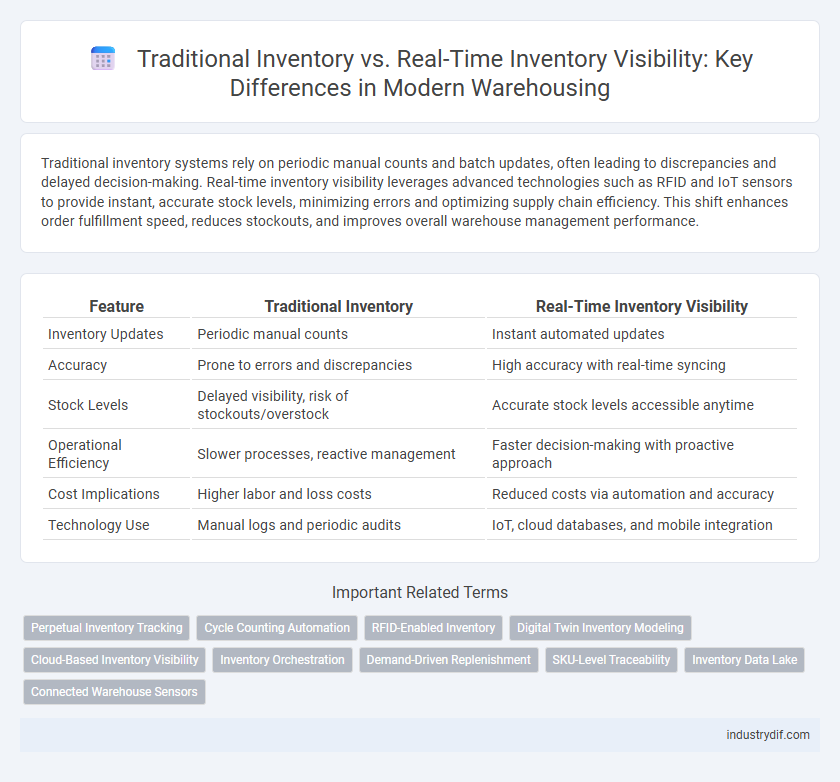

Traditional inventory systems rely on periodic manual counts and batch updates, often leading to discrepancies and delayed decision-making. Real-time inventory visibility leverages advanced technologies such as RFID and IoT sensors to provide instant, accurate stock levels, minimizing errors and optimizing supply chain efficiency. This shift enhances order fulfillment speed, reduces stockouts, and improves overall warehouse management performance.

Table of Comparison

| Feature | Traditional Inventory | Real-Time Inventory Visibility |

|---|---|---|

| Inventory Updates | Periodic manual counts | Instant automated updates |

| Accuracy | Prone to errors and discrepancies | High accuracy with real-time syncing |

| Stock Levels | Delayed visibility, risk of stockouts/overstock | Accurate stock levels accessible anytime |

| Operational Efficiency | Slower processes, reactive management | Faster decision-making with proactive approach |

| Cost Implications | Higher labor and loss costs | Reduced costs via automation and accuracy |

| Technology Use | Manual logs and periodic audits | IoT, cloud databases, and mobile integration |

Understanding Traditional Inventory Management

Traditional inventory management relies on periodic stock counts and manual record-keeping, which often leads to discrepancies and delayed updates in inventory status. This method limits the ability to respond swiftly to demand fluctuations and increases the risk of stockouts or overstocking. Warehouses using traditional systems may face inefficiencies due to lack of real-time data integration and slower decision-making processes.

Defining Real-Time Inventory Visibility

Real-time inventory visibility is a dynamic system that provides continuous, up-to-the-minute tracking of stock levels across all warehouse locations, enabling precise demand forecasting and efficient replenishment. Unlike traditional inventory methods that rely on periodic manual counts or batch updates, real-time systems integrate IoT sensors, barcode scanners, and automated data capture to deliver instantaneous accuracy. This level of visibility minimizes stockouts and overstock situations by offering actionable insights into inventory movements and availability at any given moment.

Key Differences Between Traditional and Real-Time Systems

Traditional inventory systems rely on periodic manual counts and batch updates, often leading to inaccurate stock levels and delayed decision-making. Real-time inventory visibility leverages IoT sensors, barcode scanners, and integrated software to provide continuous, accurate tracking of stock movement and availability. This immediate data access improves order accuracy, enhances supply chain responsiveness, and reduces stockouts and overstock situations.

Impact on Order Accuracy and Fulfillment

Traditional inventory systems rely on periodic stock counts, often leading to discrepancies and delayed updates that reduce order accuracy and slow fulfillment processes. Real-time inventory visibility leverages advanced tracking technologies such as RFID and IoT sensors, enabling precise stock levels and immediate status updates that significantly improve order accuracy. Enhanced inventory transparency in real-time systems accelerates fulfillment speed by minimizing errors and ensuring timely product availability for dispatch.

Technology Driving Real-Time Inventory Visibility

Traditional inventory systems rely on periodic manual counts and batch updates, leading to delayed data and potential stock discrepancies. Real-time inventory visibility leverages technologies such as RFID, IoT sensors, and cloud-based management platforms to provide continuous, accurate tracking of stock levels and movements. These advancements enable warehouses to optimize order fulfillment, reduce overstock and stockouts, and improve overall operational efficiency through instantaneous data access.

Cost Implications: Traditional vs Real-Time

Traditional inventory systems often incur higher costs due to manual tracking, increased labor, and delayed stock replenishment that can lead to overstocking or stockouts. Real-time inventory visibility reduces holding costs and minimizes lost sales by providing accurate, up-to-the-minute data for efficient decision-making and demand forecasting. Investing in real-time technology ultimately lowers operational expenses and enhances inventory turnover rates in warehousing operations.

Risk Assessment: Stockouts and Overstocks

Traditional inventory systems rely heavily on periodic manual counts, increasing the risk of stockouts and overstocks due to delayed data updates. Real-time inventory visibility leverages automated tracking technologies like RFID and IoT sensors, enabling immediate risk assessment and proactive stock adjustments. This continuous data flow minimizes stock discrepancies and optimizes inventory levels, reducing both lost sales and excess carrying costs.

Scalability and Growth Potential

Traditional inventory systems rely on periodic updates and manual counts, limiting scalability and hindering rapid response to market changes. Real-time inventory visibility leverages automated data capture and analytics, enabling seamless scalability and supporting dynamic growth by providing instant, accurate stock levels. This continuous insight enhances decision-making, reduces stockouts, and optimizes warehouse operations for expanding businesses.

Integration with Supply Chain Partners

Traditional inventory systems rely on periodic updates and manual data entry, limiting real-time accuracy and causing potential delays in sharing information with supply chain partners. Real-time inventory visibility integrates seamlessly with supply chain partners through automated data exchange, enabling instant updates and improved synchronization across the entire supply chain network. This integration enhances demand forecasting, reduces stockouts, and optimizes replenishment processes for more efficient warehouse operations.

Future Trends in Inventory Management Systems

Future trends in inventory management systems emphasize real-time inventory visibility, leveraging IoT sensors and AI-driven analytics to enhance accuracy and reduce stockouts. Traditional inventory methods relying on periodic manual counts face limitations in responsiveness and data accuracy, hindering supply chain agility. Integration of cloud-based platforms and blockchain technology promises improved transparency, automated replenishment, and predictive demand forecasting for next-generation warehouse management.

Related Important Terms

Perpetual Inventory Tracking

Traditional inventory systems rely on periodic stock counts that can lead to discrepancies and delayed updates, whereas real-time inventory visibility utilizes perpetual inventory tracking to continuously monitor stock levels through automated data capture technologies like RFID and barcode scanning. This approach enhances accuracy, reduces stockouts and overstock situations, and improves decision-making by providing up-to-date inventory data across the supply chain.

Cycle Counting Automation

Cycle counting automation significantly enhances inventory accuracy by enabling continuous, real-time inventory visibility, reducing reliance on manual, traditional inventory audits prone to errors and stock discrepancies. Integrating automated cycle counting systems in warehousing streamlines stock reconciliation processes, minimizes downtime, and improves order fulfillment efficiency through updated inventory data.

RFID-Enabled Inventory

RFID-enabled inventory systems transform traditional warehousing by providing real-time visibility that drastically reduces stock discrepancies and enhances accuracy. This technology enables instant tracking of goods, improving order fulfillment speed and minimizing losses compared to periodic manual counts in traditional inventory methods.

Digital Twin Inventory Modeling

Traditional inventory systems rely on periodic updates and manual counts, leading to delayed insights and potential stock discrepancies. Real-time inventory visibility leverages digital twin inventory modeling to create accurate, dynamic replicas of warehouse stock, enabling instant tracking, predictive analytics, and optimized inventory management.

Cloud-Based Inventory Visibility

Cloud-based inventory visibility enables warehouses to access real-time data on stock levels, reducing errors and improving order accuracy compared to traditional inventory systems reliant on periodic updates. This technology enhances supply chain responsiveness by integrating data from multiple locations instantly, facilitating better demand forecasting and inventory optimization.

Inventory Orchestration

Traditional inventory systems rely on periodic updates that can lead to discrepancies and delayed response in supply chain management, whereas real-time inventory visibility leverages IoT sensors and integrated software to provide accurate, instant data for efficient inventory orchestration. This shift enables dynamic stock allocation, reduces stockouts, and optimizes warehouse operations by synchronizing demand signals with inventory levels in real-time.

Demand-Driven Replenishment

Traditional inventory relies on periodic stock counts, causing delays in demand-driven replenishment and potential stockouts or overstock situations. Real-time inventory visibility leverages IoT sensors and cloud-based systems to continuously update stock levels, enabling precise, demand-driven replenishment that reduces carrying costs and improves order fulfillment accuracy.

SKU-Level Traceability

Traditional inventory systems often rely on periodic stock counts and batch updates, which can lead to inaccuracies and delays in SKU-level traceability. Real-time inventory visibility leverages RFID, IoT sensors, and integrated software platforms to provide continuous, precise tracking of SKU movement, enabling immediate decision-making and reducing stockouts or overstock situations.

Inventory Data Lake

Traditional inventory systems rely on batch updates and periodic stock counts, resulting in delayed and often inaccurate inventory data. Real-time inventory visibility, powered by an inventory data lake, consolidates vast amounts of transactional and operational data from multiple sources, enabling instant, accurate stock level analysis and demand forecasting.

Connected Warehouse Sensors

Connected warehouse sensors enable real-time inventory visibility by providing continuous data on stock levels, location, and movement, significantly reducing errors and improving accuracy compared to traditional inventory methods that rely on periodic manual counts. This integration enhances supply chain efficiency, accelerates order fulfillment, and minimizes stockouts or overstock scenarios through immediate updates and automated alerts.

Traditional Inventory vs Real-Time Inventory Visibility Infographic

industrydif.com

industrydif.com