Order picking requires workers to travel through the warehouse to locate and retrieve items, which can lead to longer picking times and increased labor costs. Goods-to-person systems bring items directly to the worker using automated technology, significantly improving efficiency and accuracy in order fulfillment. Implementing goods-to-person solutions can reduce travel time, minimize errors, and optimize space utilization within the warehouse.

Table of Comparison

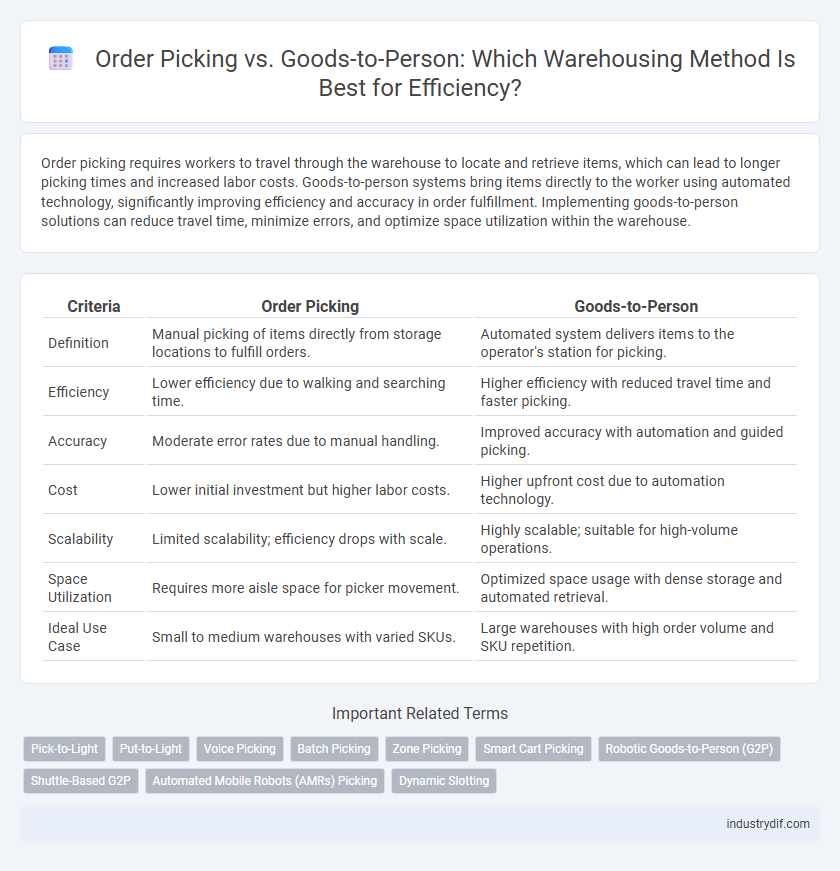

| Criteria | Order Picking | Goods-to-Person |

|---|---|---|

| Definition | Manual picking of items directly from storage locations to fulfill orders. | Automated system delivers items to the operator's station for picking. |

| Efficiency | Lower efficiency due to walking and searching time. | Higher efficiency with reduced travel time and faster picking. |

| Accuracy | Moderate error rates due to manual handling. | Improved accuracy with automation and guided picking. |

| Cost | Lower initial investment but higher labor costs. | Higher upfront cost due to automation technology. |

| Scalability | Limited scalability; efficiency drops with scale. | Highly scalable; suitable for high-volume operations. |

| Space Utilization | Requires more aisle space for picker movement. | Optimized space usage with dense storage and automated retrieval. |

| Ideal Use Case | Small to medium warehouses with varied SKUs. | Large warehouses with high order volume and SKU repetition. |

Understanding Order Picking Methods in Warehousing

Order picking methods in warehousing include traditional manual picking, batch picking, zone picking, and wave picking, each optimized for different product types and order volumes. Goods-to-person systems enhance efficiency by automating the retrieval process, delivering items directly to workers and reducing travel time. Selecting the optimal picking method depends on factors like order frequency, SKU variety, warehouse layout, and technological integration.

What Is Goods-to-Person (G2P) and How Does It Work?

Goods-to-Person (G2P) is an automated warehousing system where inventory is transported directly to the picker, improving efficiency and reducing walking time compared to traditional order picking. This technology uses robots or automated storage and retrieval systems (ASRS) to bring goods to a workstation, where operators pick items for orders. G2P increases order accuracy, speeds up fulfillment, and optimizes space utilization within the warehouse.

Traditional Order Picking: Concepts and Challenges

Traditional order picking involves manually retrieving items from storage locations, often leading to inefficiencies and high labor costs due to walking and searching time. This method faces challenges such as increased picking errors, longer order fulfillment cycles, and difficulty scaling with growing order volumes. Optimizing warehouse layout and employing technology like barcode scanning can mitigate some issues but may not fully resolve inherent limitations of manual order picking.

Speed and Accuracy: Comparing Order Picking vs Goods-to-Person

Goods-to-Person (G2P) systems significantly enhance speed and accuracy by automating the delivery of items directly to the picker, reducing travel time and minimizing human error. Traditional order picking often requires workers to navigate large warehouse spaces, increasing the likelihood of mistakes and slower fulfillment. G2P technology integrates advanced robotics and real-time data, ensuring rapid, precise selection and boosting overall warehouse efficiency.

Technology Integration in Order Fulfillment

Order picking technology integrates barcode scanning, voice picking, and automated conveyor systems to enhance accuracy and speed in fulfillment processes. Goods-to-person systems leverage robotics and AI-driven automated storage and retrieval systems (AS/RS) to deliver products directly to workers, reducing travel time and increasing efficiency. Combining these technologies results in optimized warehouse workflows, improved inventory management, and faster order processing cycles.

Labor Efficiency: Manual Picking vs Automation

Order picking in warehousing traditionally relies on manual labor, which can lead to slower fulfillment times and higher labor costs due to worker fatigue and errors. Goods-to-person systems leverage automation technology to deliver items directly to the operator, significantly increasing labor efficiency by reducing travel time and minimizing physical strain. This automation enhances order accuracy and throughput, making it a cost-effective solution for high-volume warehouses seeking to optimize labor resources.

Cost Analysis: Order Picking Versus Goods-to-Person Systems

Order picking systems often incur higher labor costs due to manual item retrieval and longer travel times, while goods-to-person systems reduce labor expenses by automating item delivery directly to workers. Investment in goods-to-person technology involves significant upfront capital but typically results in lower operational costs and increased efficiency over time. Cost analysis shows that businesses with high order volumes and SKU diversity benefit most from the reduced labor and error rates inherent in goods-to-person systems.

Scalability and Flexibility in Modern Warehousing

Order picking systems provide scalability by allowing warehouses to increase labor force and picking stations as demand grows, but may face limitations in flexibility due to manual processes. Goods-to-person technology enhances flexibility by automating item retrieval and adapting quickly to varying SKU volumes, supporting dynamic order profiles and peak demands. This automation also drives scalable operations by optimizing space utilization and labor efficiency in modern warehousing environments.

Impacts on Inventory Management and Tracking

Order Picking requires precise inventory management to ensure accurate item locations and reduce picking errors, often relying on barcode scanning and real-time tracking systems to maintain inventory accuracy. Goods-to-Person systems enhance inventory control by streamlining item retrieval through automated storage and retrieval systems, improving tracking speed and reducing human error. Both methods significantly impact inventory turnover rates and accuracy, with Goods-to-Person offering superior efficiency in high-volume environments.

Choosing the Right Solution: Key Factors for Warehouses

Order picking and goods-to-person systems differ significantly in efficiency, labor costs, and space utilization, making the right choice critical for warehouse performance. Factors such as order volume, SKU variety, and warehouse layout influence selection, with goods-to-person offering automation benefits in high-throughput environments while traditional order picking suits flexible, low-volume operations. Analyzing throughput requirements, labor availability, and technology investment helps determine the optimal solution to enhance accuracy and reduce fulfillment times.

Related Important Terms

Pick-to-Light

Pick-to-Light systems enhance order picking efficiency by using illuminated displays to guide workers directly to the correct items, significantly reducing errors and picking time compared to traditional methods. This Goods-to-Person technology optimizes warehouse workflows by minimizing travel distances and streamlining item retrieval, resulting in improved accuracy and faster fulfillment rates.

Put-to-Light

Put-to-Light technology enhances order picking accuracy and efficiency by visually guiding workers to the correct storage locations, reducing errors and speeding up the fulfillment process. Compared to traditional Goods-to-Person systems, Put-to-Light offers scalable flexibility without extensive automation costs, making it ideal for dynamic warehouse environments with varied SKU profiles.

Voice Picking

Voice picking technology enhances efficiency in both order picking and goods-to-person systems by enabling hands-free communication and real-time instructions through voice commands. This method reduces errors, accelerates picking speed, and improves worker accuracy in dynamic warehousing environments.

Batch Picking

Batch picking consolidates multiple orders into a single pick route, reducing travel time and increasing efficiency in traditional order picking systems. Goods-to-Person technology automates this process by transporting items directly to the picker, further minimizing movement and boosting throughput in high-volume warehousing environments.

Zone Picking

Zone picking segments the warehouse into specific areas where workers pick items within their designated zones, enhancing order accuracy and efficiency by reducing travel time. Compared to goods-to-person systems that automate item delivery, zone picking relies on strategic labor distribution to optimize throughput in complex order fulfillment environments.

Smart Cart Picking

Smart Cart Picking enhances order picking efficiency by automating item retrieval directly from storage locations, reducing operator walking time and errors. Integrating Goods-to-Person technology with smart carts streamlines warehouse workflows, increases throughput, and optimizes inventory accuracy in dynamic fulfillment environments.

Robotic Goods-to-Person (G2P)

Robotic Goods-to-Person (G2P) systems utilize autonomous robots to deliver inventory directly to human pickers, significantly increasing efficiency and reducing walking time compared to traditional order picking methods. This automation enhances accuracy, scalability, and throughput in warehouses, leading to faster order fulfillment and lower labor costs.

Shuttle-Based G2P

Shuttle-based Goods-to-Person (G2P) systems enhance order picking efficiency by automating item retrieval through high-speed shuttles that transport inventory directly to workstations, significantly reducing picker travel time and increasing throughput. Compared to traditional order picking methods, shuttle-based G2P optimizes space utilization and minimizes human error by integrating real-time inventory management with precise shuttle navigation.

Automated Mobile Robots (AMRs) Picking

Automated Mobile Robots (AMRs) picking systems enhance order fulfillment efficiency by autonomously navigating warehouses to transport items directly to picking stations, reducing travel time compared to traditional order picking methods. This technology accelerates picking processes, minimizes labor costs, and improves accuracy by integrating real-time inventory data with dynamic route optimization.

Dynamic Slotting

Order picking efficiency significantly improves with dynamic slotting by continuously reallocating products based on demand patterns, reducing travel time and increasing picking speed. Goods-to-person systems further enhance order fulfillment by bringing items directly to workers, maximizing productivity and minimizing errors compared to traditional manual picking methods.

Order Picking vs Goods-to-Person Infographic

industrydif.com

industrydif.com