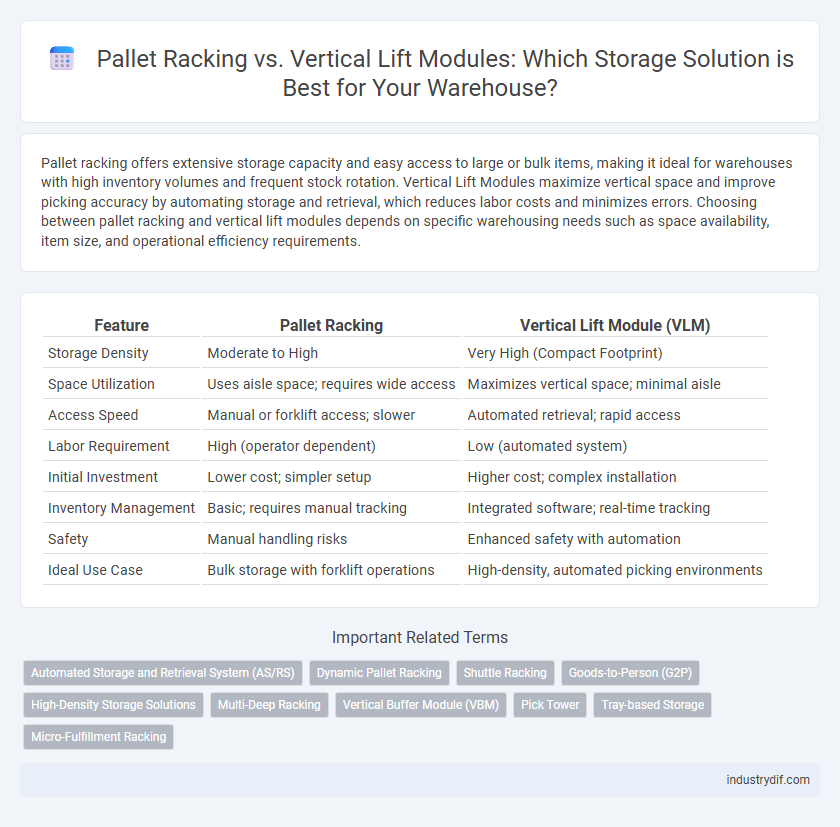

Pallet racking offers extensive storage capacity and easy access to large or bulk items, making it ideal for warehouses with high inventory volumes and frequent stock rotation. Vertical Lift Modules maximize vertical space and improve picking accuracy by automating storage and retrieval, which reduces labor costs and minimizes errors. Choosing between pallet racking and vertical lift modules depends on specific warehousing needs such as space availability, item size, and operational efficiency requirements.

Table of Comparison

| Feature | Pallet Racking | Vertical Lift Module (VLM) |

|---|---|---|

| Storage Density | Moderate to High | Very High (Compact Footprint) |

| Space Utilization | Uses aisle space; requires wide access | Maximizes vertical space; minimal aisle |

| Access Speed | Manual or forklift access; slower | Automated retrieval; rapid access |

| Labor Requirement | High (operator dependent) | Low (automated system) |

| Initial Investment | Lower cost; simpler setup | Higher cost; complex installation |

| Inventory Management | Basic; requires manual tracking | Integrated software; real-time tracking |

| Safety | Manual handling risks | Enhanced safety with automation |

| Ideal Use Case | Bulk storage with forklift operations | High-density, automated picking environments |

Introduction to Pallet Racking and Vertical Lift Modules

Pallet racking systems are essential storage solutions designed to maximize warehouse space by stacking pallets on multiple levels, enabling efficient inventory organization and easy access using forklifts. Vertical Lift Modules (VLMs) are automated storage systems that utilize vertically arranged trays within an enclosed unit, optimizing floor space and improving picking accuracy through mechanized retrieval. Both solutions enhance warehouse operational efficiency but cater to different storage density, retrieval speed, and automation levels.

Key Differences Between Pallet Racking and VLM

Pallet racking systems allow for bulk storage with easy access to individual pallets, optimizing horizontal space and manual handling efficiency in high-volume warehouses. Vertical Lift Modules (VLMs) maximize vertical storage density by automating retrieval within enclosed towers, increasing inventory accuracy and reducing footprint requirements. Pallet racking offers lower initial costs suitable for large, open storage areas, while VLMs enhance space utilization and labor productivity through mechanized storage and picking processes.

Space Utilization in Warehousing Systems

Pallet racking systems maximize horizontal storage space by allowing high-density stacking of pallets across warehouse aisles, optimizing floor utilization but requiring wide access pathways. Vertical lift modules (VLMs) enhance vertical space utilization by using automated trays in a compact, enclosed system, significantly reducing the warehouse footprint and improving aisle narrowing potential. Choosing between pallet racking and VLM depends on the warehouse layout and inventory accessibility needs, with VLMs typically enabling up to 85% space savings in height utilization compared to traditional pallet racking.

Storage Capacity Comparison

Pallet racking systems offer high-density storage ideal for large, bulky items, maximizing floor space with versatile configurations suitable for various pallet sizes. Vertical lift modules (VLMs) provide compact, automated storage, increasing vertical capacity and reducing warehouse footprint by utilizing overhead space efficiently. Comparing storage capacity, pallet racking generally supports larger volume but requires more floor area, whereas VLMs deliver higher storage density per square foot through vertical optimization and mechanized retrieval.

Accessibility and Retrieval Speed

Pallet racking provides direct access to each pallet, enabling fast manual retrieval, especially useful for bulk storage with diverse SKU sizes. Vertical Lift Modules (VLMs) enhance accessibility by automating storage and retrieval through vertical carousels, significantly reducing pick times and minimizing labor costs. VLMs optimize space vertically while ensuring high-speed, accurate order fulfillment in high-density environments.

Inventory Management Capabilities

Pallet racking systems provide flexible storage for bulkier goods and allow for easy access and visual inventory checks, enhancing manual inventory management. Vertical Lift Modules (VLMs) utilize automated, vertical storage with integrated software to optimize space and improve real-time inventory tracking accuracy. VLMs significantly reduce picking errors and increase retrieval speed, advancing overall inventory control and operational efficiency in warehousing environments.

Safety and Ergonomic Considerations

Pallet racking systems require careful load distribution and regular inspections to prevent structural failures, posing potential safety risks such as falling pallets or rack collapse. Vertical Lift Modules (VLMs) enhance safety by enclosing stored items, reducing the risk of falling objects, and incorporating automated retrieval that minimizes manual handling and operator injury. Ergonomically, VLMs improve worker comfort through adjustable access height and reduce repetitive strain, whereas pallet racking often demands reaching and climbing that can lead to musculoskeletal issues.

Cost Analysis: Initial Investment and Maintenance

Pallet racking systems require a lower initial investment compared to Vertical Lift Modules (VLMs), making them ideal for warehouses with budget constraints. However, VLMs offer reduced long-term maintenance costs due to automated inventory management and fewer manual handling errors. Evaluating total cost of ownership reveals that VLMs can provide better ROI in high-throughput environments despite higher upfront expenses.

Applicability for Various Industries

Pallet racking systems offer versatile storage solutions ideal for heavy goods and bulk inventory in industries such as manufacturing, automotive, and retail, enabling easy access and efficient space utilization. Vertical Lift Modules (VLMs) provide automated, high-density storage suited for small parts and components in sectors like electronics, pharmaceuticals, and aerospace, enhancing order accuracy and minimizing labor. Both systems optimize warehouse operations but cater to different inventory types and workflow requirements across diverse industrial applications.

Choosing the Right Solution for Your Warehouse

Pallet racking offers high storage density and easy access, ideal for warehouses handling bulky items or large inventory volumes. Vertical Lift Modules (VLMs) maximize vertical space and improve picking accuracy, making them suitable for environments with limited floor space and high SKU variety. Evaluating factors like inventory type, space constraints, and throughput requirements ensures selection of the most efficient storage solution for your warehouse operations.

Related Important Terms

Automated Storage and Retrieval System (AS/RS)

Automated Storage and Retrieval Systems (AS/RS) like Vertical Lift Modules (VLMs) offer higher storage density, improved picking accuracy, and faster access compared to traditional Pallet Racking, which relies on manual or forklift operation. VLMs optimize vertical space with automated trays and integrated software, reducing labor costs and minimizing handling errors in high-throughput warehousing environments.

Dynamic Pallet Racking

Dynamic Pallet Racking systems enhance warehouse efficiency by enabling high-density storage with gravity-driven slides that improve space utilization and reduce forklift travel time. Unlike Vertical Lift Modules, dynamic racking offers better throughput for high-volume operations by allowing easy access to multiple pallets simultaneously without advanced mechanization.

Shuttle Racking

Shuttle racking systems enhance warehouse efficiency by combining the storage density of pallet racking with automated retrieval, allowing for high throughput in narrow aisles and maximizing space utilization. Unlike traditional vertical lift modules, shuttle racking supports heavier loads and larger pallets, making it ideal for bulk storage and high-volume order fulfillment in warehouses.

Goods-to-Person (G2P)

Pallet racking systems offer high-density storage and easy accessibility for bulkier items, while Vertical Lift Modules (VLMs) optimize floor space by delivering products directly to the operator, enhancing Goods-to-Person (G2P) efficiency. VLMs reduce pick times and improve ergonomics by automating retrieval, whereas pallet racking supports larger volumes but requires more manual handling in G2P workflows.

High-Density Storage Solutions

High-density storage solutions like pallet racking maximize warehouse capacity by allowing heavy loads on multiple levels with easy forklift access, while Vertical Lift Modules (VLMs) optimize space using automated vertical lifts that increase storage density and improve picking accuracy. Comparatively, VLMs reduce aisle requirements and enhance inventory control through automated retrieval, making them ideal for high-mix, low-volume operations versus the cost-effective bulk storage efficiency of pallet racking in large-scale warehouses.

Multi-Deep Racking

Multi-Deep Racking increases storage density by allowing multiple pallets to be stored depth-wise, optimizing space usage in large warehouses but requiring specialized forklifts for access. Vertical Lift Modules (VLMs) provide automated, high-density storage with improved pick accuracy and reduced retrieval times, making them ideal for compact operations where speed and precision are critical.

Vertical Buffer Module (VBM)

Vertical Buffer Modules (VBMs) maximize warehouse storage efficiency by combining automated vertical storage with rapid item retrieval, significantly reducing aisle space compared to traditional pallet racking systems. VBMs enhance inventory accuracy and workflow automation, making them ideal for high-density storage environments requiring quick access to small-to-medium-sized loads.

Pick Tower

Pick Towers utilizing Vertical Lift Modules (VLMs) maximize storage density by automating vertical space and improving order picking accuracy, surpassing traditional pallet racking which requires more aisle space and manual handling. VLMs in Pick Towers streamline inventory retrieval through integrated software, reducing labor costs and enhancing throughput in high-demand warehousing environments.

Tray-based Storage

Pallet racking systems offer high-density storage for heavy, bulky items, while vertical lift modules (VLMs) optimize tray-based storage by maximizing vertical space and enhancing pick accuracy. Tray-based VLMs provide ergonomic access and inventory control, reducing labor costs and improving throughput compared to traditional pallet racking solutions.

Micro-Fulfillment Racking

Micro-fulfillment racking systems optimize space by combining the high-density storage of pallet racking with the automated precision of vertical lift modules, significantly reducing pick times and increasing throughput in urban warehouses. Vertical lift modules enhance efficiency by delivering items directly to operators at ergonomic heights, while pallet racking supports larger volume storage, making their integration ideal for scalable micro-fulfillment operations.

Pallet Racking vs Vertical Lift Module Infographic

industrydif.com

industrydif.com