Picking involves warehouse workers manually locating and retrieving items from shelves, which can be time-consuming and prone to errors. Goods-to-Person systems automate the retrieval process by bringing inventory directly to the worker, increasing efficiency and accuracy. This automation reduces travel time, optimizes order fulfillment, and enhances overall warehouse productivity.

Table of Comparison

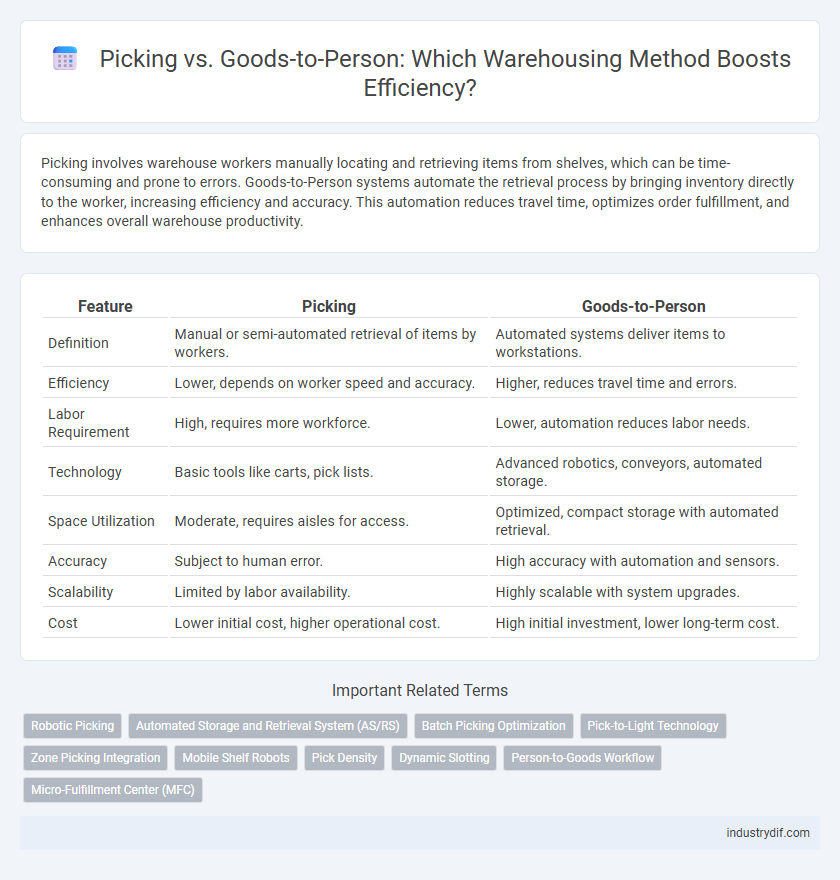

| Feature | Picking | Goods-to-Person |

|---|---|---|

| Definition | Manual or semi-automated retrieval of items by workers. | Automated systems deliver items to workstations. |

| Efficiency | Lower, depends on worker speed and accuracy. | Higher, reduces travel time and errors. |

| Labor Requirement | High, requires more workforce. | Lower, automation reduces labor needs. |

| Technology | Basic tools like carts, pick lists. | Advanced robotics, conveyors, automated storage. |

| Space Utilization | Moderate, requires aisles for access. | Optimized, compact storage with automated retrieval. |

| Accuracy | Subject to human error. | High accuracy with automation and sensors. |

| Scalability | Limited by labor availability. | Highly scalable with system upgrades. |

| Cost | Lower initial cost, higher operational cost. | High initial investment, lower long-term cost. |

Understanding Picking in Warehousing

Picking in warehousing involves manually selecting products from inventory locations to fulfill customer orders, which is a critical step in order fulfillment accuracy and efficiency. Traditional picking methods require warehouse workers to travel along aisles to gather items, impacting labor costs and throughput times. Optimizing picking processes with technologies like barcode scanning and automated data capture enhances productivity and reduces errors.

What Is Goods-to-Person (GTP) Technology?

Goods-to-Person (GTP) technology automates the retrieval of products by transporting inventory directly to warehouse operators, enhancing picking efficiency and accuracy. This system employs robotics, conveyors, and automated storage and retrieval systems (AS/RS) to minimize travel time and reduce physical strain on workers. Compared to traditional manual picking, GTP significantly increases throughput and optimizes space utilization within warehouses.

Key Differences Between Picking and Goods-to-Person

Picking involves warehouse workers manually retrieving items from storage locations, which can be time-consuming and prone to errors. Goods-to-Person systems automate this process by using robotics or automated shuttles to bring items directly to the worker, increasing accuracy and efficiency. Key differences include labor intensity, speed, error rates, and scalability, with Goods-to-Person offering significant benefits in high-volume or complex order environments.

Efficiency Comparison: Manual Picking vs. GTP

Manual picking typically involves higher labor costs and slower order fulfillment times due to workers traveling through aisles to locate items, resulting in reduced efficiency. Goods-to-Person (GTP) systems significantly increase picking speed and accuracy by automating the delivery of products directly to workers, minimizing travel time and errors. Implementing GTP technology can improve throughput by up to 50% and reduce labor requirements, making it a more efficient solution for high-volume warehouses.

Impact on Labor Costs and Workforce Management

Picking processes in warehousing often require significant manual labor, increasing labor costs and complicating workforce management due to variability in worker efficiency and order volume. Goods-to-person systems reduce labor costs by automating product delivery directly to workers, enhancing picking speed and accuracy while simplifying scheduling and reducing fatigue. This automation leads to more consistent labor utilization and lowers reliance on extensive temporary staffing during peak demand.

Accuracy and Error Rates in Order Fulfillment

Picking methods directly impact accuracy and error rates in order fulfillment, with traditional manual picking often prone to higher mistakes due to human error and mispicking. Goods-to-person systems enhance accuracy by automating item delivery to workers, reducing travel time and misplacement, which significantly lowers error rates and boosts order precision. Implementing advanced technologies like robotics and real-time inventory tracking further refines picking accuracy, ensuring consistent and reliable fulfillment processes.

Scalability: Adapting to Demand Fluctuations

Picking systems offer scalable solutions by allowing incremental workforce increases to handle demand fluctuations, but often require more physical space and manual effort. Goods-to-person systems enhance scalability through automated delivery of items directly to workers, reducing travel time and improving throughput during peak periods. This adaptability ensures optimized handling of varying order volumes while maintaining operational efficiency.

Technology Investment: Costs and ROI Considerations

Investing in goods-to-person technology requires significant upfront capital, including automated systems such as robotics and conveyor modules, but offers substantial ROI through increased picking accuracy and order throughput. Traditional picking methods incur lower initial costs yet often result in higher labor expenses and slower fulfillment rates over time. Evaluating total cost of ownership and productivity gains helps warehouses balance technology investment against operational efficiencies and long-term profitability.

Industry Applications: Which Method Suits Your Operation?

Picking methods vary across industries based on order volume, product variety, and labor costs, with traditional manual picking favored in low-volume, high-SKU operations such as specialty retail and e-commerce niches. Goods-to-Person systems excel in high-throughput environments like pharmaceuticals and electronics manufacturing, where automation enhances accuracy and reduces pick times. Selecting the appropriate method hinges on analyzing operational scale, order complexity, and investment capacity to optimize productivity and cost-efficiency.

Future Trends: The Evolution of Fulfillment Systems

Future trends in warehousing emphasize the shift from traditional picking to Goods-to-Person (G2P) systems, driven by advancements in robotics and AI for increased efficiency. G2P technology reduces travel time for workers by automatically delivering items to picking stations, enhancing accuracy and throughput. Integration with real-time inventory management and IoT devices further optimizes order fulfillment, aligning with the demands of e-commerce growth and rapid delivery expectations.

Related Important Terms

Robotic Picking

Robotic picking in warehousing enhances efficiency by automating the retrieval of items, reducing human error and improving order accuracy compared to traditional manual picking methods. The Goods-to-Person system further optimizes this process by delivering goods directly to workers or robotic arms, minimizing travel time and streamlining inventory management for faster fulfillment cycles.

Automated Storage and Retrieval System (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) enhance warehousing efficiency by minimizing manual picking errors and accelerating order fulfillment through precise robotic retrieval. Comparing picking methods, Goods-to-Person systems powered by AS/RS significantly reduce travel time and labor costs, optimizing storage density and increasing throughput in high-volume environments.

Batch Picking Optimization

Batch picking optimizes warehouse efficiency by consolidating multiple orders into single pick runs, reducing travel time and increasing throughput. Goods-to-Person systems enhance batch picking by automating item delivery directly to workers, minimizing manual labor and errors while accelerating order fulfillment.

Pick-to-Light Technology

Pick-to-Light technology enhances warehouse picking efficiency by guiding workers with illuminated displays at storage locations, significantly reducing errors and increasing speed compared to traditional manual picking. This Goods-to-Person system automates item retrieval, streamlining order fulfillment and optimizing labor productivity in high-volume operations.

Zone Picking Integration

Zone picking enhances warehouse efficiency by dividing the picking process into specific areas where workers focus on designated zones, reducing travel time and minimizing errors. Integrating goods-to-person technology within zone picking further streamlines operations by automatically delivering items to workers, increasing accuracy and boosting throughput in high-volume fulfillment environments.

Mobile Shelf Robots

Mobile shelf robots enhance Goods-to-Person systems by autonomously transporting inventory shelves directly to workers, significantly reducing travel time and increasing picking accuracy compared to traditional manual picking methods. This automation improves warehouse efficiency, scalability, and worker ergonomics, resulting in faster fulfillment cycles and lower operational costs.

Pick Density

Pick density directly impacts warehouse efficiency, with traditional picking methods often resulting in low pick density due to scattered item locations. Goods-to-Person systems significantly increase pick density by delivering multiple items to a single operator, reducing travel time and boosting throughput.

Dynamic Slotting

Dynamic slotting enhances picking efficiency by continuously reorganizing inventory locations based on real-time order patterns, reducing picker travel time compared to static methods. Goods-to-person systems leverage this adaptive inventory placement to automate item retrieval, maximizing throughput and minimizing human error in dynamic warehouse environments.

Person-to-Goods Workflow

Person-to-Goods workflow in warehousing involves workers moving directly to storage locations to pick items, enabling flexibility in handling diverse SKUs and irregular order patterns, but often resulting in higher labor costs and longer fulfillment times. Compared to Goods-to-Person systems, Person-to-Goods requires fewer automation investments and is better suited for smaller operations with lower order volumes and less predictable demand.

Micro-Fulfillment Center (MFC)

Micro-Fulfillment Centers (MFCs) optimize picking efficiency by leveraging Goods-to-Person (GTP) systems that reduce travel time and increase accuracy compared to traditional manual picking methods. The integration of automation in MFCs enables faster order fulfillment, lower labor costs, and improved inventory management through compact, scalable solutions.

Picking vs Goods-to-Person Infographic

industrydif.com

industrydif.com