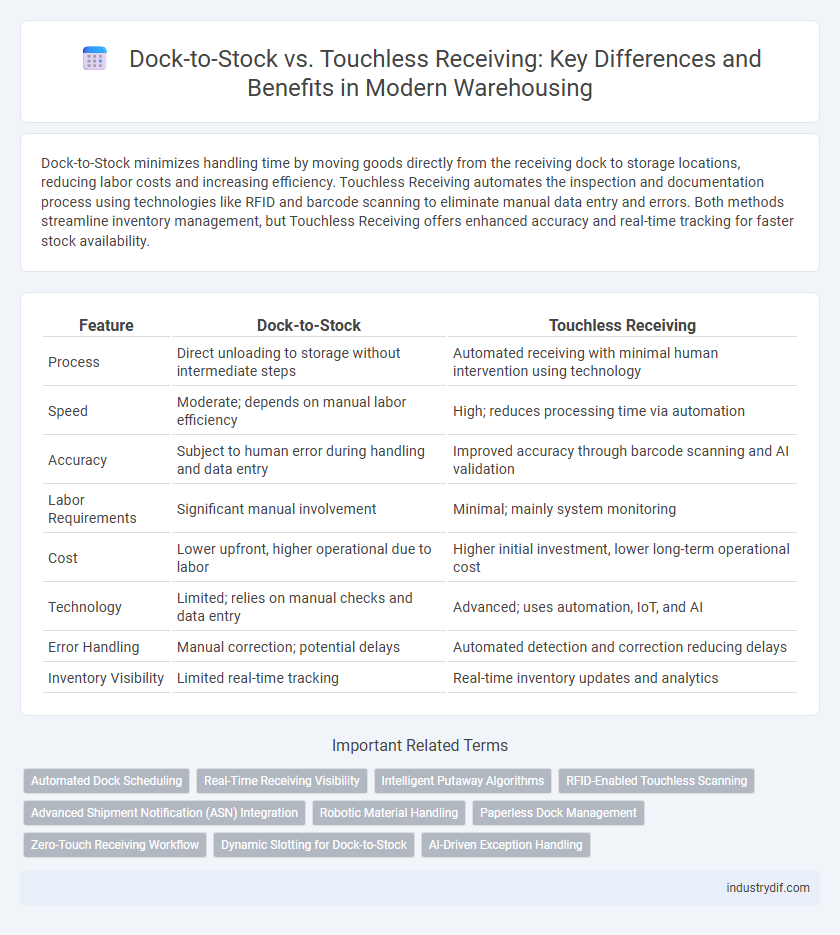

Dock-to-Stock minimizes handling time by moving goods directly from the receiving dock to storage locations, reducing labor costs and increasing efficiency. Touchless Receiving automates the inspection and documentation process using technologies like RFID and barcode scanning to eliminate manual data entry and errors. Both methods streamline inventory management, but Touchless Receiving offers enhanced accuracy and real-time tracking for faster stock availability.

Table of Comparison

| Feature | Dock-to-Stock | Touchless Receiving |

|---|---|---|

| Process | Direct unloading to storage without intermediate steps | Automated receiving with minimal human intervention using technology |

| Speed | Moderate; depends on manual labor efficiency | High; reduces processing time via automation |

| Accuracy | Subject to human error during handling and data entry | Improved accuracy through barcode scanning and AI validation |

| Labor Requirements | Significant manual involvement | Minimal; mainly system monitoring |

| Cost | Lower upfront, higher operational due to labor | Higher initial investment, lower long-term operational cost |

| Technology | Limited; relies on manual checks and data entry | Advanced; uses automation, IoT, and AI |

| Error Handling | Manual correction; potential delays | Automated detection and correction reducing delays |

| Inventory Visibility | Limited real-time tracking | Real-time inventory updates and analytics |

Introduction to Dock-to-Stock and Touchless Receiving

Dock-to-Stock and Touchless Receiving streamline warehouse operations by reducing manual handling and expediting inventory processing. Dock-to-Stock eliminates storage staging by moving products directly from the receiving dock to storage locations, enhancing efficiency and accuracy. Touchless Receiving leverages automation technologies such as barcode scanning and RFID to capture shipment data without human intervention, minimizing errors and accelerating throughput.

Key Differences Between Dock-to-Stock and Touchless Receiving

Dock-to-Stock streamlines warehouse operations by moving inventory directly from the loading dock to storage locations, minimizing handling time and reducing labor costs. Touchless Receiving leverages advanced technologies like barcode scanning and RFID to automate the verification and data capture processes, eliminating manual input and errors. The key difference lies in Dock-to-Stock optimizing physical flow and storage efficiency, while Touchless Receiving enhances data accuracy and operational speed through automation.

The Evolution of Receiving Processes in Warehousing

Dock-to-Stock and Touchless Receiving represent significant advancements in warehousing efficiency, reducing manual handling and accelerating inventory turnover. Dock-to-Stock streamlines the receiving process by moving goods directly from the dock to storage, minimizing steps and labor costs. Touchless Receiving utilizes automation and IoT technology to capture data electronically, eliminating paper-based processes and enhancing real-time inventory accuracy.

How Dock-to-Stock Works

Dock-to-Stock streamlines inventory management by moving goods directly from the receiving dock to storage without intermediate handling steps. This process employs barcode scanning or RFID technology at the dock to verify and update inventory records in real time, reducing labor costs and minimizing errors. Efficient coordination between receiving, inspection, and storage teams ensures rapid turnaround and maximized warehouse throughput.

Understanding Touchless Receiving Technology

Touchless Receiving technology streamlines the warehousing process by automating the verification and sorting of inbound goods, reducing manual labor and errors. It utilizes advanced sensors, RFID scanning, and AI-driven data capture to instantly record product information and update inventory systems in real-time. This technology enhances operational efficiency, accelerates dock-to-stock cycles, and improves accuracy by minimizing physical handling during receiving.

Efficiency and Accuracy: A Comparative Analysis

Dock-to-Stock streamlines warehouse operations by directly transferring goods from the receiving dock to storage locations, reducing handling time and minimizing inventory errors. Touchless Receiving employs automated scanning and data capture technology to eliminate manual input, significantly enhancing accuracy and speeding up the check-in process. Comparing both, dock-to-stock excels in operational efficiency through reduced physical handling, while touchless receiving ensures superior accuracy by leveraging real-time data integration.

Impact on Warehouse Labor and Resource Allocation

Dock-to-Stock processes reduce warehouse labor intensity by minimizing handling steps and accelerating product flow directly from receiving docks to storage, optimizing resource allocation. Touchless Receiving leverages automation and advanced scanning technologies to eliminate manual data entry, significantly decreasing labor costs while reallocating workforce to higher-value tasks. Both strategies enhance efficiency, but touchless receiving offers greater potential for labor savings and improved accuracy in inventory management.

Integration with Warehouse Management Systems (WMS)

Dock-to-Stock significantly streamlines inventory processes by enabling real-time data capture directly linked to Warehouse Management Systems (WMS), reducing delays and errors in stock updates. Touchless Receiving enhances this integration by automating the entire receiving workflow through technologies like RFID and IoT sensors, facilitating instant reconciliation with WMS without manual intervention. Both methodologies leverage seamless WMS connectivity to optimize inventory accuracy, operational efficiency, and supply chain visibility in modern warehousing environments.

Implementation Challenges and Considerations

Implementing dock-to-stock requires accurate inventory systems and real-time data synchronization to minimize errors and delays in receiving processes. Touchless receiving demands advanced technologies like RFID and IoT integration, which often involve significant upfront costs and staff training to ensure seamless operation. Both approaches necessitate careful evaluation of warehouse layout and workflow to align technology capabilities with operational goals and regulatory compliance.

Future Trends in Warehouse Receiving Solutions

Dock-to-Stock and Touchless Receiving are revolutionizing warehouse receiving solutions by minimizing handling times and enhancing inventory accuracy through automation and real-time data integration. Future trends emphasize the use of AI-powered sensors, IoT connectivity, and blockchain technology to streamline dock-to-stock processes, reduce manual touchpoints, and improve traceability across supply chains. These advancements aim to increase operational efficiency, reduce labor costs, and support scalable, contactless warehouse environments essential for next-generation logistics.

Related Important Terms

Automated Dock Scheduling

Automated dock scheduling streamlines dock-to-stock processes by precisely allocating loading bay times, minimizing wait times and accelerating inventory turnover. Touchless receiving enhances this efficiency by integrating real-time data capture and automated verification, reducing manual handling and expediting stock placement.

Real-Time Receiving Visibility

Real-time receiving visibility enhances Dock-to-Stock processes by allowing immediate inventory updates as goods arrive, significantly reducing handling time and errors. Touchless Receiving optimizes this further by automating data capture and verification, ensuring accuracy and accelerating the flow of products directly into storage without manual intervention.

Intelligent Putaway Algorithms

Intelligent putaway algorithms optimize Dock-to-Stock processes by automating inventory placement directly from receiving docks, reducing handling times and minimizing errors. Touchless Receiving leverages these algorithms further to enable seamless data capture and real-time location assignment, enhancing warehouse efficiency and accuracy.

RFID-Enabled Touchless Scanning

RFID-enabled touchless scanning enhances dock-to-stock processes by drastically reducing manual handling and accelerating inventory updates, leading to increased accuracy and faster cycle times. This technology minimizes human error and labor costs, enabling real-time visibility and seamless integration with warehouse management systems (WMS) for optimized stock replenishment.

Advanced Shipment Notification (ASN) Integration

Dock-to-Stock processes rely heavily on Advanced Shipment Notification (ASN) integration to streamline inventory updates by automatically matching incoming goods with pre-received data, significantly reducing docking time and labor costs. Touchless Receiving takes ASN integration further by enabling fully automated verification and put-away workflows, eliminating manual scanning and accelerating warehouse throughput for just-in-time inventory management.

Robotic Material Handling

Robotic material handling streamlines the dock-to-stock process by automating unloading, sorting, and stocking, significantly reducing manual touchpoints and cycle times. Touchless receiving leverages advanced robotics and AI-driven sensors to enable real-time inventory updates and error-free pallet scanning, enhancing accuracy and operational efficiency in warehousing.

Paperless Dock Management

Dock-to-Stock accelerates inventory flow by directly moving goods from the dock to storage without intermediate handling, reducing processing times and errors. Touchless Receiving leverages paperless dock management with RFID and barcode scanning to automate data capture, minimizing manual input and enhancing real-time inventory accuracy.

Zero-Touch Receiving Workflow

Zero-Touch Receiving Workflow eliminates manual handling by automating barcode scanning and data entry at the dock, reducing errors and accelerating inventory updates. Compared to traditional Dock-to-Stock processes, it streamlines warehouse operations by minimizing human intervention and enabling real-time visibility into stock levels.

Dynamic Slotting for Dock-to-Stock

Dynamic slotting in Dock-to-Stock optimizes warehouse efficiency by directly moving inbound goods from the dock to their designated storage locations, minimizing handling time and reducing labor costs. This approach contrasts with Touchless Receiving, which leverages automation for data capture but may still require intermediate staging, whereas Dynamic Slotting streamlines inventory flow and enhances space utilization through real-time slot adjustments.

AI-Driven Exception Handling

AI-driven exception handling in dock-to-stock processes minimizes manual intervention by automatically identifying and resolving discrepancies during unloading, accelerating inventory updates and reducing errors. Touchless receiving leverages advanced sensors and AI to enable seamless data capture and exception management, enhancing accuracy and operational efficiency in real-time warehouse operations.

Dock-to-Stock vs Touchless Receiving Infographic

industrydif.com

industrydif.com