Traditional labeling in warehousing relies on static tags that require manual updates and frequent checks, increasing labor costs and error rates. Smart shelving utilizes RFID, sensors, and IoT technology to provide real-time inventory tracking, automate stock management, and reduce human error. Implementing smart shelving enhances operational efficiency, improves accuracy, and enables dynamic inventory control compared to conventional labeling methods.

Table of Comparison

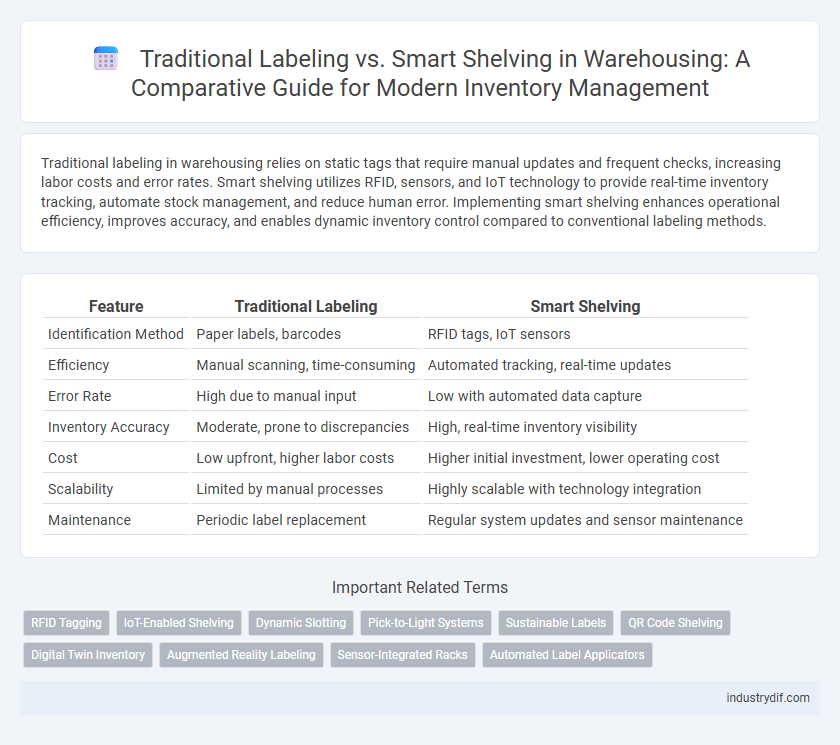

| Feature | Traditional Labeling | Smart Shelving |

|---|---|---|

| Identification Method | Paper labels, barcodes | RFID tags, IoT sensors |

| Efficiency | Manual scanning, time-consuming | Automated tracking, real-time updates |

| Error Rate | High due to manual input | Low with automated data capture |

| Inventory Accuracy | Moderate, prone to discrepancies | High, real-time inventory visibility |

| Cost | Low upfront, higher labor costs | Higher initial investment, lower operating cost |

| Scalability | Limited by manual processes | Highly scalable with technology integration |

| Maintenance | Periodic label replacement | Regular system updates and sensor maintenance |

Introduction to Warehouse Labeling Systems

Warehouse labeling systems are crucial for efficient inventory management, with traditional labeling relying on static barcode tags to identify products and locations. Smart shelving integrates IoT-enabled sensors and digital displays that update information in real-time, enhancing accuracy and reducing manual errors. Implementing smart shelving systems streamlines warehouse operations by enabling dynamic inventory tracking and faster order fulfillment.

Defining Traditional Labeling Methods

Traditional labeling methods in warehousing primarily involve the use of barcode labels, RFID tags, and manual tagging systems to identify and track inventory items. These methods rely on static labels attached to products or shelves, requiring manual scans or visual inspections for inventory management. While effective, traditional labeling often results in slower data capture and increased human error compared to advanced smart shelving technologies.

What is Smart Shelving?

Smart shelving integrates sensors and IoT technology to monitor inventory levels in real-time, enabling automated stock management and reducing human error. Unlike traditional labeling, which relies on manual scanning and static labels, smart shelving provides dynamic data updates and alerts for restocking or inventory discrepancies. This innovation enhances warehouse efficiency, accuracy, and operational visibility by streamlining inventory control processes.

Key Features of Traditional Labeling

Traditional labeling in warehousing relies on printed paper or plastic tags attached to shelves, bins, or pallets, providing essential information such as SKU numbers, product descriptions, and barcodes. These labels require manual updates and scanning, which can lead to errors and increased labor costs. Despite limited automation, traditional labeling remains a cost-effective solution for basic inventory identification and organization.

Advantages of Smart Shelving Solutions

Smart shelving solutions enhance warehousing efficiency by providing real-time inventory tracking, reducing human errors, and optimizing space utilization through automated data collection. These systems integrate with warehouse management software (WMS) to enable seamless stock monitoring and rapid identification of misplaced items. The use of IoT sensors and RFID technology in smart shelves significantly improves accuracy, speeds up order fulfillment, and lowers operational costs compared to traditional labeling methods.

Operational Efficiency: Manual vs Automated

Traditional labeling relies on manual processes for tracking inventory, which often leads to errors and slower retrieval times, reducing overall operational efficiency. Smart shelving utilizes automated sensors and RFID technology to instantly update inventory data, streamlining stock management and accelerating order fulfillment. Automated systems minimize human intervention, cutting labor costs and enhancing accuracy in warehouse operations.

Cost Implications in Implementation

Traditional labeling in warehousing relies on manual application of paper or plastic tags, which incurs ongoing costs for materials and labor. Smart shelving systems, equipped with RFID or electronic shelf labels, demand higher initial investment but reduce long-term expenses by minimizing errors and labor-intensive updates. Over time, smart shelving can lead to improved operational efficiency and lower total cost of ownership compared to traditional labeling methods.

Scalability and Flexibility Concerns

Traditional labeling systems in warehousing often struggle with scalability due to the manual effort required to update or replace labels as inventory changes, leading to increased labor costs and potential errors. Smart shelving integrates IoT sensors and real-time data analytics, offering greater flexibility by automatically adjusting to inventory variations and enabling seamless scalability across multiple warehouse locations. This technology reduces downtime and enhances accuracy, catering efficiently to dynamic supply chain demands.

Data Integration and Real-Time Tracking

Smart shelving systems revolutionize warehousing by integrating data from IoT sensors and RFID tags, enabling real-time inventory tracking and seamless data synchronization across warehouse management systems (WMS). Traditional labeling relies on static barcodes and manual scanning, which limits data integration and delays updates, increasing the risk of stock discrepancies. Real-time tracking via smart shelving enhances operational accuracy, reduces labor costs, and facilitates dynamic inventory management by providing up-to-the-minute visibility into stock levels and location.

Future Trends in Warehouse Identification

Future trends in warehouse identification are shifting from traditional labeling methods such as barcodes and QR codes toward smart shelving solutions integrated with IoT sensors and RFID technology. Smart shelving enhances real-time inventory tracking accuracy, reduces manual labor, and optimizes space utilization through automated data collection and analytics. Adoption of AI-driven systems in smart shelving enables predictive maintenance and dynamic asset management, revolutionizing warehouse efficiency and identification precision.

Related Important Terms

RFID Tagging

RFID tagging in smart shelving systems enables real-time inventory tracking and rapid item identification, significantly reducing errors and labor costs compared to traditional barcode labeling methods. This advanced technology enhances warehouse efficiency by automating stock management and improving data accuracy through wireless communication between RFID tags and readers.

IoT-Enabled Shelving

IoT-enabled smart shelving transforms traditional labeling by integrating real-time inventory tracking and automated replenishment alerts using embedded sensors and connectivity, significantly enhancing warehouse efficiency and accuracy. This technology reduces human error, streamlines stock management, and enables predictive analytics for proactive inventory control in modern warehousing operations.

Dynamic Slotting

Dynamic slotting in smart shelving systems optimizes warehouse efficiency by continuously analyzing inventory data to assign products to the most accessible locations, reducing retrieval times compared to traditional labeling methods that rely on static, fixed slots. This real-time adaptability improves space utilization and order accuracy, significantly enhancing overall supply chain responsiveness.

Pick-to-Light Systems

Pick-to-light systems in smart shelving significantly outperform traditional labeling by reducing picking errors and improving order accuracy through real-time visual guidance directly on the shelves. This advanced technology minimizes labor time and enhances warehouse efficiency by integrating with inventory management systems for seamless item tracking and faster fulfillment.

Sustainable Labels

Traditional labeling relies on disposable paper tags that contribute to waste and require frequent replacement, increasing environmental impact in warehousing operations. Smart shelving integrates reusable electronic labels powered by energy-efficient e-ink technology, significantly reducing material waste and supporting sustainable inventory management.

QR Code Shelving

QR code shelving revolutionizes traditional labeling by enabling quick digital access to inventory data, reducing human errors, and streamlining warehouse operations. Unlike static labels, QR codes integrate with warehouse management systems to provide real-time updates, enhancing accuracy and efficiency in stock tracking and retrieval.

Digital Twin Inventory

Traditional labeling in warehousing relies on static, physical labels that require manual updates, often leading to errors and inefficiencies in inventory management. Smart shelving, integrated with Digital Twin Inventory technology, provides real-time, accurate digital replicas of physical stock, enhancing visibility, automation, and decision-making in supply chain operations.

Augmented Reality Labeling

Augmented Reality (AR) labeling in warehousing enhances inventory management by overlaying digital information onto physical shelves, enabling real-time data access and reducing errors compared to traditional barcode labels. Smart shelving systems integrated with AR improve picking accuracy and operational efficiency by guiding workers with visual cues, streamlining stock replenishment and order fulfillment processes.

Sensor-Integrated Racks

Sensor-integrated racks in smart shelving systems enable real-time inventory tracking and automated stock management, significantly reducing human errors common in traditional labeling methods. These advanced sensors provide accurate item detection and location data, optimizing warehouse space utilization and enhancing operational efficiency.

Automated Label Applicators

Automated label applicators enhance warehousing accuracy by quickly applying precise labels, reducing human error compared to traditional labeling methods that rely on manual effort. Smart shelving integrates these applicators with digital inventory systems, enabling real-time tracking and efficient stock management.

Traditional Labeling vs Smart Shelving Infographic

industrydif.com

industrydif.com