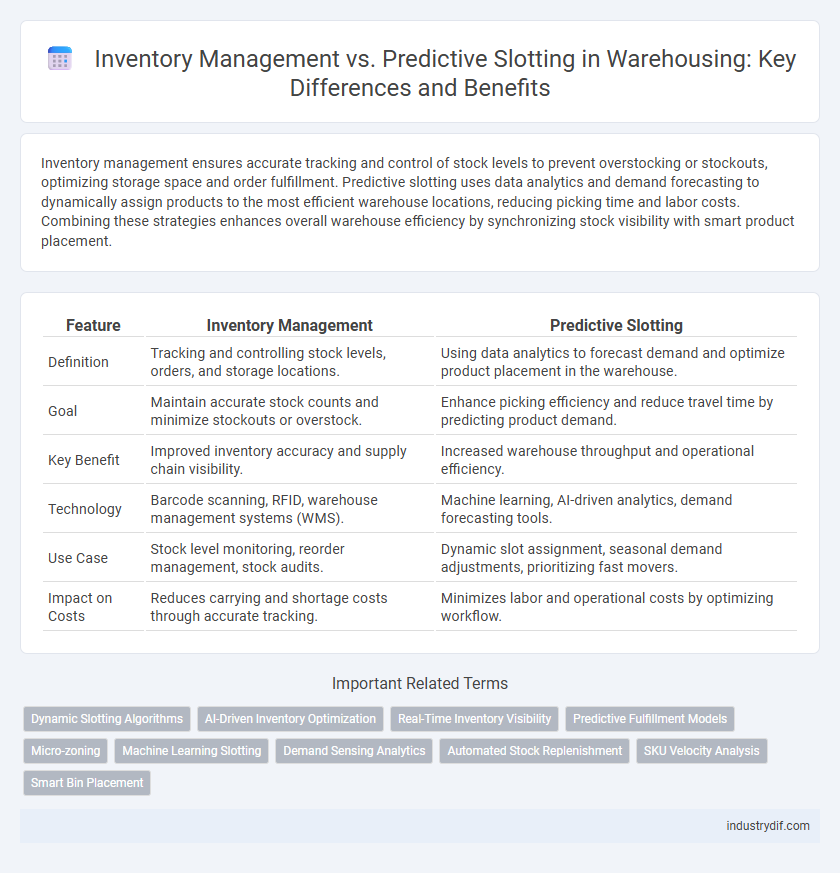

Inventory management ensures accurate tracking and control of stock levels to prevent overstocking or stockouts, optimizing storage space and order fulfillment. Predictive slotting uses data analytics and demand forecasting to dynamically assign products to the most efficient warehouse locations, reducing picking time and labor costs. Combining these strategies enhances overall warehouse efficiency by synchronizing stock visibility with smart product placement.

Table of Comparison

| Feature | Inventory Management | Predictive Slotting |

|---|---|---|

| Definition | Tracking and controlling stock levels, orders, and storage locations. | Using data analytics to forecast demand and optimize product placement in the warehouse. |

| Goal | Maintain accurate stock counts and minimize stockouts or overstock. | Enhance picking efficiency and reduce travel time by predicting product demand. |

| Key Benefit | Improved inventory accuracy and supply chain visibility. | Increased warehouse throughput and operational efficiency. |

| Technology | Barcode scanning, RFID, warehouse management systems (WMS). | Machine learning, AI-driven analytics, demand forecasting tools. |

| Use Case | Stock level monitoring, reorder management, stock audits. | Dynamic slot assignment, seasonal demand adjustments, prioritizing fast movers. |

| Impact on Costs | Reduces carrying and shortage costs through accurate tracking. | Minimizes labor and operational costs by optimizing workflow. |

Understanding Inventory Management in Warehousing

Inventory management in warehousing involves systematic tracking, organizing, and controlling stock to optimize storage efficiency and meet demand. It leverages real-time data and automated systems to maintain accurate inventory levels, reduce carrying costs, and prevent stockouts. Predictive slotting enhances this process by analyzing historical data and demand patterns to strategically position products for faster picking and improved warehouse productivity.

What Is Predictive Slotting?

Predictive slotting uses data analytics and machine learning algorithms to optimize warehouse storage by anticipating product demand patterns. Unlike traditional inventory management, which focuses on tracking stock levels and replenishment, predictive slotting strategically places high-demand items in easily accessible locations to reduce picking time and improve efficiency. This approach enhances warehouse productivity by aligning slotting decisions with forecasted order trends and seasonal fluctuations.

Key Differences Between Inventory Management and Predictive Slotting

Inventory management involves tracking stock levels, orders, and storage to maintain optimal inventory, while predictive slotting uses data analytics and demand forecasting to strategically assign products to warehouse locations. Inventory management centers on accuracy and availability of stock, whereas predictive slotting focuses on enhancing picking efficiency and reducing travel time within the warehouse. Key differences lie in their objectives: inventory management ensures stock control, predictive slotting optimizes product placement for faster fulfillment.

Benefits of Effective Inventory Management

Effective inventory management reduces carrying costs, minimizes stockouts, and improves order fulfillment rates, ensuring a balanced supply chain. Predictive slotting enhances these benefits by analyzing demand patterns to optimize product placement, accelerating picking processes and increasing warehouse efficiency. Together, they drive significant cost savings and elevate customer satisfaction through timely deliveries.

Advantages of Predictive Slotting in Modern Warehouses

Predictive slotting enhances inventory management by leveraging data analytics and machine learning to optimize product placement, reducing picking time and increasing order accuracy. Modern warehouses benefit from adaptive slotting strategies that respond to real-time demand fluctuations, improving space utilization and labor efficiency. This approach minimizes operational costs while maximizing throughput and customer satisfaction.

Impact on Warehouse Efficiency and Productivity

Inventory management ensures accurate stock levels and reduces errors, directly improving warehouse efficiency by minimizing downtime and avoiding stockouts. Predictive slotting leverages data analytics to optimize product placement, which accelerates picking processes and enhances overall productivity. Combining both strategies maximizes space utilization and streamlines operations to significantly boost warehouse performance.

Technology Driving Inventory Management and Predictive Slotting

Advanced technologies such as AI-driven analytics and IoT sensors are revolutionizing inventory management by providing real-time visibility and accurate demand forecasting. Predictive slotting leverages machine learning algorithms to optimize warehouse layout, reducing picking times and improving order fulfillment efficiency. Integrating these technologies enhances operational agility and minimizes holding costs, driving significant improvements in warehouse productivity.

Challenges in Implementing Predictive Slotting vs Inventory Management

Implementing predictive slotting faces challenges such as integrating advanced machine learning algorithms with existing warehouse management systems and handling large volumes of real-time data for accurate demand forecasting. Inventory management struggles less with technology adoption but often faces difficulties in maintaining precise stock levels due to human error and inconsistent data entry. Both methods require significant process restructuring, yet predictive slotting demands higher investments in data analytics infrastructure and skilled personnel.

Best Practices for Integrating Inventory Management and Predictive Slotting

Effective integration of inventory management and predictive slotting hinges on real-time data synchronization, enabling dynamic adjustments based on demand forecasts and stock levels. Leveraging machine learning algorithms to analyze historical sales and seasonal trends enhances slotting accuracy, reducing picking times and optimizing storage utilization. Establishing continuous feedback loops between inventory performance metrics and slotting strategies ensures adaptive refinement, driving operational efficiency and inventory turnover.

Future Trends in Warehouse Optimization

Inventory management systems are evolving towards predictive slotting techniques that leverage artificial intelligence and machine learning algorithms to forecast demand and optimize product placement. Future trends in warehouse optimization emphasize real-time data integration, automation, and predictive analytics to enhance stock accuracy, reduce picking time, and improve overall operational efficiency. Enhanced predictive slotting minimizes labor costs and maximizes storage utilization by dynamically adjusting inventory locations based on seasonal patterns and sales velocity.

Related Important Terms

Dynamic Slotting Algorithms

Dynamic slotting algorithms optimize inventory management by continuously analyzing real-time data such as order frequency, SKU velocity, and seasonal trends to adjust product placement within the warehouse. Predictive slotting leverages machine learning models to forecast demand patterns, enhancing picking efficiency and reducing travel time by proactively organizing inventory based on predicted order flows.

AI-Driven Inventory Optimization

AI-driven inventory optimization enhances warehousing efficiency by integrating predictive slotting techniques that analyze historical data and demand patterns to dynamically organize stock locations. This approach reduces picking times, minimizes stockouts, and maximizes storage utilization by anticipating inventory fluctuations and adjusting placement in real time.

Real-Time Inventory Visibility

Real-time inventory visibility enhances inventory management by providing accurate, instant data on stock levels across warehouses, reducing errors and improving order fulfillment accuracy. Predictive slotting leverages this visibility to dynamically allocate storage locations based on demand forecasts, optimizing space utilization and minimizing pick times.

Predictive Fulfillment Models

Predictive fulfillment models leverage advanced algorithms and real-time data analytics to optimize inventory placement, reducing picking times and enhancing overall warehouse efficiency. Unlike traditional inventory management, these models anticipate demand patterns and dynamically adjust slotting strategies to improve order accuracy and throughput.

Micro-zoning

Inventory management relies on tracking stock levels and locations to optimize warehousing efficiency, while predictive slotting enhances this by using data analytics to forecast demand and strategically assign products to specific micro-zones within the warehouse. Micro-zoning divides the warehouse into small, specialized areas, enabling faster picking, reduced travel time, and improved space utilization based on real-time inventory patterns and predictive insights.

Machine Learning Slotting

Machine learning slotting in warehousing optimizes inventory management by analyzing historical data and demand patterns to predict the most efficient product placement, reducing retrieval times and improving space utilization. This predictive slotting approach surpasses traditional inventory management by dynamically adjusting slot assignments to enhance order fulfillment accuracy and warehouse productivity.

Demand Sensing Analytics

Demand sensing analytics enhances inventory management by using real-time data to improve accuracy in stock levels and reduce excess inventory. Predictive slotting leverages these analytics to optimize storage locations, increasing picking efficiency and reducing labor costs.

Automated Stock Replenishment

Automated stock replenishment in inventory management leverages real-time data and predictive algorithms to efficiently maintain optimal stock levels, reducing stockouts and excess inventory. Predictive slotting enhances this process by analyzing demand patterns and product velocity, enabling dynamic adjustment of storage locations to streamline picking and improve replenishment accuracy.

SKU Velocity Analysis

SKU velocity analysis enhances inventory management by identifying fast-moving products, enabling more accurate demand forecasting and stock replenishment. Predictive slotting leverages this data to optimize warehouse layout, reducing picking time and improving order accuracy by strategically placing high-velocity SKUs in easily accessible locations.

Smart Bin Placement

Smart bin placement leverages predictive slotting algorithms to optimize inventory management by forecasting demand patterns and dynamically assigning storage locations. This approach enhances warehouse efficiency, reduces picking times, and minimizes stockouts compared to traditional inventory methods.

Inventory management vs Predictive slotting Infographic

industrydif.com

industrydif.com