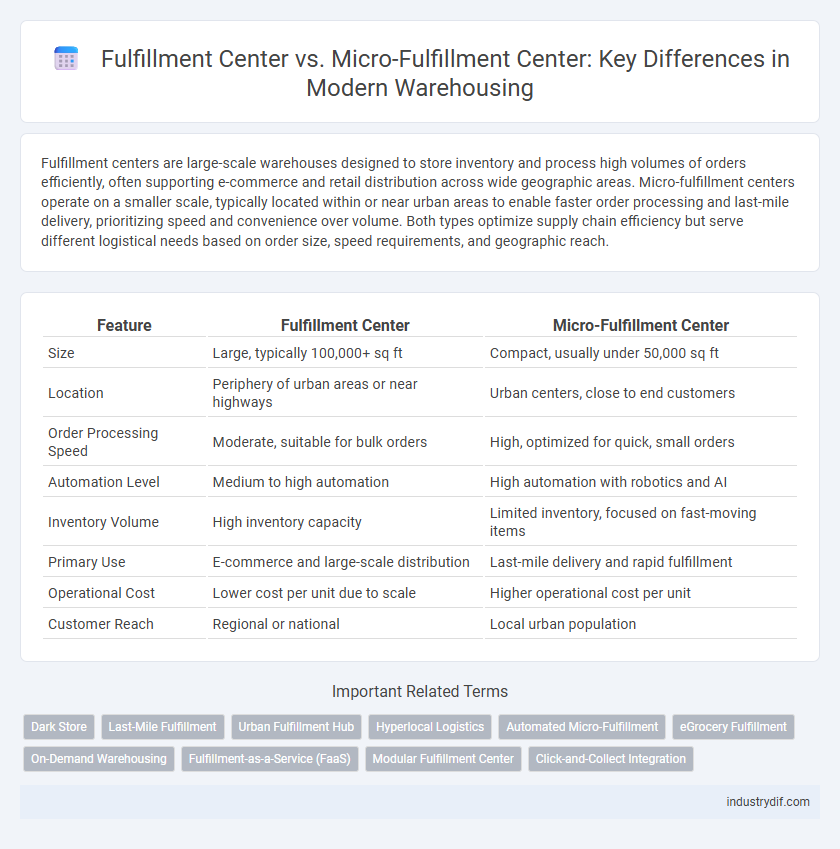

Fulfillment centers are large-scale warehouses designed to store inventory and process high volumes of orders efficiently, often supporting e-commerce and retail distribution across wide geographic areas. Micro-fulfillment centers operate on a smaller scale, typically located within or near urban areas to enable faster order processing and last-mile delivery, prioritizing speed and convenience over volume. Both types optimize supply chain efficiency but serve different logistical needs based on order size, speed requirements, and geographic reach.

Table of Comparison

| Feature | Fulfillment Center | Micro-Fulfillment Center |

|---|---|---|

| Size | Large, typically 100,000+ sq ft | Compact, usually under 50,000 sq ft |

| Location | Periphery of urban areas or near highways | Urban centers, close to end customers |

| Order Processing Speed | Moderate, suitable for bulk orders | High, optimized for quick, small orders |

| Automation Level | Medium to high automation | High automation with robotics and AI |

| Inventory Volume | High inventory capacity | Limited inventory, focused on fast-moving items |

| Primary Use | E-commerce and large-scale distribution | Last-mile delivery and rapid fulfillment |

| Operational Cost | Lower cost per unit due to scale | Higher operational cost per unit |

| Customer Reach | Regional or national | Local urban population |

Definition of Fulfillment Centers

Fulfillment centers are large warehouses designed for storing products, processing orders, and managing inventory for e-commerce and retail businesses, enabling efficient order picking, packing, and shipping at scale. These facilities often integrate advanced automation and warehouse management systems to streamline operations and improve delivery speed. Fulfillment centers differ from micro-fulfillment centers, which are smaller, localized facilities focused on rapid order fulfillment within urban areas.

What Are Micro-Fulfillment Centers?

Micro-fulfillment centers are compact, technology-driven warehousing facilities designed to expedite order processing and delivery within urban areas. These centers utilize automation and robotics to maximize storage efficiency and reduce fulfillment time, enabling faster last-mile delivery for e-commerce retailers. Compared to traditional fulfillment centers, micro-fulfillment centers occupy less space and focus on high-velocity items, supporting same-day or next-day delivery services.

Key Differences Between Fulfillment Centers and Micro-Fulfillment Centers

Fulfillment centers are large-scale warehouses designed to store extensive inventory and process high volumes of orders, typically serving regional or national e-commerce demands. Micro-fulfillment centers prioritize proximity by operating smaller warehouses located near urban areas, enabling faster last-mile delivery and reduced shipping costs. Key differences include order processing speed, space utilization, and integration with automated technology to optimize efficiency in each facility type.

Warehouse Automation in Fulfillment Centers

Fulfillment centers leverage advanced warehouse automation technologies such as robotics, conveyor systems, and automated sorting to efficiently process high volumes of orders. Micro-fulfillment centers prioritize compact, hyper-local automation solutions that integrate AI-driven picking systems and automated storage to accelerate last-mile delivery. Both models optimize inventory management and order accuracy through real-time data analytics, reducing labor costs and boosting throughput in e-commerce supply chains.

Technology Integration in Micro-Fulfillment Centers

Micro-fulfillment centers leverage advanced robotics, AI-driven inventory management, and automated picking systems to optimize space and accelerate order processing compared to traditional fulfillment centers. These technologies enable micro-fulfillment centers to operate efficiently within smaller urban locations, reducing delivery times and enhancing last-mile fulfillment. Integration of real-time data analytics and IoT sensors further refines inventory accuracy and streamlines warehouse operations.

Order Processing Speed: Micro vs. Traditional Fulfillment

Micro-fulfillment centers significantly enhance order processing speed by utilizing automation and proximity to urban areas, enabling same-day or next-hour delivery. Traditional fulfillment centers, typically larger and located in suburban or rural areas, process orders in bulk but often face longer turnaround times due to distance and manual operations. Optimizing order processing speed is critical for e-commerce businesses aiming to meet rising consumer demands for fast and accurate deliveries.

Scalability and Space Requirements

Fulfillment centers typically require large warehouse spaces to handle high volumes of inventory and offer scalable solutions through extensive automation and workforce management. Micro-fulfillment centers leverage compact, urban locations with advanced robotics to optimize space efficiency but may face scalability limitations due to constrained physical footprints. Choosing between the two depends on balancing space availability with the desired capacity for rapid order processing and expansion.

Cost Efficiency and ROI Comparison

Micro-fulfillment centers offer higher cost efficiency by utilizing automated systems and smaller footprints, significantly reducing labor and real estate expenses compared to traditional fulfillment centers. The ROI for micro-fulfillment centers is typically faster due to lower initial capital investment and quicker inventory turnover driven by proximity to end consumers. Traditional fulfillment centers may yield higher absolute volume but face increased operational costs and longer ROI periods.

Ideal Use Cases for Each Model

Fulfillment centers are ideal for high-volume e-commerce businesses requiring large-scale storage and centralized order processing, enabling efficient bulk inventory management and faster shipping for broad geographic regions. Micro-fulfillment centers suit urban areas with dense populations and high demand for rapid delivery, leveraging compact automation to fulfill last-mile orders within hours. Retailers seeking to balance inventory costs with delivery speed often combine both models to optimize warehouse operations and meet customer expectations.

Future Trends in Fulfillment Solutions

Future trends in fulfillment solutions emphasize the growing adoption of micro-fulfillment centers (MFCs) to meet increasing e-commerce demands with faster delivery times and reduced transportation costs. Advanced automation and AI-driven inventory management are transforming traditional fulfillment centers by enhancing accuracy and operational efficiency. Integration of sustainable practices and real-time data analytics further accelerates the evolution of flexible, scalable supply chain networks tailored to dynamic consumer expectations.

Related Important Terms

Dark Store

Fulfillment centers are large-scale warehouses designed to store and process bulk inventory for e-commerce orders, while micro-fulfillment centers are compact facilities located within urban areas to expedite last-mile delivery and improve order accuracy. Dark stores function as retail spaces converted solely into micro-fulfillment centers, optimizing inventory management and enabling faster, more efficient omnichannel fulfillment without serving in-store customers.

Last-Mile Fulfillment

Fulfillment centers are large-scale warehouses designed to store and ship high volumes of inventory across broad regions, optimizing bulk last-mile fulfillment efficiencies, while micro-fulfillment centers operate on a smaller footprint within urban areas to facilitate rapid, localized last-mile delivery, significantly reducing shipping time and costs. Micro-fulfillment centers leverage automation and proximity to customers, enabling faster order processing and enhancing last-mile fulfillment in densely populated markets.

Urban Fulfillment Hub

Urban fulfillment hubs are specialized micro-fulfillment centers strategically located within or near city centers to expedite order processing and reduce last-mile delivery times. These hubs leverage automated systems and compact storage solutions to efficiently handle high-volume e-commerce demand in limited urban spaces.

Hyperlocal Logistics

Fulfillment centers handle large-scale order processing with extensive inventory storage, optimizing supply chain efficiency across wide regions, whereas micro-fulfillment centers specialize in compact, automated operations that enable rapid order fulfillment within urban areas, crucial for hyperlocal logistics. Hyperlocal logistics rely on micro-fulfillment centers to reduce delivery times and costs by placing inventory closer to end customers, enhancing real-time responsiveness and last-mile delivery effectiveness.

Automated Micro-Fulfillment

Automated micro-fulfillment centers leverage advanced robotics and AI-driven systems to maximize storage density and significantly reduce order processing times compared to traditional fulfillment centers. These compact facilities are strategically designed for urban areas to enhance last-mile delivery efficiency while minimizing operational costs and spatial requirements.

eGrocery Fulfillment

Fulfillment centers handle large-scale eGrocery orders with extensive inventory storage and conventional picking processes, optimizing bulk deliveries over wide geographic areas. Micro-fulfillment centers leverage automation and compact layouts near urban areas, enabling rapid order processing and same-day delivery for fresh and perishable grocery items.

On-Demand Warehousing

On-demand warehousing leverages micro-fulfillment centers to enable faster inventory turnover and reduced delivery times by strategically placing smaller facilities closer to urban areas, compared to traditional fulfillment centers that operate larger, centralized spaces. This approach enhances supply chain agility and scalability by optimizing inventory distribution and minimizing last-mile logistics costs.

Fulfillment-as-a-Service (FaaS)

Fulfillment-as-a-Service (FaaS) enhances both Fulfillment Centers and Micro-Fulfillment Centers by streamlining order processing through scalable, cloud-based technologies, enabling faster delivery and improved inventory management. Micro-Fulfillment Centers leverage FaaS to optimize urban logistics with compact, automated solutions, while traditional Fulfillment Centers use FaaS to handle large-scale distribution efficiently across broader geographic areas.

Modular Fulfillment Center

Modular Fulfillment Centers offer scalable, flexible solutions by integrating automated systems within existing warehouse spaces, optimizing order accuracy and processing speed compared to traditional Fulfillment Centers. These centers reduce inventory handling times and improve space utilization, providing a cost-effective alternative to Micro-Fulfillment Centers that focus on ultra-localized inventory for rapid delivery.

Click-and-Collect Integration

Fulfillment centers typically handle large-scale order processing with extensive inventory storage, while micro-fulfillment centers optimize rapid, localized inventory management to enhance click-and-collect integration by reducing last-mile delivery times. Micro-fulfillment centers leverage automated systems within urban areas, facilitating faster order pick-up and improving customer convenience in omnichannel retail strategies.

Fulfillment Center vs Micro-Fulfillment Center Infographic

industrydif.com

industrydif.com