Traditional warehousing typically involves large storage facilities located outside urban centers, designed for bulk inventory management and long-term storage. Micro-fulfillment centers operate within or near urban areas, leveraging automation and technology to enable rapid order processing and last-mile delivery. This shift enhances supply chain efficiency by reducing delivery times and addressing the growing demand for e-commerce fulfillment.

Table of Comparison

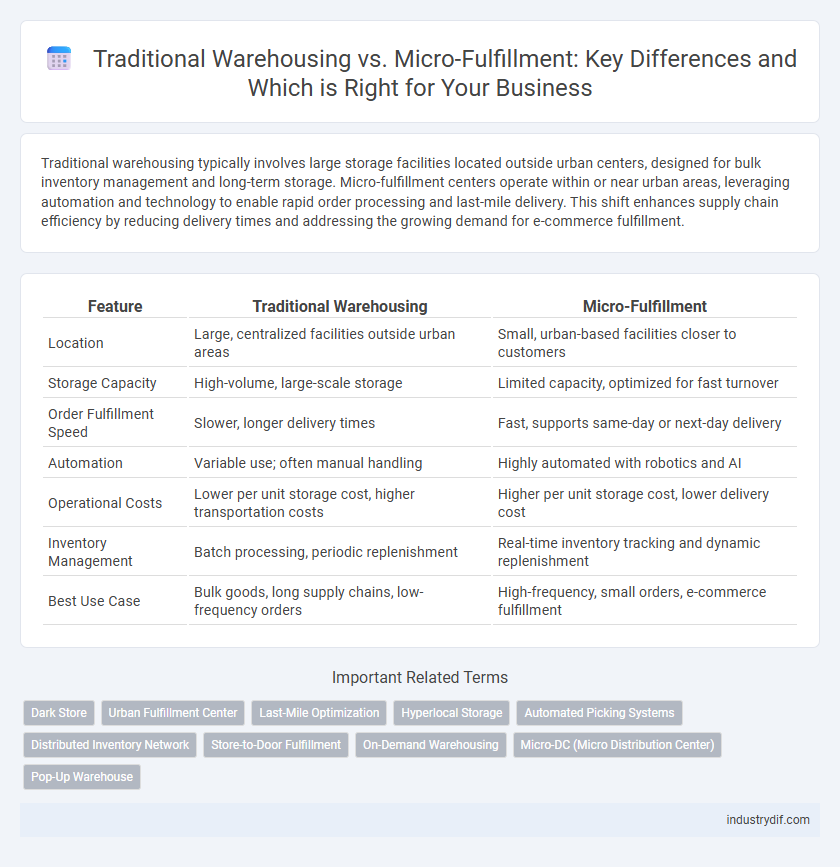

| Feature | Traditional Warehousing | Micro-Fulfillment |

|---|---|---|

| Location | Large, centralized facilities outside urban areas | Small, urban-based facilities closer to customers |

| Storage Capacity | High-volume, large-scale storage | Limited capacity, optimized for fast turnover |

| Order Fulfillment Speed | Slower, longer delivery times | Fast, supports same-day or next-day delivery |

| Automation | Variable use; often manual handling | Highly automated with robotics and AI |

| Operational Costs | Lower per unit storage cost, higher transportation costs | Higher per unit storage cost, lower delivery cost |

| Inventory Management | Batch processing, periodic replenishment | Real-time inventory tracking and dynamic replenishment |

| Best Use Case | Bulk goods, long supply chains, low-frequency orders | High-frequency, small orders, e-commerce fulfillment |

Introduction to Traditional Warehousing and Micro-Fulfillment

Traditional warehousing involves centralized storage facilities that manage large inventories with manual or semi-automated handling, supporting bulk storage and long-term goods preservation. Micro-fulfillment centers are compact, technology-driven hubs located near urban areas designed to accelerate order processing and support last-mile delivery with automated systems. Both warehousing models optimize supply chain efficiency but cater to different business needs and delivery speeds.

Key Differences Between Traditional Warehousing and Micro-Fulfillment

Traditional warehousing typically involves large-scale storage facilities located on the outskirts of urban areas, prioritizing high-volume inventory and bulk shipping, while micro-fulfillment centers operate within or near urban centers, emphasizing speed and proximity to customers for rapid order fulfillment. Traditional warehouses rely heavily on manual processes and larger workforce, whereas micro-fulfillment uses advanced automation, robotics, and AI-driven systems to optimize space and operational efficiency. Inventory management in traditional warehousing focuses on bulk storage with longer lead times, contrasting micro-fulfillment's focus on smaller, more frequent inventory turnover aligned with omni-channel retail demands.

Warehouse Location: Central Hubs vs Urban Proximity

Traditional warehousing relies on large, centralized hubs located on city outskirts or industrial zones to maximize storage capacity and streamline bulk distribution. Micro-fulfillment centers prioritize urban proximity, positioning smaller, highly automated warehouses close to dense population centers to reduce last-mile delivery times and enhance customer responsiveness. The strategic location difference directly impacts supply chain efficiency, with central hubs optimizing inventory consolidation and micro-fulfillment centers enabling rapid order fulfillment in e-commerce-driven markets.

Storage Technologies and Automation

Traditional warehousing relies heavily on large-scale storage technologies such as pallet racking and manual picking systems, which often result in slower inventory access and increased labor costs. Micro-fulfillment centers use advanced automation technologies including robotics, automated conveyors, and AI-driven inventory management to maximize space efficiency and expedite order processing. Implementing micro-fulfillment solutions enhances storage density and operational speed compared to conventional warehouses, driving significant improvements in supply chain responsiveness.

Order Processing Speed and Efficiency

Traditional warehousing relies on large storage facilities with manual or semi-automated processes, resulting in longer order processing times and lower operational efficiency. Micro-fulfillment centers, often located closer to end customers and equipped with advanced automation technologies, significantly reduce order processing speed and enhance efficiency by enabling rapid picking and packing. Faster order fulfillment in micro-fulfillment directly supports same-day delivery demands, optimizing inventory turnover and reducing transportation costs.

Inventory Management Practices

Traditional warehousing relies on large-scale storage with periodic manual inventory checks, often resulting in slower replenishment cycles and higher carrying costs. Micro-fulfillment centers utilize automation and real-time inventory tracking, improving accuracy and reducing stockouts by enabling faster order processing closer to the customer. Advanced inventory management software in micro-fulfillment systems optimizes space utilization and demand forecasting, leading to improved operational efficiency compared to conventional warehouses.

Scalability and Flexibility Comparison

Traditional warehousing offers extensive storage capacity suited for large-scale inventory but often lacks the rapid adaptability required for fluctuating order volumes. Micro-fulfillment centers provide enhanced scalability through modular designs and proximity to end consumers, allowing for dynamic adjustment of inventory and quicker response times. The flexibility of micro-fulfillment systems supports diverse product assortments and seasonal demand shifts more efficiently than traditional warehousing models.

Cost Structures and Operational Expenses

Traditional warehousing incurs higher fixed costs due to large facility sizes, extensive labor requirements, and significant inventory holding expenses. Micro-fulfillment centers reduce operational expenses by optimizing space usage and leveraging automation to lower labor costs and improve inventory turnover rates. These cost structures make micro-fulfillment more scalable and adaptable to fluctuating consumer demand compared to traditional warehousing.

Impact on Last-Mile Delivery

Traditional warehousing centralizes inventory in large facilities, often located far from urban centers, leading to longer last-mile delivery times and higher transportation costs. Micro-fulfillment centers, strategically placed within or near urban areas, significantly reduce delivery distances, enabling faster and more cost-efficient last-mile fulfillment. This shift enhances customer satisfaction through quicker order processing and supports the growing demand for same-day or next-day delivery services.

Future Trends in Warehousing Solutions

Future trends in warehousing highlight a shift from traditional warehousing, characterized by large, centralized storage facilities, to micro-fulfillment centers that prioritize proximity to consumers for faster delivery. Micro-fulfillment leverages advanced automation, robotics, and AI-driven inventory management, enabling real-time order processing and reducing last-mile delivery costs. Increased urbanization and e-commerce growth drive adoption of compact, technology-enhanced warehouses that optimize space utilization and enhance operational agility.

Related Important Terms

Dark Store

Traditional warehousing typically features large storage facilities located on the outskirts of urban areas, designed for bulk inventory storage and long-term stock management. In contrast, micro-fulfillment centers, often operating as dark stores, are smaller, automated facilities strategically placed within cities to enable rapid order processing and last-mile delivery efficiency.

Urban Fulfillment Center

Traditional warehousing involves large, centralized facilities located on city outskirts, prioritizing bulk storage and long-term inventory management, whereas micro-fulfillment centers are compact, technology-driven urban fulfillment hubs designed to expedite last-mile delivery and enhance order accuracy. Urban fulfillment centers optimize space using automation and AI to handle high order volumes swiftly, significantly reducing delivery times and transportation costs compared to conventional warehousing models.

Last-Mile Optimization

Traditional warehousing relies on large, centralized facilities that often increase last-mile delivery costs and extend lead times due to distance from end customers. Micro-fulfillment centers, strategically located near urban areas, optimize last-mile efficiency by reducing delivery time and transportation expenses through closer proximity to consumers.

Hyperlocal Storage

Traditional warehousing relies on large, centralized facilities that prioritize bulk storage and extended inventory holding, resulting in longer delivery times for hyperlocal demand. Micro-fulfillment centers utilize compact, technology-driven spaces strategically located near urban hubs to enable rapid order processing and same-day delivery in hyperlocal markets.

Automated Picking Systems

Traditional warehousing relies heavily on manual picking processes, leading to slower order fulfillment and increased labor costs, whereas micro-fulfillment centers utilize automated picking systems such as robotic shuttles and conveyor belts to accelerate accuracy and throughput in dense urban environments. Automated solutions in micro-fulfillment optimize space utilization and reduce human error, enhancing efficiency and scalability for e-commerce and last-mile delivery operations.

Distributed Inventory Network

Traditional warehousing relies on large, centralized facilities that consolidate inventory in a few key locations, leading to longer delivery times and increased transportation costs. In contrast, micro-fulfillment centers operate within a distributed inventory network, positioning smaller hubs closer to end customers to enable faster, more cost-effective last-mile delivery.

Store-to-Door Fulfillment

Traditional warehousing utilizes large centralized facilities for bulk storage and distribution, often resulting in longer delivery times from store to door. Micro-fulfillment centers embed automated, compact storage systems within or near urban stores, enabling faster, more efficient store-to-door fulfillment by minimizing transit distances and enhancing last-mile delivery speed.

On-Demand Warehousing

On-demand warehousing revolutionizes storage solutions by offering flexible, scalable space compared to traditional warehousing's fixed, long-term leases, optimizing inventory management and reducing overhead costs. Micro-fulfillment centers enhance this by providing ultra-fast, localized order processing that meets consumer demand for rapid delivery while minimizing transportation expenses.

Micro-DC (Micro Distribution Center)

Micro-Distribution Centers (Micro-DCs) revolutionize warehousing by offering compact, highly automated facilities located close to end consumers, drastically reducing last-mile delivery times compared to traditional large-scale warehouses. These Micro-DCs leverage advanced robotics and data analytics to optimize inventory management and fulfill orders rapidly in urban environments where space and speed are critical.

Pop-Up Warehouse

Pop-up warehouses offer a flexible, temporary storage solution that complements traditional warehousing by enabling rapid deployment near high-demand areas, reducing last-mile delivery times and operational costs. Micro-fulfillment centers, integrated within pop-up warehouses, leverage automation and data analytics to optimize inventory management and increase order processing speed in urban environments.

Traditional Warehousing vs Micro-Fulfillment Infographic

industrydif.com

industrydif.com