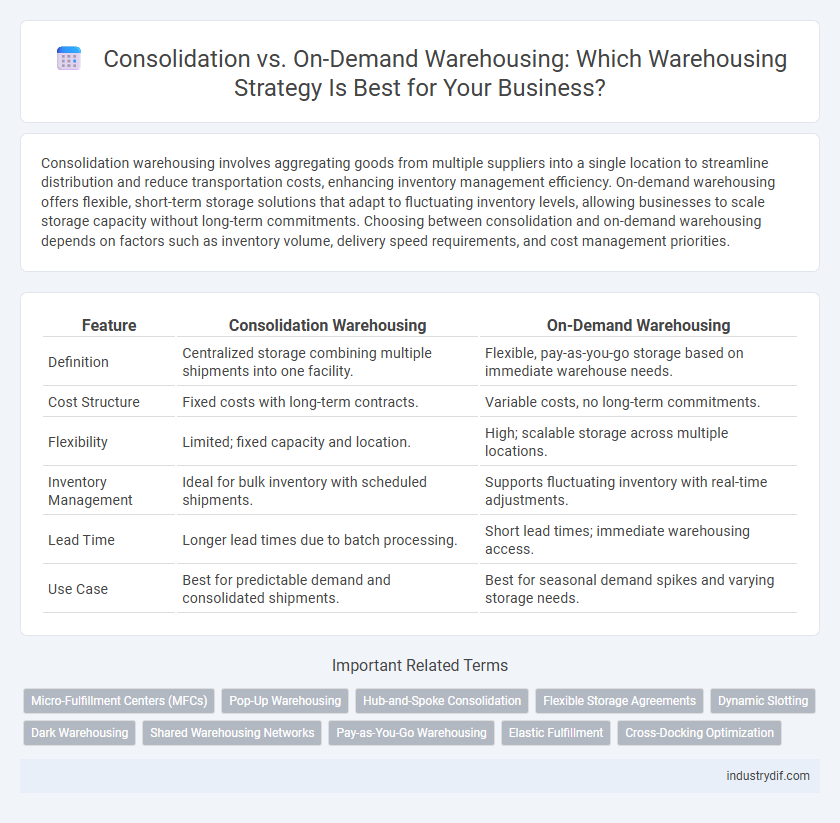

Consolidation warehousing involves aggregating goods from multiple suppliers into a single location to streamline distribution and reduce transportation costs, enhancing inventory management efficiency. On-demand warehousing offers flexible, short-term storage solutions that adapt to fluctuating inventory levels, allowing businesses to scale storage capacity without long-term commitments. Choosing between consolidation and on-demand warehousing depends on factors such as inventory volume, delivery speed requirements, and cost management priorities.

Table of Comparison

| Feature | Consolidation Warehousing | On-Demand Warehousing |

|---|---|---|

| Definition | Centralized storage combining multiple shipments into one facility. | Flexible, pay-as-you-go storage based on immediate warehouse needs. |

| Cost Structure | Fixed costs with long-term contracts. | Variable costs, no long-term commitments. |

| Flexibility | Limited; fixed capacity and location. | High; scalable storage across multiple locations. |

| Inventory Management | Ideal for bulk inventory with scheduled shipments. | Supports fluctuating inventory with real-time adjustments. |

| Lead Time | Longer lead times due to batch processing. | Short lead times; immediate warehousing access. |

| Use Case | Best for predictable demand and consolidated shipments. | Best for seasonal demand spikes and varying storage needs. |

Understanding Consolidation Warehousing

Consolidation warehousing involves aggregating goods from multiple suppliers into a single, centralized location to optimize inventory management and reduce transportation costs. This method enhances supply chain efficiency by minimizing handling, improving order accuracy, and enabling bulk shipping benefits. Warehouses using consolidation techniques typically support high-volume operations with steady demand patterns, contrasting with the flexibility-driven nature of on-demand warehousing.

What is On-Demand Warehousing?

On-demand warehousing is a flexible storage solution that allows businesses to rent warehouse space only when needed, avoiding long-term leases and fixed costs. It leverages digital platforms to match available warehouse capacity with excess inventory or seasonal demand, optimizing supply chain efficiency. This model supports scalable inventory management by providing access to storage on a short-term basis across various geographic locations.

Key Differences Between Consolidation and On-Demand Warehousing

Consolidation warehousing involves combining multiple shipments into a single load to optimize transportation costs and improve inventory management, while on-demand warehousing offers flexible, short-term storage solutions tailored to fluctuating inventory needs. Key differences include cost structure, with consolidation favoring long-term efficiency and on-demand focusing on variable expenses, and scalability, where on-demand warehousing adapts quickly to market changes versus consolidation's emphasis on planned, bulk storage. Inventory control also varies, as consolidation emphasizes synchronized stock movement across multiple suppliers, whereas on-demand warehousing provides rapid access and flexibility for seasonal or unpredictable demand.

Benefits of Consolidation Warehousing

Consolidation warehousing offers significant cost savings by reducing transportation expenses through bulk shipping and minimized handling. It enhances inventory management efficiency by centralizing stock, leading to improved order accuracy and faster fulfillment times. This approach also optimizes warehouse space utilization and reduces the frequency of shipments, resulting in lower carbon emissions and a smaller environmental footprint.

Advantages of On-Demand Warehousing

On-demand warehousing offers flexible storage capacity that adapts to fluctuating inventory levels, reducing the need for long-term leases and minimizing overhead costs. This model improves supply chain responsiveness by enabling businesses to quickly scale storage up or down based on real-time demand. It also enhances geographic reach, allowing access to multiple warehouse locations without the commitment associated with traditional consolidation warehousing.

Cost Implications: Consolidation vs On-Demand Warehousing

Consolidation warehousing reduces overall costs by pooling inventory and shipments, leading to lower transportation expenses and economies of scale in storage. On-demand warehousing, while offering flexibility and reduced fixed costs, often incurs higher per-unit expenses due to variable pricing and shorter-term agreements. Businesses must weigh the predictable cost savings of consolidation against the agility and potentially higher operational costs of on-demand solutions.

Scalability and Flexibility in Warehousing Models

Consolidation warehousing offers scalability by aggregating inventory from multiple sources into centralized locations, reducing storage costs and optimizing space utilization. On-demand warehousing provides greater flexibility, enabling businesses to quickly scale storage capacity up or down based on real-time demand without long-term commitments. These contrasting models empower companies to tailor warehousing strategies according to fluctuating supply chain needs and market conditions.

Best Use Cases for Each Warehousing Solution

Consolidation warehousing excels in scenarios requiring bulk storage and distribution, making it ideal for companies managing large inventories or seasonal fluctuations, as it streamlines shipments and reduces freight costs through volume aggregation. On-demand warehousing fits best for businesses needing flexible, short-term storage solutions, especially during peak periods or unexpected surges in demand, offering scalability without long-term commitments. Both approaches optimize supply chain efficiency by matching storage strategy to inventory patterns and cost management priorities.

Technology’s Role in Modern Warehousing

Advanced technology in modern warehousing enhances consolidation by optimizing inventory management through real-time data analytics and automated sorting systems. On-demand warehousing leverages cloud-based platforms and IoT sensors to provide scalable storage solutions with dynamic space allocation and rapid fulfillment capabilities. Integration of AI-driven forecasting and robotics improves operational efficiency, reducing costs and increasing flexibility in both consolidation and on-demand warehousing models.

Choosing the Right Warehousing Model for Your Business

Consolidation warehousing optimizes inventory by grouping products into a single location, reducing storage costs and improving order accuracy for large-scale operations. On-demand warehousing offers flexibility, allowing businesses to scale storage space based on fluctuating inventory levels and peak seasons without long-term commitments. Selecting the right warehousing model depends on your inventory volume, demand variability, and cost-efficiency priorities, ensuring optimal supply chain performance and customer satisfaction.

Related Important Terms

Micro-Fulfillment Centers (MFCs)

Micro-fulfillment centers (MFCs) excel in on-demand warehousing by enabling rapid order processing and reduced last-mile delivery times through localized, small-scale storage. Unlike consolidation warehouses that aggregate bulk inventory centrally, MFCs optimize urban fulfillment efficiency and inventory turnover by strategically placing goods closer to high-demand areas.

Pop-Up Warehousing

Pop-up warehousing leverages temporary storage facilities to meet sudden spikes in demand, offering flexibility unmatched by traditional consolidation centers that rely on fixed, long-term warehousing solutions. This approach reduces inventory holding costs and accelerates distribution by enabling businesses to scale storage capacity in real-time without committing to permanent infrastructure.

Hub-and-Spoke Consolidation

Hub-and-Spoke Consolidation in warehousing centralizes inventory at a primary distribution hub, optimizing transportation costs and improving order fulfillment efficiency by serving multiple spokes or regional warehouses. This model contrasts with On-Demand Warehousing, which relies on flexible, short-term storage solutions, prioritizing scalability and responsiveness over centralized inventory control.

Flexible Storage Agreements

Flexible storage agreements in consolidation warehousing enable businesses to optimize inventory levels by aggregating shipments from multiple suppliers, reducing overall storage costs. On-demand warehousing offers adaptability with short-term contracts that allow companies to scale space based on fluctuating market demands and seasonal peaks.

Dynamic Slotting

Dynamic slotting in consolidation warehousing optimizes inventory placement by grouping products based on demand patterns and order frequency, reducing picker travel time and improving order accuracy. On-demand warehousing leverages dynamic slotting to flexibly allocate space in real-time, enhancing responsiveness to fluctuating inventory levels and seasonal spikes without long-term commitments.

Dark Warehousing

Dark warehousing, a subset of on-demand warehousing, offers flexible, scalable storage solutions by utilizing underused warehouse space without daily inventory visibility, reducing costs compared to traditional consolidation warehouses that centralize goods for long-term storage. This approach enhances supply chain agility by enabling businesses to adapt quickly to demand fluctuations while minimizing capital investment and operational expenses.

Shared Warehousing Networks

Shared warehousing networks enable businesses to leverage consolidation by pooling storage resources, reducing costs, and enhancing inventory management efficiency compared to on-demand warehousing's flexible but often higher-priced model. Consolidation through shared networks optimizes space utilization and streamlines distribution, driving lower transportation expenses and improved supply chain visibility.

Pay-as-You-Go Warehousing

Pay-as-You-Go Warehousing offers flexibility and cost-efficiency by allowing businesses to pay only for the storage and services they use, contrasting with traditional Consolidation warehousing that often requires long-term commitments and fixed costs. This on-demand model adapts to fluctuating inventory levels, reducing overhead and improving cash flow management in dynamic supply chain environments.

Elastic Fulfillment

Elastic fulfillment leverages on-demand warehousing to dynamically scale storage and distribution capacity, optimizing inventory consolidation by matching space with real-time demand fluctuations. This approach reduces overhead costs and enhances supply chain agility by seamlessly integrating warehouses across multiple locations.

Cross-Docking Optimization

Cross-docking optimization enhances on-demand warehousing by minimizing storage time and reducing handling costs through direct transfer of goods between inbound and outbound transportation. Consolidation warehouses improve efficiency by grouping shipments to maximize load utilization, yet may increase inventory holding costs compared to dynamic cross-docking strategies.

Consolidation vs On-Demand Warehousing Infographic

industrydif.com

industrydif.com