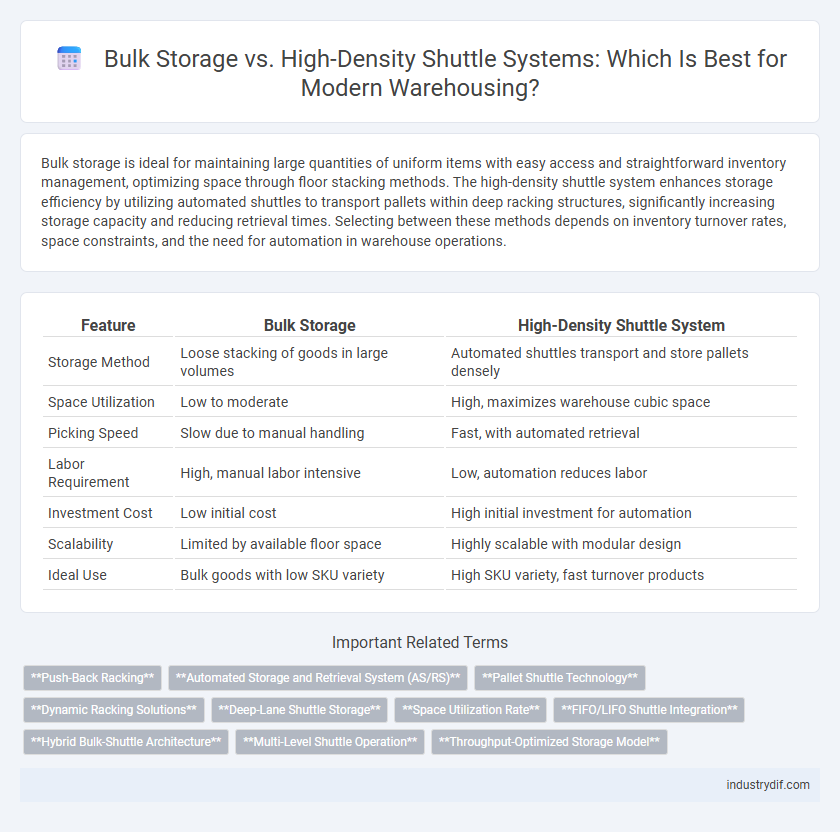

Bulk storage is ideal for maintaining large quantities of uniform items with easy access and straightforward inventory management, optimizing space through floor stacking methods. The high-density shuttle system enhances storage efficiency by utilizing automated shuttles to transport pallets within deep racking structures, significantly increasing storage capacity and reducing retrieval times. Selecting between these methods depends on inventory turnover rates, space constraints, and the need for automation in warehouse operations.

Table of Comparison

| Feature | Bulk Storage | High-Density Shuttle System |

|---|---|---|

| Storage Method | Loose stacking of goods in large volumes | Automated shuttles transport and store pallets densely |

| Space Utilization | Low to moderate | High, maximizes warehouse cubic space |

| Picking Speed | Slow due to manual handling | Fast, with automated retrieval |

| Labor Requirement | High, manual labor intensive | Low, automation reduces labor |

| Investment Cost | Low initial cost | High initial investment for automation |

| Scalability | Limited by available floor space | Highly scalable with modular design |

| Ideal Use | Bulk goods with low SKU variety | High SKU variety, fast turnover products |

Introduction to Bulk Storage and High-Density Shuttle Systems

Bulk storage involves storing large quantities of homogeneous products in open bins or pallets, optimizing space for high-volume inventory with straightforward retrieval methods. High-Density Shuttle Systems use automated shuttles to transport and store pallets within dense racking systems, significantly increasing storage capacity and improving order picking speed. Both methods cater to different warehousing needs, with bulk storage favoring cost-effective space use and shuttle systems enhancing operational efficiency through automation.

Key Principles of Bulk Storage

Bulk storage prioritizes maximizing space utilization by storing large quantities of uniform products in open, often palletized, stacks to facilitate easy access and rapid inventory turnover. It relies on principles such as weight distribution, airflow optimization, and minimizing material handling to improve efficiency and reduce product damage. This method suits businesses managing high-volume, fast-moving goods requiring straightforward retrieval processes.

Overview of High-Density Shuttle Systems

High-density shuttle systems maximize warehouse space by utilizing automated shuttles to transport and store pallets within dense storage racks, significantly increasing storage capacity compared to traditional bulk storage. These systems leverage advanced software for real-time inventory management and rapid retrieval, improving operational efficiency and reducing labor costs. Integration with warehouse management systems (WMS) enhances accuracy and scalability, making high-density shuttles ideal for industries requiring optimized space utilization and fast throughput.

Space Utilization: Bulk Storage vs High-Density Solutions

Bulk storage maximizes space by stacking large quantities of uniform goods, but often underutilizes vertical space due to accessibility constraints. High-density shuttle systems enhance space utilization by enabling automated, multi-level storage and retrieval, significantly increasing pallet slot density. This technology reduces aisle width requirements and optimizes cubic storage capacity, making it ideal for warehouses prioritizing compact, high-throughput operations.

Inventory Accessibility and Retrieval Speed

Bulk storage prioritizes maximizing space by stacking large quantities of goods, which often limits immediate access to individual items and slows retrieval speed. High-density shuttle systems employ automated shuttles to transport inventory within compact racking setups, significantly enhancing accessibility and accelerating order picking processes. Implementing high-density shuttle systems improves operational efficiency by reducing retrieval time and optimizing inventory flow compared to conventional bulk storage methods.

Operational Efficiency Comparison

Bulk storage warehouses excel in handling large volumes of homogeneous products with straightforward, easy access, enabling fast loading and unloading processes ideal for low SKU variability. High-Density Shuttle Systems maximize space utilization by automating retrieval and storage within compact aisles, significantly boosting throughput and reducing labor costs in facilities managing diverse SKUs. Operational efficiency in bulk storage relies on manual labor and wide aisles for accessibility, whereas high-density shuttles leverage automation and optimized storage algorithms to enhance inventory velocity and minimize handling errors.

Safety and Risk Management

Bulk storage in warehousing offers straightforward organization but poses higher risks of product damage and worker injury due to limited access and manual handling. The high-density shuttle system enhances safety by automating storage retrieval, reducing human error and accident rates while optimizing space utilization. Implementing advanced sensors and real-time monitoring within shuttle systems further mitigates risks, ensuring compliance with safety regulations and minimizing operational hazards.

Cost Implications and ROI

Bulk storage systems typically require lower upfront capital investment due to simpler infrastructure and less automation, resulting in slower ROI but reduced initial costs. High-density shuttle systems demand significant initial expenditure for advanced robotics and software integration, accelerating ROI through enhanced space utilization and increased throughput. Evaluating operational volume and long-term scalability is critical to determine the most cost-effective warehousing solution with optimal return on investment.

Industry Use Cases and Best Applications

Bulk storage is ideal for industries handling large volumes of uniform products such as raw materials in manufacturing or retail inventory with lower SKU variability, providing cost-effective, easy-access storage. High-density shuttle systems excel in e-commerce and pharmaceuticals where fast retrieval and space optimization are critical, enabling automated handling of diverse SKUs with high throughput and improved accuracy. Selecting between bulk storage and shuttle systems depends on product volume, SKU diversity, retrieval speed, and warehouse footprint requirements in the specific industry.

Future Trends in Industrial Warehousing Solutions

Future trends in industrial warehousing emphasize automation and space optimization, where high-density shuttle systems offer increased storage capacity and faster retrieval compared to traditional bulk storage. Integration of AI-driven inventory management and robotics enhances operational efficiency and reduces labor costs. Sustainability initiatives drive the adoption of energy-efficient technologies within these advanced storage solutions, shaping the evolution of warehouse design and functionality.

Related Important Terms

Push-Back Racking

Push-back racking in warehousing offers a space-efficient bulk storage solution by allowing multiple pallets to be stored on a slight incline, which maximizes storage density and improves retrieval speed compared to traditional shelving. Unlike high-density shuttle systems, push-back racking maintains simpler mechanical operations and reduced investment costs while still optimizing warehouse space for storing large volumes of goods.

Automated Storage and Retrieval System (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) in warehousing offer significant advantages over traditional bulk storage by maximizing space utilization and enhancing inventory accuracy through high-density shuttle systems. These systems enable rapid, automated handling of goods in densely packed aisles, increasing throughput and reducing labor costs while optimizing vertical and horizontal storage capacity.

Pallet Shuttle Technology

Pallet Shuttle Technology enhances bulk storage by using automated shuttles to transport pallets within high-density racks, maximizing space utilization and increasing retrieval speed. This system reduces labor costs and improves inventory accuracy compared to traditional pallet stacking in bulk storage environments.

Dynamic Racking Solutions

Dynamic racking solutions like high-density shuttle systems maximize storage efficiency by enabling automated retrieval and storage of pallets, significantly increasing warehouse throughput compared to traditional bulk storage methods. These systems optimize space utilization by adapting to inventory fluctuations and reducing aisle requirements, improving overall operational agility in warehousing environments.

Deep-Lane Shuttle Storage

Deep-lane shuttle storage leverages automated shuttles to efficiently store and retrieve pallets in deep, narrow lanes, maximizing warehouse cubic space and significantly increasing storage density compared to traditional bulk storage. This high-density shuttle system reduces aisle space, enhances throughput, and optimizes inventory management by enabling faster pallet handling in multi-level racking configurations.

Space Utilization Rate

Bulk storage typically offers a lower space utilization rate, around 60-70%, due to wide aisles and pallet stacking limitations. High-density shuttle systems can achieve space utilization rates exceeding 85%, maximizing vertical and horizontal storage by automating pallet retrieval in narrow aisle environments.

FIFO/LIFO Shuttle Integration

Bulk storage systems generally support FIFO inventory management due to their straightforward layout, while high-density shuttle systems excel in integrating both FIFO and LIFO processes through automated shuttle movements that optimize retrieval and storage efficiency. High-density shuttle systems enhance inventory accuracy and space utilization by dynamically managing product rotation, which is crucial for perishable or time-sensitive goods.

Hybrid Bulk-Shuttle Architecture

Hybrid Bulk-Shuttle Architecture combines the expansive capacity of bulk storage with the precision and efficiency of high-density shuttle systems, maximizing warehouse throughput and space utilization. This integration leverages automated shuttle technology to facilitate rapid retrieval and inventory management within bulk storage environments, driving operational cost savings and scalability.

Multi-Level Shuttle Operation

Multi-level shuttle systems optimize warehouse space by enabling automated storage and retrieval across multiple tiers, significantly increasing storage density compared to traditional bulk storage. These shuttles operate efficiently within narrow aisles and stacked racks, improving throughput and reducing labor costs while maintaining fast access to inventory items.

Throughput-Optimized Storage Model

Bulk storage maximizes volume by stacking large quantities of goods but often compromises throughput due to limited pick access, while the high-density shuttle system enhances throughput through automated shuttle technology that enables rapid, direct retrieval and replenishment. Throughput-optimized storage models prioritize minimizing picking time and maximizing inventory accessibility, making high-density shuttle systems superior for dynamic, fast-moving warehouse environments.

Bulk Storage vs High-Density Shuttle System Infographic

industrydif.com

industrydif.com