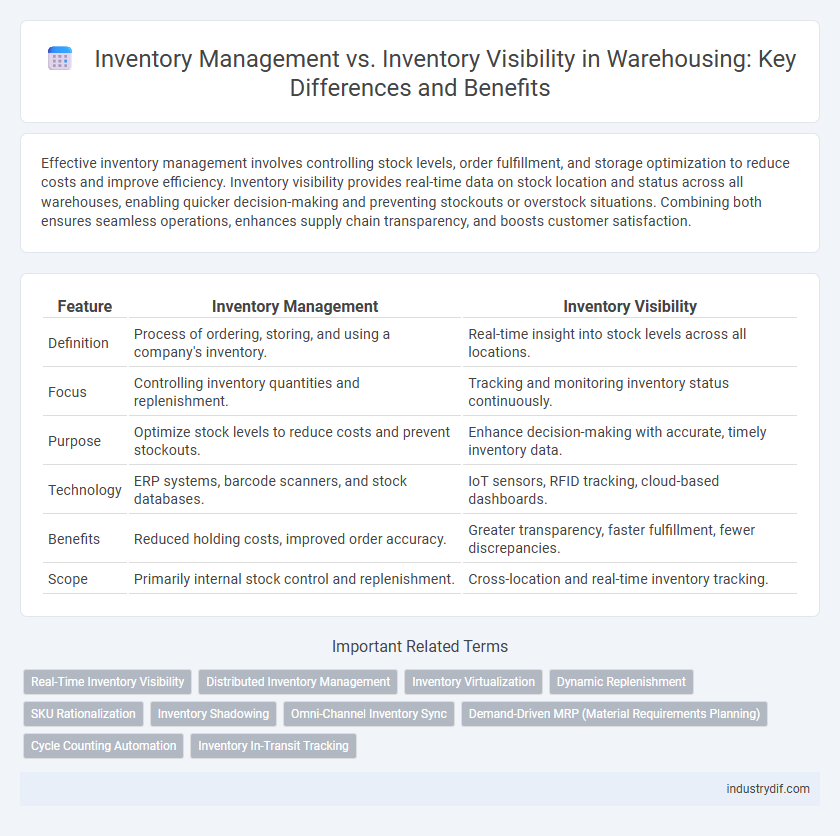

Effective inventory management involves controlling stock levels, order fulfillment, and storage optimization to reduce costs and improve efficiency. Inventory visibility provides real-time data on stock location and status across all warehouses, enabling quicker decision-making and preventing stockouts or overstock situations. Combining both ensures seamless operations, enhances supply chain transparency, and boosts customer satisfaction.

Table of Comparison

| Feature | Inventory Management | Inventory Visibility |

|---|---|---|

| Definition | Process of ordering, storing, and using a company's inventory. | Real-time insight into stock levels across all locations. |

| Focus | Controlling inventory quantities and replenishment. | Tracking and monitoring inventory status continuously. |

| Purpose | Optimize stock levels to reduce costs and prevent stockouts. | Enhance decision-making with accurate, timely inventory data. |

| Technology | ERP systems, barcode scanners, and stock databases. | IoT sensors, RFID tracking, cloud-based dashboards. |

| Benefits | Reduced holding costs, improved order accuracy. | Greater transparency, faster fulfillment, fewer discrepancies. |

| Scope | Primarily internal stock control and replenishment. | Cross-location and real-time inventory tracking. |

Introduction to Inventory Management and Inventory Visibility

Inventory management involves the systematic approach to sourcing, storing, and controlling inventory levels to meet customer demand efficiently. Inventory visibility refers to real-time access to inventory data across multiple locations, enabling accurate tracking and timely decision-making. Combining effective inventory management with enhanced inventory visibility reduces stockouts, minimizes excess inventory, and improves overall supply chain performance.

Defining Inventory Management

Inventory management involves the systematic tracking, ordering, and storage of goods to ensure optimal stock levels and reduce carrying costs. It utilizes tools like barcode scanning and automated reorder points to maintain accuracy and efficiency. Effective inventory management directly impacts supply chain performance by minimizing stockouts and overstock situations.

Understanding Inventory Visibility

Inventory visibility provides real-time insights into stock levels, locations, and movement across the entire supply chain, enabling more accurate demand forecasting and reducing stockouts. Unlike inventory management, which focuses on controlling and optimizing stock, inventory visibility emphasizes transparency and accessibility of data through technologies such as RFID, barcode scanning, and inventory tracking software. Enhanced inventory visibility drives operational efficiency by allowing swift decision-making and improving coordination between warehouses, suppliers, and distribution centers.

Key Differences Between Inventory Management and Inventory Visibility

Inventory management focuses on tracking and controlling stock levels, ensuring optimal reorder points, and minimizing carrying costs through efficient demand forecasting and stock replenishment processes. Inventory visibility provides real-time access to inventory data across all locations, enabling companies to monitor stock status, detect discrepancies, and make informed decisions instantly. The key difference lies in inventory management's operational control versus inventory visibility's emphasis on transparency and accessibility of inventory information throughout the supply chain.

Importance of Inventory Accuracy in Warehousing

Inventory accuracy in warehousing is crucial for effective inventory management and enhanced inventory visibility, directly impacting order fulfillment and reducing stock discrepancies. Accurate inventory data ensures real-time tracking, efficient replenishment, and minimizes costly errors such as stockouts or overstocking. Maintaining precise inventory records supports seamless supply chain operations and drives operational efficiency in warehouse management systems.

Technology’s Role in Enhancing Inventory Visibility

Advanced technologies such as RFID, IoT sensors, and cloud-based platforms significantly enhance inventory visibility by providing real-time tracking and accurate stock data across multiple locations. These innovations enable warehouses to reduce errors, optimize stock levels, and improve order fulfillment speed. Integrating AI-driven analytics further empowers supply chain managers to anticipate demand fluctuations and streamline inventory replenishment processes.

Benefits of Effective Inventory Management

Effective inventory management minimizes stockouts and overstock situations by maintaining optimal stock levels, thereby reducing carrying costs and improving cash flow. Enhanced inventory accuracy streamlines order fulfillment, boosting customer satisfaction through timely delivery and fewer errors. Real-time data integration supports informed decision-making and demand forecasting, driving operational efficiency and minimizing waste.

Challenges in Achieving Inventory Visibility

Challenges in achieving inventory visibility stem from disparate data sources and real-time tracking limitations, which complicate accurate stock level assessment across multiple warehouses. Legacy inventory management systems often lack integration capabilities, leading to data silos and delayed information flows. Furthermore, inconsistencies in SKU identification and variable data quality hinder synchronized inventory updates, reducing overall supply chain responsiveness.

Impact of Inventory Management vs Inventory Visibility on Supply Chain Efficiency

Effective inventory management controls stock levels and order processes to minimize costs and prevent overstock or stockouts, directly enhancing supply chain efficiency. Inventory visibility provides real-time data access across the supply chain, enabling accurate demand forecasting and rapid response to disruptions. Combining robust inventory management with high inventory visibility optimizes resource allocation, reduces lead times, and improves overall supply chain performance.

Future Trends in Inventory Management and Inventory Visibility

Enhanced inventory management leverages AI-driven analytics and IoT sensors to predict demand patterns and automate stock replenishment, while inventory visibility increasingly integrates blockchain for real-time, immutable tracking across the supply chain. Future trends highlight the convergence of advanced data platforms and cloud-based solutions, enabling seamless synchronization between warehouse operations and external logistics partners. Robotics and augmented reality are also set to redefine inventory audits and accuracy, fostering smarter, more resilient warehousing ecosystems.

Related Important Terms

Real-Time Inventory Visibility

Real-time inventory visibility enhances inventory management by providing accurate, up-to-the-minute data on stock levels, locations, and movement within the warehouse. This immediate insight reduces stock discrepancies, optimizes replenishment cycles, and improves order fulfillment accuracy, driving operational efficiency and customer satisfaction.

Distributed Inventory Management

Distributed inventory management optimizes stock allocation across multiple warehouses, enhancing order fulfillment speed and reducing carrying costs. Inventory visibility provides real-time insights into stock levels and locations, enabling businesses to make data-driven decisions and respond swiftly to demand fluctuations.

Inventory Virtualization

Inventory virtualization enhances inventory management by providing real-time, centralized visibility across multiple warehouse locations, enabling precise tracking and forecasting of stock levels. This digital representation of physical inventory streamlines decision-making, reduces stockouts, and improves overall warehouse efficiency.

Dynamic Replenishment

Dynamic replenishment in inventory management enables real-time stock adjustments based on demand fluctuations, reducing stockouts and overstock scenarios. Enhanced inventory visibility provides accurate, up-to-the-minute data that drives automated replenishment decisions, optimizing warehouse efficiency and customer satisfaction.

SKU Rationalization

SKU rationalization enhances inventory management by identifying and eliminating underperforming stock-keeping units, reducing carrying costs and optimizing warehouse space. Improved inventory visibility provides real-time data on SKUs, enabling precise demand forecasting and efficient replenishment strategies.

Inventory Shadowing

Inventory shadowing occurs when discrepancies between recorded inventory levels and actual stock create hidden stock imbalances, undermining effective inventory management. Enhancing inventory visibility through real-time tracking systems and automated data capture minimizes shadow inventory, improving accuracy and operational efficiency in warehousing.

Omni-Channel Inventory Sync

Inventory management optimizes stock levels and replenishment processes, while inventory visibility provides real-time data across multiple sales channels. Omni-channel inventory sync integrates these functions, ensuring accurate stock information is consistently updated to meet customer demand and reduce fulfillment errors.

Demand-Driven MRP (Material Requirements Planning)

Demand-Driven MRP integrates real-time inventory visibility with advanced inventory management to optimize stock levels based on actual demand signals, reducing excess inventory and minimizing stockouts. This approach leverages precise data from warehouse operations to enhance production scheduling and supply chain responsiveness, ensuring materials are available exactly when needed.

Cycle Counting Automation

Cycle counting automation enhances inventory management by providing real-time data accuracy and reducing human error in stock reconciliation. Improved inventory visibility through automated cycle counts enables efficient decision-making and optimizes warehouse operations by minimizing stock discrepancies.

Inventory In-Transit Tracking

Inventory management optimizes stock control through systematic tracking and replenishment, while inventory visibility enhances real-time monitoring of inventory locations across the supply chain. Inventory in-transit tracking specifically enables precise tracking of goods between warehouses and distribution centers, reducing delays and improving order accuracy.

Inventory Management vs Inventory Visibility Infographic

industrydif.com

industrydif.com