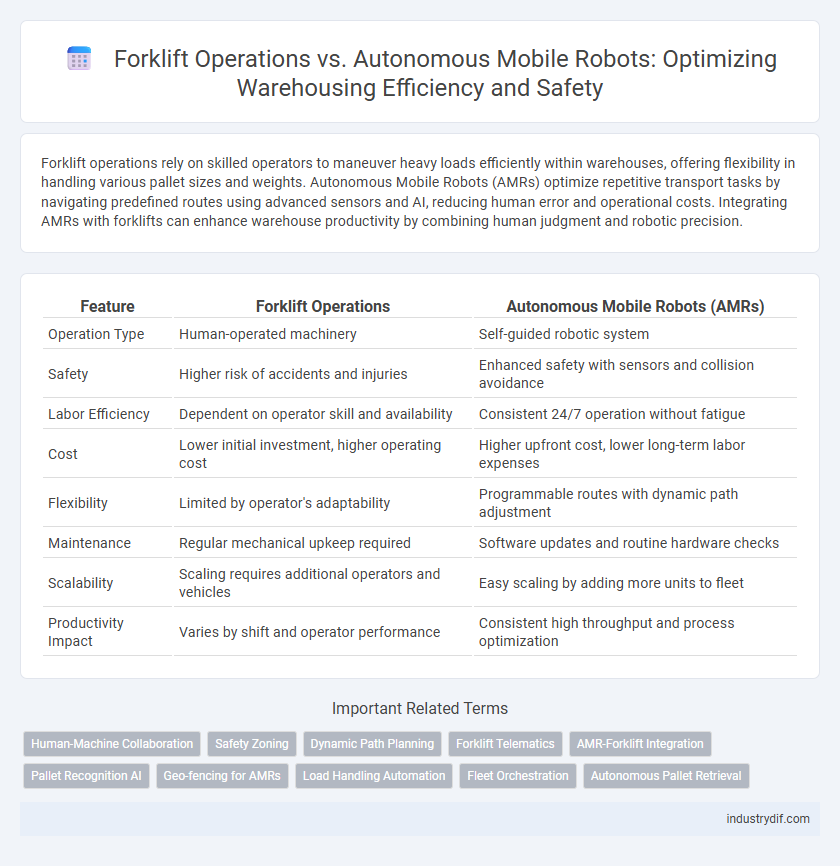

Forklift operations rely on skilled operators to maneuver heavy loads efficiently within warehouses, offering flexibility in handling various pallet sizes and weights. Autonomous Mobile Robots (AMRs) optimize repetitive transport tasks by navigating predefined routes using advanced sensors and AI, reducing human error and operational costs. Integrating AMRs with forklifts can enhance warehouse productivity by combining human judgment and robotic precision.

Table of Comparison

| Feature | Forklift Operations | Autonomous Mobile Robots (AMRs) |

|---|---|---|

| Operation Type | Human-operated machinery | Self-guided robotic system |

| Safety | Higher risk of accidents and injuries | Enhanced safety with sensors and collision avoidance |

| Labor Efficiency | Dependent on operator skill and availability | Consistent 24/7 operation without fatigue |

| Cost | Lower initial investment, higher operating cost | Higher upfront cost, lower long-term labor expenses |

| Flexibility | Limited by operator's adaptability | Programmable routes with dynamic path adjustment |

| Maintenance | Regular mechanical upkeep required | Software updates and routine hardware checks |

| Scalability | Scaling requires additional operators and vehicles | Easy scaling by adding more units to fleet |

| Productivity Impact | Varies by shift and operator performance | Consistent high throughput and process optimization |

Introduction to Forklift Operations and Autonomous Mobile Robots

Forklift operations involve manually operated vehicles designed to lift, move, and stack heavy materials in warehouses, providing reliable handling for a variety of palletized goods. Autonomous Mobile Robots (AMRs) utilize advanced sensors, machine learning, and navigation algorithms to independently transport items, optimize pathways, and reduce human labor in warehouse logistics. Comparing these technologies highlights the shift from traditional manual forklift use to innovative, automated solutions enhancing efficiency and safety in warehousing environments.

Key Differences Between Forklifts and AMRs in Warehousing

Forklift operations rely on manual control and skilled operators to move heavy loads, ensuring precision in tight spaces and complex tasks, whereas Autonomous Mobile Robots (AMRs) utilize advanced sensors and AI to navigate warehouses independently, optimizing efficiency and reducing labor costs. Forklifts excel in lifting heavy pallets and heavy-duty tasks, while AMRs are designed for repetitive material transport and inventory movement without human intervention. Safety protocols differ as forklifts require operator training and pose higher accident risks, whereas AMRs enhance workplace safety by minimizing human error and collisions.

Safety Considerations: Forklifts vs AMRs

Forklift operations pose significant safety risks due to manual human control, increasing the likelihood of accidents such as collisions, tipping, and injuries in busy warehouse environments. Autonomous Mobile Robots (AMRs) enhance safety by utilizing advanced sensors, real-time navigation, and obstacle detection systems to minimize human error and reduce workplace incidents. Implementing AMRs in warehouses can lead to a safer work environment by lowering the frequency of accidents associated with traditional forklift operations.

Efficiency and Productivity Comparison

Forklift operations offer high load capacity and versatile handling for heavy goods but require skilled operators and face downtime due to breaks and safety protocols. Autonomous Mobile Robots (AMRs) enhance warehouse efficiency by operating continuously, reducing labor costs, and optimizing route planning through advanced sensors and AI. Studies show AMRs can increase productivity by up to 30% by minimizing bottlenecks and improving material flow, while forklifts remain essential for bulky item transport.

Costs and ROI: Traditional vs Autonomous Solutions

Forklift operations typically incur higher costs due to operator wages, training, and maintenance, whereas Autonomous Mobile Robots (AMRs) offer lower ongoing expenses and reduced human error-related costs. ROI for traditional forklifts is limited by labor efficiency and safety risks, while AMRs deliver faster payback through enhanced productivity, scalability, and 24/7 operational capabilities. Implementing autonomous solutions results in significant cost savings and improved return on investment by optimizing warehouse workflows and minimizing downtime.

Training and Skill Requirements

Forklift operations demand extensive hands-on training and certification, emphasizing operator safety, maneuvering skills, and equipment maintenance knowledge. Autonomous mobile robots (AMRs) require personnel skilled in programming, system monitoring, and troubleshooting software-related issues, reducing the need for traditional manual operation expertise. Transitioning to AMRs shifts the workforce focus from physical operation to technical proficiency in robotics and automation systems.

Flexibility and Scalability in Warehouse Operations

Forklift operations offer high flexibility in navigating complex warehouse layouts and handling diverse load types but require skilled operators and face limitations in scalability due to labor costs and safety constraints. Autonomous Mobile Robots (AMRs) provide scalable solutions through automated, programmable routing and seamless integration with warehouse management systems, enabling rapid adaptation to changing inventory demands and layouts without additional labor. Combining AMRs with manual forklift tasks can optimize flexibility while enhancing overall warehouse scalability and operational efficiency.

Maintenance and Downtime Factors

Forklift operations require regular mechanical inspections and scheduled maintenance to prevent breakdowns, leading to extended downtime during repairs. Autonomous Mobile Robots (AMRs) feature predictive maintenance capabilities using sensor data to minimize unexpected failures and optimize uptime. While forklifts demand higher labor costs for maintenance, AMRs reduce downtime and operational interruptions through automated diagnostics and remote monitoring.

Integration with Warehouse Management Systems

Forklift operations typically require manual input and coordination with Warehouse Management Systems (WMS) through barcode scanners or RFID readers, which can limit real-time data accuracy and operational efficiency. Autonomous Mobile Robots (AMRs) seamlessly integrate with WMS via advanced software interfaces, enabling dynamic task allocation, real-time inventory updates, and optimized routing within the warehouse. This integration enhances overall workflow automation, reduces human error, and improves inventory visibility for smarter warehouse management.

Future Trends in Material Handling Technologies

Future trends in material handling technologies emphasize the integration of Autonomous Mobile Robots (AMRs) alongside traditional forklift operations to enhance warehouse efficiency and safety. AMRs offer precise navigation, real-time data integration, and scalable automation that reduce human error and operational costs. The convergence of AI-driven robotics and IoT sensors is set to revolutionize inventory management, enabling seamless collaboration between forklifts and AMRs in dynamic warehousing environments.

Related Important Terms

Human-Machine Collaboration

Forklift operations combined with autonomous mobile robots (AMRs) enhance warehouse efficiency through seamless human-machine collaboration, where operators manage complex tasks while AMRs handle repetitive material transport. This synergy reduces manual labor, minimizes safety risks, and increases throughput by optimizing task allocation based on each system's strengths.

Safety Zoning

Forklift operations require strict safety zoning protocols to prevent accidents in high-traffic warehouse environments, including designated pathways and speed limits. Autonomous Mobile Robots use advanced sensors and geofencing technology to dynamically enforce safety zones, reducing human error and improving overall warehouse safety compliance.

Dynamic Path Planning

Forklift operations in warehousing rely on manual or programmed routes, often limiting flexibility in dynamic environments, whereas autonomous mobile robots utilize advanced dynamic path planning algorithms to continuously adapt routes in real-time, enhancing efficiency and reducing collisions. This capability enables AMRs to navigate complex warehouse layouts with varying obstacles and traffic, optimizing throughput and operational safety.

Forklift Telematics

Forklift telematics systems provide real-time data on vehicle location, operator behavior, and maintenance needs, enhancing safety and operational efficiency in warehousing. Compared to autonomous mobile robots, forklifts equipped with telematics offer precise control and detailed analytics, enabling better fleet management and reducing downtime.

AMR-Forklift Integration

Integrating Autonomous Mobile Robots (AMRs) with traditional forklift operations enhances warehouse efficiency by combining the precision and automation of AMRs with the heavy-lifting capabilities of forklifts. This synergy improves material handling workflows, reduces labor costs, and optimizes space utilization in warehouse environments.

Pallet Recognition AI

Forklift operations utilize manual control and traditional sensors for pallet handling, while autonomous mobile robots (AMRs) integrate advanced Pallet Recognition AI to enhance accuracy and efficiency in identifying and transporting pallets. Pallet Recognition AI leverages machine learning algorithms and computer vision, reducing errors and optimizing warehouse workflow compared to conventional forklift methods.

Geo-fencing for AMRs

Geo-fencing technology enhances Autonomous Mobile Robots (AMRs) by creating virtual boundaries within warehouses to optimize navigation, improve safety, and prevent operational conflicts with human-driven forklift operations. This dynamic spatial control enables AMRs to operate efficiently in designated zones, reducing downtime and increasing overall warehouse productivity.

Load Handling Automation

Forklift operations in warehousing rely on skilled operators to manage heavy loads efficiently, but autonomous mobile robots (AMRs) enhance load handling automation by integrating advanced sensors and AI for precise, continuous material transport with minimal human intervention. AMRs optimize throughput and safety by navigating complex warehouse environments autonomously, reducing operational costs and human error compared to traditional forklift systems.

Fleet Orchestration

Fleet orchestration in forklift operations relies heavily on manual scheduling and operator coordination, often leading to inefficiencies and higher labor costs. In contrast, autonomous mobile robots utilize advanced fleet management systems with real-time data analytics and AI-driven task allocation to optimize routes, reduce downtime, and enhance overall warehouse productivity.

Autonomous Pallet Retrieval

Autonomous pallet retrieval using Autonomous Mobile Robots (AMRs) enhances warehouse efficiency by precisely navigating aisles and retrieving pallets without human intervention, reducing labor costs and minimizing errors. Compared to traditional forklift operations, AMRs offer improved safety, scalability, and adaptability in dynamic warehouse environments, optimizing inventory management and throughput.

Forklift Operations vs Autonomous Mobile Robots Infographic

industrydif.com

industrydif.com