Manual picking relies on traditional methods such as paper lists or handheld devices, which can slow down order fulfillment and lead to higher error rates. Voice picking enhances accuracy and efficiency by guiding workers through verbal instructions, allowing hands-free operation and faster item retrieval. Implementing voice picking technology often results in improved productivity and reduced training time compared to manual picking processes.

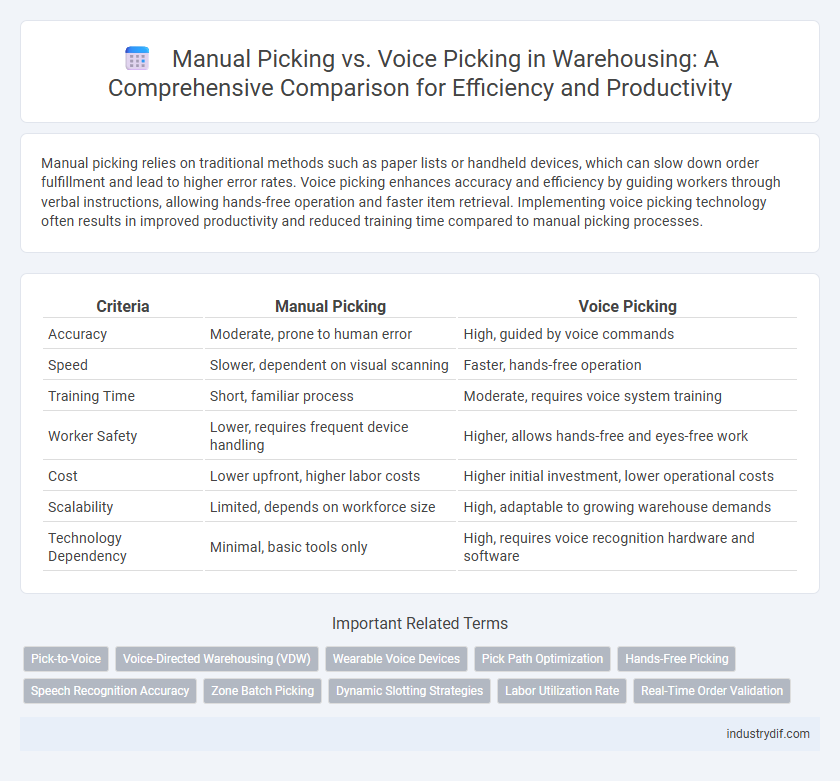

Table of Comparison

| Criteria | Manual Picking | Voice Picking |

|---|---|---|

| Accuracy | Moderate, prone to human error | High, guided by voice commands |

| Speed | Slower, dependent on visual scanning | Faster, hands-free operation |

| Training Time | Short, familiar process | Moderate, requires voice system training |

| Worker Safety | Lower, requires frequent device handling | Higher, allows hands-free and eyes-free work |

| Cost | Lower upfront, higher labor costs | Higher initial investment, lower operational costs |

| Scalability | Limited, depends on workforce size | High, adaptable to growing warehouse demands |

| Technology Dependency | Minimal, basic tools only | High, requires voice recognition hardware and software |

Introduction to Manual Picking and Voice Picking

Manual picking involves warehouse workers selecting items by visually locating products and physically retrieving them, often using paper lists or handheld devices for order management. Voice picking uses voice-directed technology where workers receive instructions through headsets, allowing hands-free operation and reducing errors by guiding pickers with auditory commands. Both methods aim to improve order accuracy and efficiency, with voice picking offering enhanced productivity through real-time verbal instructions.

Key Differences Between Manual and Voice Picking

Manual picking relies on paper-based instructions or handheld scanners to guide warehouse workers, leading to slower and error-prone processes. Voice picking uses voice-directed technology that allows pickers to receive instructions and confirm tasks hands-free, enhancing accuracy and efficiency. Key differences include increased speed, reduced errors, and improved worker safety and productivity with voice picking compared to manual methods.

Technology Overview: How Voice Picking Works

Voice picking technology uses wearable devices such as headsets and microphones to guide warehouse workers through picking tasks using verbal instructions, improving accuracy and efficiency. The system integrates with warehouse management software (WMS) to provide real-time updates and confirmation via voice commands, reducing the need for handheld devices or paper lists. This hands-free approach enhances worker productivity by allowing faster item retrieval and minimizing errors compared to traditional manual picking methods.

Labor Efficiency in Manual vs Voice Picking

Manual picking relies heavily on workers' visual and physical efforts, often resulting in slower task completion and higher error rates. Voice picking technology enhances labor efficiency by enabling hands-free operation, reducing search time, and improving accuracy through real-time verbal instructions. Warehouses implementing voice picking report up to 25% increase in picking speed and a significant reduction in labor fatigue compared to manual methods.

Accuracy and Error Rates Comparison

Manual picking relies on visual and paper-based instructions, which increases the likelihood of human errors, leading to accuracy rates typically around 85-90%. Voice picking systems guide workers through audio commands, improving accuracy levels to 98-99% by reducing misreads and mispicks. Studies show voice picking reduces error rates by up to 50% compared to manual methods, enhancing warehouse productivity and order accuracy.

Training Time and Worker Adaptability

Manual picking requires longer training time due to reliance on physical documentation and route memorization, often leading to slower worker adaptability in dynamic warehouse environments. Voice picking systems reduce training time by providing real-time audio instructions, enabling workers to adapt quickly and maintain higher accuracy. Consequently, voice picking enhances operational efficiency by minimizing onboarding periods and supporting workforce flexibility.

Implementation Costs and ROI

Manual picking involves lower upfront implementation costs compared to voice picking systems, which require investment in specialized hardware and software. However, voice picking delivers higher accuracy and faster processing speeds, contributing to a quicker return on investment (ROI) by reducing errors and labor costs. Warehouses adopting voice picking often experience improved order fulfillment rates, making the initial expense justified over time through increased operational efficiency.

Safety Considerations in Picking Methods

Manual picking in warehousing often increases safety risks due to reliance on visual cues and physical handling, leading to higher chances of accidents such as slips, trips, and ergonomic injuries. Voice picking systems enhance safety by enabling hands-free and eyes-free operations, reducing distractions and allowing workers to maintain better spatial awareness. Implementing voice-directed technology can significantly lower workplace injuries and improve compliance with occupational safety standards in warehouse environments.

Scalability for Warehouse Operations

Manual picking limits scalability in warehouse operations due to slower throughput and higher error rates, which constrain growth during peak demand. Voice picking enhances scalability by providing hands-free, real-time guidance, increasing picking speed and accuracy across large and dynamic inventories. Integrating voice picking systems streamlines workflows and supports rapid adaptation to fluctuating order volumes, maximizing operational efficiency.

Future Trends: Automation and Picking Solutions

Future trends in warehousing emphasize the integration of automation technologies with picking solutions to enhance efficiency and accuracy. Voice picking systems are increasingly combined with automated guided vehicles (AGVs) and robotic arms to streamline manual operations while reducing errors. Advancements in AI-driven voice recognition and real-time data analytics further enable adaptive picking workflows, optimizing inventory management and labor productivity.

Related Important Terms

Pick-to-Voice

Pick-to-Voice technology enhances warehouse efficiency by enabling workers to receive and confirm picking instructions verbally, reducing errors and increasing pick rates compared to manual picking methods. This hands-free system improves accuracy and productivity by guiding pickers through voice commands, minimizing reliance on handheld devices and paper-based lists.

Voice-Directed Warehousing (VDW)

Voice-directed warehousing (VDW) enhances picking accuracy and efficiency by guiding workers through verbal instructions, reducing errors compared to manual picking methods reliant on paper or handheld devices. Studies show VDW implementation can boost order fulfillment speed by up to 20% while improving worker safety through hands-free operation.

Wearable Voice Devices

Wearable voice devices in warehouse picking improve accuracy and efficiency by enabling hands-free, eyes-free operation, reducing picking errors compared to traditional manual methods. By integrating real-time voice instructions, these devices accelerate order fulfillment and enhance worker productivity in fast-paced logistics environments.

Pick Path Optimization

Manual picking relies heavily on worker experience and visual cues which can lead to inefficient pick path optimization and longer retrieval times. Voice picking systems utilize real-time algorithms and audio directions to dynamically optimize pick paths, significantly improving accuracy and reducing travel distance in warehouses.

Hands-Free Picking

Voice picking enables hands-free operation in warehouses, increasing worker productivity and accuracy compared to manual picking methods that require constant handling of paper or devices. This technology reduces errors, speeds up order fulfillment, and enhances safety by allowing workers to maintain focus on tasks without interrupting their workflow.

Speech Recognition Accuracy

Manual picking relies heavily on visual confirmation, increasing the risk of errors in high-volume warehouses, while voice picking leverages advanced speech recognition technology that can achieve accuracy rates above 95% in noisy environments. Improved speech recognition accuracy reduces picking errors and enhances worker productivity by enabling hands-free, eyes-free operations in complex warehousing settings.

Zone Batch Picking

Zone batch picking enhances efficiency by assigning pickers to specific warehouse zones, reducing travel time and improving order accuracy during manual picking processes. Voice picking further optimizes zone batch picking by enabling hands-free, real-time communication, which accelerates picking speed and minimizes errors.

Dynamic Slotting Strategies

Dynamic slotting strategies significantly enhance warehouse efficiency by optimizing the allocation of inventory locations based on real-time demand and picking methods, with manual picking requiring more rigid slotting due to slower operator movement and voice picking benefiting from flexible slot adjustments that reduce travel time and error rates. Implementing voice picking integrated with adaptive slotting algorithms leads to increased throughput, improved accuracy, and reduced labor costs compared to traditional manual picking systems.

Labor Utilization Rate

Manual picking typically results in lower labor utilization rates due to increased time spent on locating and handling items, whereas voice picking systems enhance labor efficiency by enabling hands-free, real-time instructions that reduce picking errors and speed up order fulfillment. Studies show voice picking can improve labor utilization rates by up to 20%, optimizing workforce productivity in busy warehouse environments.

Real-Time Order Validation

Manual picking often leads to delays and errors in real-time order validation due to reliance on paper-based systems or handheld devices with limited feedback. Voice picking technology enhances accuracy and efficiency by providing instant verbal confirmation and updates, ensuring orders are validated immediately as items are picked.

Manual Picking vs Voice Picking Infographic

industrydif.com

industrydif.com