Bulk storage maximizes space by storing large quantities of products in open areas, ideal for high-volume, low-variety items. Automated Storage and Retrieval Systems (ASRS) enhance efficiency through precise, computer-controlled handling and retrieval of goods, reducing labor costs and minimizing errors. Choosing between bulk storage and ASRS depends on inventory characteristics, throughput requirements, and warehouse layout optimization.

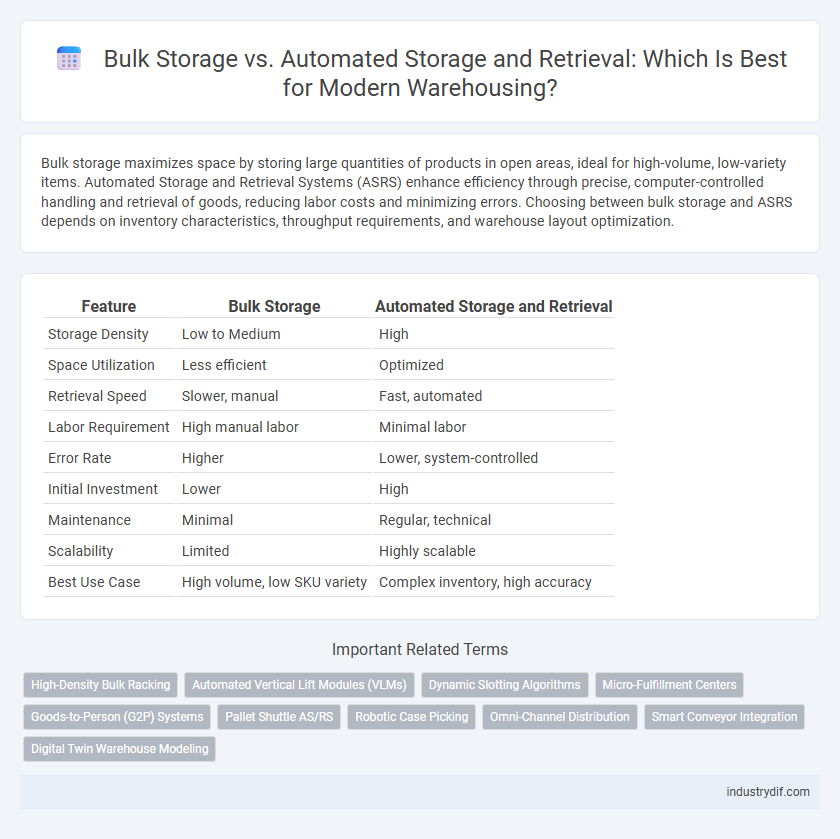

Table of Comparison

| Feature | Bulk Storage | Automated Storage and Retrieval |

|---|---|---|

| Storage Density | Low to Medium | High |

| Space Utilization | Less efficient | Optimized |

| Retrieval Speed | Slower, manual | Fast, automated |

| Labor Requirement | High manual labor | Minimal labor |

| Error Rate | Higher | Lower, system-controlled |

| Initial Investment | Lower | High |

| Maintenance | Minimal | Regular, technical |

| Scalability | Limited | Highly scalable |

| Best Use Case | High volume, low SKU variety | Complex inventory, high accuracy |

Introduction to Bulk Storage and Automated Storage and Retrieval

Bulk storage facilities efficiently store large quantities of homogeneous goods using pallets, bins, or cartons in high-density layouts that maximize space utilization. Automated Storage and Retrieval Systems (AS/RS) employ robotics and computer-controlled technologies to enhance inventory management, enabling rapid, accurate handling and retrieval of individual items or containers. Both methods optimize warehouse operations by balancing storage capacity with throughput requirements, adapting to diverse industry needs from raw materials to finished products.

Defining Bulk Storage: Key Features and Applications

Bulk storage in warehousing involves storing large quantities of goods without individual packaging, ideal for non-perishable and homogeneous products such as raw materials, grains, or construction supplies. Its key features include high-density stacking, minimal handling complexity, and cost-efficiency for slow-moving inventory, often using pallets or bins. Bulk storage is commonly applied in industries like agriculture, mining, and manufacturing where space optimization and ease of access to bulk items are paramount.

What Is Automated Storage and Retrieval? Core Concepts

Automated Storage and Retrieval Systems (AS/RS) utilize computer-controlled systems to automatically place and retrieve loads from defined storage locations, maximizing efficiency and space utilization in warehouses. Core concepts include robotic cranes, conveyors, and shuttle systems integrated with warehouse management software to optimize inventory handling in high-density storage environments. These systems significantly reduce human labor, minimize errors, and increase throughput compared to traditional bulk storage methods.

Space Utilization: Bulk vs Automated Storage

Bulk storage maximizes space by stacking large quantities of homogeneous goods on pallets, often resulting in lower storage density due to wide aisle requirements for forklifts. Automated Storage and Retrieval Systems (AS/RS) enhance space utilization by enabling narrow aisles and high-density vertical storage, significantly increasing pallet positions per square foot. This technology optimizes cubic space use, reduces idle floor space, and supports higher storage capacity in warehouses with limited footprints.

Labor Efficiency and Operational Costs

Bulk storage requires more manual labor for handling and inventory management, increasing labor costs and reducing efficiency in large-scale operations. Automated Storage and Retrieval Systems (AS/RS) significantly reduce labor requirements by utilizing robotics and software to manage storage and retrieval tasks, lowering operational expenses. Implementing AS/RS improves labor efficiency by minimizing human error and accelerating throughput, leading to substantial cost savings in warehousing operations.

Flexibility and Scalability Considerations

Bulk storage offers high flexibility by accommodating diverse product sizes and shapes without extensive equipment changes, making it ideal for warehouses with variable inventory. Automated Storage and Retrieval Systems (AS/RS) provide scalable solutions through modular designs that can expand with increasing throughput demands, enhancing space utilization and operational efficiency. Choosing between bulk storage and AS/RS depends on balancing immediate flexibility needs against long-term scalability and automation goals.

Inventory Accuracy and Management

Bulk storage offers ample space for large quantities of goods but often suffers from lower inventory accuracy due to manual handling and limited visibility. Automated Storage and Retrieval Systems (ASRS) enhance inventory accuracy by using real-time tracking, RFID, and barcode scanning to minimize errors. ASRS also improves inventory management efficiency through faster retrieval times, optimized space utilization, and seamless integration with warehouse management systems (WMS).

Technology Integration and Maintenance

Bulk storage systems primarily rely on manual processes and simple mechanical equipment, leading to lower upfront technology integration but increased long-term labor costs. Automated Storage and Retrieval Systems (AS/RS) integrate advanced robotics, sensors, and warehouse management software, enhancing operational efficiency and inventory accuracy while requiring regular technical maintenance and software updates. The choice between bulk storage and AS/RS hinges on balancing initial technology investment against ongoing maintenance demands and performance benefits.

Typical Industries and Use Cases

Bulk storage is commonly utilized in industries such as agriculture, manufacturing, and construction for handling large quantities of raw materials, bulk goods, and heavy items, offering cost-effective, high-capacity solutions. Automated Storage and Retrieval Systems (AS/RS) find extensive use in e-commerce, pharmaceuticals, and electronics sectors where precision, speed, and inventory accuracy are critical for managing small to medium-sized products. Grocery distribution centers and automotive parts warehouses leverage a hybrid approach, integrating bulk storage for large-volume items with AS/RS for fast-moving, high-value inventory to optimize space and improve operational efficiency.

Choosing Between Bulk Storage and AS/RS: Key Decision Factors

Choosing between bulk storage and Automated Storage and Retrieval Systems (AS/RS) depends on factors like inventory volume, retrieval speed, and space optimization requirements. Bulk storage suits high-volume, low-turnover goods with lower initial investment, while AS/RS offers enhanced accuracy, faster access, and improved labor efficiency for high-turnover inventory. Consideration of warehouse layout, cost constraints, and operational complexity is crucial to determine the best fit for specific warehousing needs.

Related Important Terms

High-Density Bulk Racking

High-density bulk racking maximizes warehouse space by stacking large quantities of palletized goods in compact, accessible rows, enhancing storage efficiency for bulk products. Automated storage and retrieval systems (AS/RS) complement high-density bulk racking by streamlining inventory management and reducing labor costs through precise, automated handling and real-time tracking.

Automated Vertical Lift Modules (VLMs)

Automated Vertical Lift Modules (VLMs) significantly enhance warehouse efficiency by maximizing vertical space and providing rapid, accurate item retrieval compared to traditional bulk storage methods. Integrating VLMs reduces floor footprint while increasing storage density up to 60%, streamlining inventory management through real-time data tracking and minimizing labor costs.

Dynamic Slotting Algorithms

Dynamic slotting algorithms enhance warehouse efficiency by optimizing product placement based on demand patterns, outperforming traditional bulk storage methods that rely on static inventory locations. Automated Storage and Retrieval Systems (AS/RS) leverage these algorithms to minimize travel time and maximize space utilization, driving faster order fulfillment and reduced operational costs.

Micro-Fulfillment Centers

Bulk storage in micro-fulfillment centers maximizes space efficiency by stacking large quantities of homogeneous inventory, while automated storage and retrieval systems (AS/RS) enhance order accuracy and throughput through robotics and real-time inventory management. Integrating AS/RS technology reduces labor costs and increases picking speed, making it ideal for high-demand, small-item consumer goods in urban fulfillment environments.

Goods-to-Person (G2P) Systems

Bulk storage offers high-density solutions for large volumes of homogeneous products, maximizing warehouse space efficiency, while Goods-to-Person (G2P) automated storage and retrieval systems enhance order accuracy and picking speed by bringing items directly to operators. G2P systems reduce labor costs and errors by automating item delivery, making them ideal for handling diverse SKUs and improving overall fulfillment performance.

Pallet Shuttle AS/RS

Bulk storage systems maximize warehouse space by stacking pallets densely on static racks, optimizing for large volumes of similar products with minimal handling complexity. Pallet Shuttle AS/RS enhances storage efficiency through automated shuttles that retrieve pallets within racks, increasing throughput and reducing labor costs while providing dynamic access to individual pallets in high-density storage environments.

Robotic Case Picking

Robotic case picking in automated storage and retrieval systems (AS/RS) enhances accuracy and speed compared to traditional bulk storage by using robots to handle individual cases, reducing human error and increasing throughput. This technology optimizes space utilization and inventory management, enabling warehouses to process high volumes of orders with minimal labor costs and improved operational efficiency.

Omni-Channel Distribution

Bulk storage maximizes space by stacking large quantities of homogeneous products, ideal for high-volume, low-variation inventory in omni-channel distribution. Automated Storage and Retrieval Systems (AS/RS) enhance order accuracy and speed, supporting diverse SKU handling and real-time inventory management critical for meeting omni-channel consumer demands.

Smart Conveyor Integration

Bulk storage maximizes space efficiency by stacking goods in large quantities, while Automated Storage and Retrieval Systems (AS/RS) enhance precision and speed through robotics. Smart conveyor integration streamlines material flow between AS/RS and bulk storage, boosting throughput and reducing manual handling errors.

Digital Twin Warehouse Modeling

Bulk storage relies on high-density stacking for maximizing space efficiency, while automated storage and retrieval systems (AS/RS) enhance operational speed and accuracy through robotics and software integration. Digital twin warehouse modeling enables real-time simulation and optimization of these storage methods by creating a virtual replica, improving inventory management and reducing downtime.

Bulk Storage vs Automated Storage and Retrieval Infographic

industrydif.com

industrydif.com