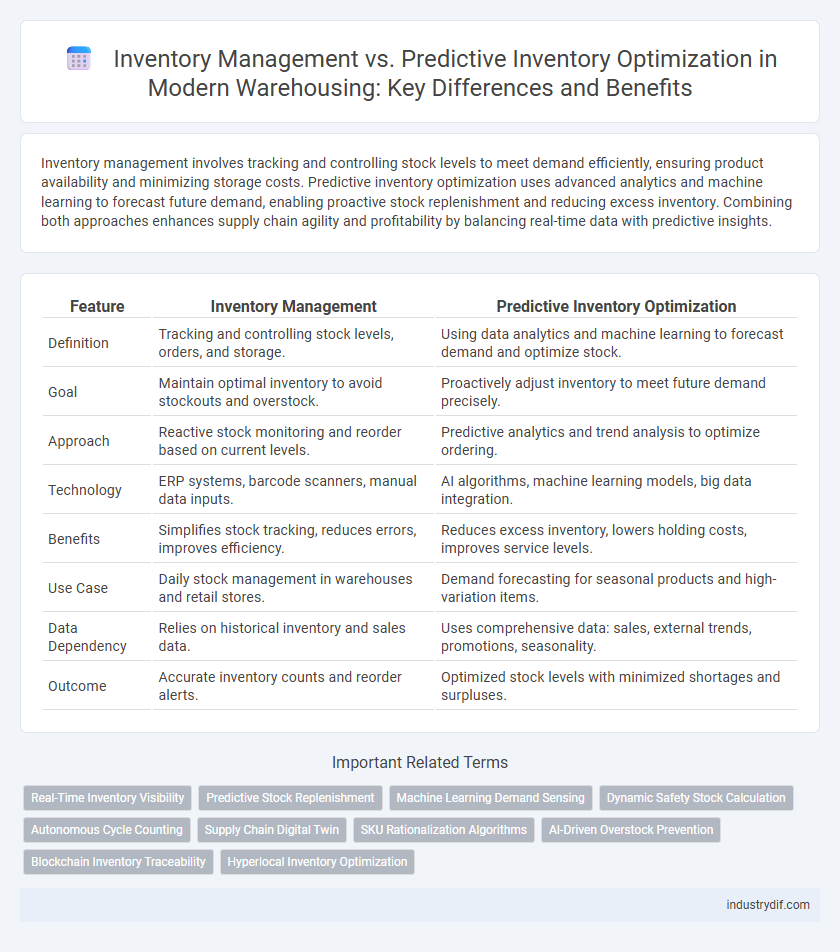

Inventory management involves tracking and controlling stock levels to meet demand efficiently, ensuring product availability and minimizing storage costs. Predictive inventory optimization uses advanced analytics and machine learning to forecast future demand, enabling proactive stock replenishment and reducing excess inventory. Combining both approaches enhances supply chain agility and profitability by balancing real-time data with predictive insights.

Table of Comparison

| Feature | Inventory Management | Predictive Inventory Optimization |

|---|---|---|

| Definition | Tracking and controlling stock levels, orders, and storage. | Using data analytics and machine learning to forecast demand and optimize stock. |

| Goal | Maintain optimal inventory to avoid stockouts and overstock. | Proactively adjust inventory to meet future demand precisely. |

| Approach | Reactive stock monitoring and reorder based on current levels. | Predictive analytics and trend analysis to optimize ordering. |

| Technology | ERP systems, barcode scanners, manual data inputs. | AI algorithms, machine learning models, big data integration. |

| Benefits | Simplifies stock tracking, reduces errors, improves efficiency. | Reduces excess inventory, lowers holding costs, improves service levels. |

| Use Case | Daily stock management in warehouses and retail stores. | Demand forecasting for seasonal products and high-variation items. |

| Data Dependency | Relies on historical inventory and sales data. | Uses comprehensive data: sales, external trends, promotions, seasonality. |

| Outcome | Accurate inventory counts and reorder alerts. | Optimized stock levels with minimized shortages and surpluses. |

Introduction to Inventory Management and Predictive Inventory Optimization

Inventory Management involves tracking stock levels, orders, sales, and deliveries to maintain optimal inventory in warehouses. Predictive Inventory Optimization uses advanced analytics and machine learning algorithms to forecast demand, reduce stockouts, and optimize reorder points. Integrating predictive modeling enhances inventory accuracy and operational efficiency compared to traditional inventory management methods.

Core Concepts: Inventory Management Explained

Inventory management involves tracking and controlling stock levels to meet demand efficiently while minimizing carrying costs and stockouts. It relies on accurate data entry, regular auditing, and reorder point formulas to maintain optimal inventory quantities. Predictive inventory optimization advances this by using data analytics and machine learning algorithms to forecast demand patterns, reducing excess inventory and improving supply chain responsiveness.

Unpacking Predictive Inventory Optimization

Predictive inventory optimization leverages advanced analytics and machine learning to forecast demand more accurately than traditional inventory management methods, enabling businesses to minimize stockouts and overstock situations. This approach integrates real-time data from sales trends, seasonal variations, and supplier performance to optimize reorder points and inventory levels dynamically. By unpacking predictive inventory optimization, warehouse operations can achieve enhanced efficiency, reduced carrying costs, and improved customer satisfaction through smarter inventory decisions.

Key Differences Between Inventory Management and Predictive Optimization

Inventory management primarily involves tracking stock levels, ordering, and storage to ensure product availability and reduce holding costs. Predictive inventory optimization leverages advanced analytics and machine learning algorithms to forecast demand accurately, optimize reorder points, and minimize stockouts and excess inventory. The key difference lies in the shift from reactive stock control to proactive, data-driven decision-making that enhances supply chain efficiency and customer satisfaction.

Benefits of Traditional Inventory Management in Warehousing

Traditional inventory management in warehousing ensures accurate stock tracking, reducing the risk of stockouts and overstock situations through systematic record-keeping and manual audits. It supports cost control by allowing warehouses to maintain optimal inventory levels based on historical demand patterns and supplier lead times. This method fosters straightforward implementation without the need for complex algorithms, making it accessible for warehouses with limited technological resources.

Advantages of Predictive Inventory Optimization for Modern Warehouses

Predictive Inventory Optimization leverages advanced algorithms and real-time data to forecast demand accurately, reducing stockouts and overstock situations in modern warehouses. This approach enhances operational efficiency by automating reorder processes and minimizing holding costs through precise inventory level adjustments. Integrating predictive analytics with warehouse management systems improves decision-making, enabling faster response times to market fluctuations and customer demands.

Data-Driven Decision Making: Role in Predictive Inventory Optimization

Data-driven decision-making plays a pivotal role in predictive inventory optimization by leveraging real-time data analytics and historical sales patterns to forecast demand accurately. Unlike traditional inventory management that relies on static reorder points, predictive models incorporate variables such as seasonality, market trends, and supply chain disruptions to optimize stock levels dynamically. This approach reduces holding costs and stockouts, enhancing overall warehouse efficiency and customer satisfaction.

Implementation Challenges: Inventory Management vs. Predictive Optimization

Inventory management systems face challenges such as manual data entry errors, lack of real-time visibility, and difficulties in demand forecasting, leading to stockouts and overstock situations. Predictive inventory optimization requires advanced data analytics, integration of multiple data sources, and skilled personnel to interpret predictive models, all of which can create significant implementation hurdles. Complexity in adopting machine learning algorithms and ensuring data quality are critical barriers that organizations must overcome to realize the full benefits of predictive optimization.

Real-World Applications and Industry Case Studies

Inventory management systems track stock levels, reorder points, and supplier lead times to maintain accurate inventory records and avoid stockouts or overstocking in warehousing operations. Predictive inventory optimization leverages machine learning algorithms and historical sales data to forecast demand more precisely, enabling dynamic stock replenishment and reducing carrying costs. Industry case studies from companies like Walmart and Amazon demonstrate how predictive models improve inventory turnover rates by up to 30% and reduce waste through real-time data analytics and automated decision-making processes.

Choosing the Right Approach for Your Warehouse Operations

Effective inventory management relies on accurate tracking and control of stock levels, ensuring timely replenishment and minimal carrying costs. Predictive inventory optimization leverages advanced analytics and machine learning to forecast demand, reduce stockouts, and optimize reorder points dynamically. Selecting the right approach depends on warehouse complexity, data availability, and the need for agility in responding to market fluctuations.

Related Important Terms

Real-Time Inventory Visibility

Real-time inventory visibility enhances inventory management by providing accurate, up-to-the-minute data on stock levels, reducing stockouts and overstock situations. Predictive inventory optimization leverages this visibility combined with advanced analytics to forecast demand, optimize stock replenishment, and improve warehouse efficiency.

Predictive Stock Replenishment

Predictive stock replenishment leverages advanced algorithms and real-time data analytics to forecast demand more accurately, reducing stockouts and excess inventory in warehouses. This approach enhances traditional inventory management by automating reorder points and optimizing stock levels based on predictive insights rather than historical data alone.

Machine Learning Demand Sensing

Inventory management relies on traditional methods of tracking stock levels and reorder points, often leading to delays and inefficiencies in supply chain operations. Predictive inventory optimization uses machine learning demand sensing techniques to analyze historical sales data and market trends, enabling real-time demand forecasting and dynamic stock replenishment that reduce stockouts and excess inventory.

Dynamic Safety Stock Calculation

Dynamic safety stock calculation in predictive inventory optimization leverages real-time demand forecasting and variability analysis to adjust stock levels proactively, minimizing stockouts and overstock risks. In contrast, traditional inventory management relies on static safety stock formulas that often fail to accommodate fluctuating market conditions and lead times, reducing overall supply chain responsiveness.

Autonomous Cycle Counting

Inventory management relies on periodic manual cycle counting, which can lead to inaccuracies and downtime, while predictive inventory optimization leverages autonomous cycle counting through AI-powered sensors and real-time data analysis to continuously monitor stock levels with higher accuracy. This autonomous approach minimizes human error, reduces operational interruptions, and enhances inventory visibility for improved warehouse efficiency.

Supply Chain Digital Twin

Inventory management relies on tracking stock levels and reordering based on historical data, while predictive inventory optimization uses advanced analytics and machine learning within a Supply Chain Digital Twin to simulate scenarios and forecast demand more accurately. This digital twin integrates real-time data across the supply chain, enabling proactive adjustments that reduce stockouts, minimize excess inventory, and enhance overall warehouse efficiency.

SKU Rationalization Algorithms

Inventory management relies on traditional stock tracking methods to monitor SKU performance, whereas predictive inventory optimization leverages advanced SKU rationalization algorithms to analyze sales patterns, demand variability, and product lifecycle data. These algorithms enable warehouses to strategically reduce redundant SKUs, improve turnover rates, and optimize storage space for higher operational efficiency.

AI-Driven Overstock Prevention

AI-driven predictive inventory optimization leverages advanced machine learning algorithms to analyze historical sales data, seasonal trends, and market fluctuations, enabling precise demand forecasting that significantly reduces overstock risks. Traditional inventory management relies on static reorder points and manual adjustments, often leading to excess stock and higher holding costs, whereas AI systems dynamically adjust inventory levels in real-time to prevent overstock and optimize warehouse efficiency.

Blockchain Inventory Traceability

Inventory management relies on accurate stock tracking and demand forecasting, whereas predictive inventory optimization leverages advanced analytics and machine learning to enhance reorder accuracy and reduce stockouts. Integrating blockchain inventory traceability in these systems ensures immutable, transparent records of product movements, improving accountability and reducing discrepancies throughout the supply chain.

Hyperlocal Inventory Optimization

Inventory management primarily tracks stock levels and reorder points to maintain supply, while predictive inventory optimization leverages real-time data and machine learning to forecast demand with precision. Hyperlocal inventory optimization refines this approach by analyzing localized buying patterns and market trends, enabling warehouses to minimize stockouts and excess holding costs tailored to specific neighborhoods or regions.

Inventory Management vs Predictive Inventory Optimization Infographic

industrydif.com

industrydif.com