Barcode scanning in warehousing offers fast and accurate item identification through simple line-of-sight scanning, making it ideal for high-volume environments. Vision picking leverages advanced image recognition and augmented reality to provide workers with real-time visual guidance, enhancing picking accuracy and reducing errors. Choosing between barcode scanning and vision picking depends on the complexity of inventory management and the need for automation and worker efficiency.

Table of Comparison

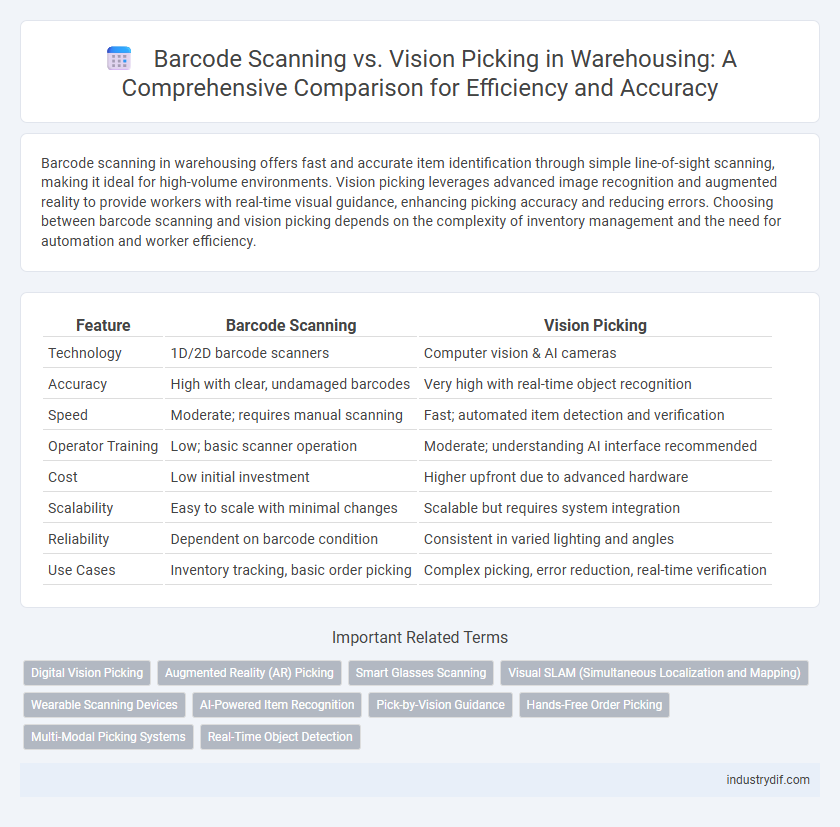

| Feature | Barcode Scanning | Vision Picking |

|---|---|---|

| Technology | 1D/2D barcode scanners | Computer vision & AI cameras |

| Accuracy | High with clear, undamaged barcodes | Very high with real-time object recognition |

| Speed | Moderate; requires manual scanning | Fast; automated item detection and verification |

| Operator Training | Low; basic scanner operation | Moderate; understanding AI interface recommended |

| Cost | Low initial investment | Higher upfront due to advanced hardware |

| Scalability | Easy to scale with minimal changes | Scalable but requires system integration |

| Reliability | Dependent on barcode condition | Consistent in varied lighting and angles |

| Use Cases | Inventory tracking, basic order picking | Complex picking, error reduction, real-time verification |

Introduction to Barcode Scanning and Vision Picking

Barcode scanning uses laser or imaging technology to quickly read encoded product information, enabling accurate item identification and inventory management in warehouses. Vision picking employs advanced computer vision systems and augmented reality to guide workers visually through picking tasks, improving accuracy and efficiency by overlaying digital instructions directly onto the physical environment. Both technologies enhance warehouse operations by reducing errors and speeding up order fulfillment processes.

How Barcode Scanning Works in Warehousing

Barcode scanning in warehousing operates by using handheld or fixed scanners to emit laser beams or infrared light, which read the unique patterns of bars representing product information. The scanned data is instantly transmitted to warehouse management systems (WMS) for real-time inventory tracking, order verification, and streamlined picking processes. This technology enhances accuracy and efficiency by minimizing manual input errors and speeding up the identification and movement of goods within storage facilities.

Vision Picking Technology Explained

Vision picking technology transforms warehousing by using wearable devices like smart glasses to guide workers through picking tasks with real-time visual instructions. This system reduces errors and increases speed by overlaying digital picking information directly in the worker's field of view, enhancing accuracy and efficiency compared to traditional barcode scanning. Integrating augmented reality with warehouse management software, vision picking streamlines operations and supports complex order fulfillment in high-volume environments.

Key Differences: Barcode Scanning vs Vision Picking

Barcode scanning relies on laser or image-based technology to read printed codes for item identification, ensuring quick and accurate inventory tracking. Vision picking uses augmented reality (AR) glasses or cameras to display pick information directly in the worker's line of sight, enhancing real-time decision-making and reducing errors. The key difference lies in barcode scanning's dependency on physical labels versus vision picking's hands-free, contextual guidance for improved operational efficiency.

Efficiency Comparison: Warehouse Operations

Barcode scanning offers rapid item identification with high accuracy, reducing pick times and minimizing errors in high-volume warehouse operations. Vision picking systems utilize augmented reality and computer vision to provide real-time visual guidance, enhancing worker productivity by streamlining complex picking tasks and reducing cognitive load. Efficiency gains from vision picking are significant in dynamic, multi-SKU environments, whereas barcode scanning remains optimal for standardized and repetitive inventory processes.

Accuracy and Error Reduction

Barcode scanning offers high accuracy by quickly capturing specific data from coded labels, minimizing human error during item identification in warehousing. Vision picking enhances error reduction through real-time visual guidance and object recognition, supporting complex sorting tasks and reducing mispicks. Combining barcode scanning with vision picking technologies delivers a robust solution for optimizing picking accuracy and minimizing warehouse operational errors.

Cost Implications for Implementation

Barcode scanning systems offer lower initial costs and easier integration due to mature technology and minimal hardware requirements, making them cost-effective for small to medium warehouses. Vision picking involves higher upfront expenses related to advanced cameras, software, and training but can improve accuracy and efficiency, potentially reducing labor costs over time. Choosing between the two depends on balancing immediate budget constraints with long-term operational savings and scalability needs.

Integration with Warehouse Management Systems

Barcode scanning seamlessly integrates with Warehouse Management Systems (WMS) by providing accurate, real-time data capture that enhances inventory tracking and order fulfillment efficiency. Vision picking systems leverage advanced cameras and software to interpret visual information, enabling dynamic task assignment and hands-free order processing within the WMS environment. Both technologies improve operational workflows but differ in integration complexity, with barcode scanning offering straightforward WMS connectivity while vision picking requires more sophisticated software calibration and system interoperability.

Training and Adoption Challenges

Barcode scanning requires minimal training and has high adoption rates due to its straightforward scanning process, while vision picking demands more extensive operator training to interpret visual cues and interface with complex augmented reality systems. The learning curve associated with vision picking can slow implementation across warehouse teams and increase initial resistance. Organizations must invest in comprehensive training programs to overcome adoption challenges and ensure seamless integration of vision picking technology.

Future Trends in Picking Technologies

Future trends in warehouse picking technologies emphasize the integration of advanced vision picking systems that leverage AI-driven image recognition to enhance accuracy and speed compared to traditional barcode scanning. Vision picking reduces dependency on manual scanning and enables seamless identification of multiple SKUs in a single glance, boosting operational efficiency. As automation and machine learning evolve, warehouses adopting vision-based picking will experience significant improvements in throughput and error reduction.

Related Important Terms

Digital Vision Picking

Digital Vision Picking enhances warehouse efficiency by using smart glasses and augmented reality to provide real-time visual guidance, reducing errors and increasing picking speed. Unlike traditional barcode scanning, this technology streamlines workflows with hands-free operation and dynamic item identification, enabling higher throughput and improved accuracy in order fulfillment.

Augmented Reality (AR) Picking

Augmented Reality (AR) Picking enhances warehouse efficiency by overlaying digital information onto the physical environment, enabling workers to visually identify and select items with increased accuracy compared to traditional barcode scanning. This technology reduces errors and speeds up order fulfillment by providing real-time guidance and hands-free operation, transforming vision picking through immersive AR interfaces.

Smart Glasses Scanning

Smart glasses scanning in warehousing leverages augmented reality to enhance picking accuracy and efficiency by overlaying barcode information directly in the operator's field of view, reducing errors and speeding up workflow. Compared to traditional barcode scanning, vision picking with smart glasses enables hands-free operation, real-time data access, and seamless integration with warehouse management systems, optimizing inventory control and order fulfillment processes.

Visual SLAM (Simultaneous Localization and Mapping)

Visual SLAM enhances vision picking in warehousing by enabling real-time 3D mapping and precise localization of items without relying solely on barcode scanning, increasing accuracy and efficiency in inventory management. Integrating Visual SLAM technology reduces scanning errors and accelerates order fulfillment through automated, camera-based item recognition and spatial awareness.

Wearable Scanning Devices

Wearable scanning devices enhance warehouse efficiency by enabling hands-free barcode scanning, reducing errors and increasing picking speed compared to traditional vision picking systems reliant on manual item recognition. Integrating wearable scanners with warehouse management systems improves real-time inventory tracking, streamlines order fulfillment, and minimizes operator fatigue in high-volume picking environments.

AI-Powered Item Recognition

AI-powered item recognition in warehousing leverages deep learning algorithms to enhance accuracy and speed by identifying products through barcode scanning and advanced vision picking systems. Vision picking integrates AI-driven cameras to recognize items without reliance on barcodes, improving efficiency in environments with damaged or missing labels.

Pick-by-Vision Guidance

Pick-by-vision guidance in warehousing leverages augmented reality glasses to display real-time picking instructions directly in the worker's field of view, significantly improving accuracy and speed compared to traditional barcode scanning methods. This technology reduces manual errors, enhances productivity by enabling hands-free operation, and integrates seamlessly with warehouse management systems for optimized inventory control.

Hands-Free Order Picking

Hands-free order picking enhances warehouse efficiency by utilizing vision picking systems that allow workers to scan barcodes without handheld devices, reducing errors and increasing speed. Compared to traditional barcode scanning methods, vision picking leverages wearable technology and augmented reality to streamline picking processes, improve accuracy, and enable real-time inventory updates.

Multi-Modal Picking Systems

Multi-modal picking systems integrate barcode scanning and vision picking to enhance accuracy and efficiency in warehousing operations by leveraging barcode data for precise item identification and computer vision for contextual understanding of product placement. This combination reduces picking errors, accelerates order fulfillment, and optimizes inventory management through real-time data analytics and automated verification processes.

Real-Time Object Detection

Real-time object detection in warehousing enhances inventory accuracy by using barcode scanning for precise item identification and vision picking for dynamic, hands-free order fulfillment. Integrating these technologies improves operational efficiency, reduces errors, and accelerates the picking process in fast-paced warehouse environments.

Barcode Scanning vs Vision Picking Infographic

industrydif.com

industrydif.com