Pallet racking is a versatile and cost-effective storage solution ideal for high-density, slow-moving inventory with easy accessibility. Shuttle racking enhances efficiency by utilizing automated shuttles to move pallets within the rack, reducing labor costs and maximizing space utilization for high-throughput operations. Choosing between pallet racking and shuttle racking depends on inventory turnover rates, budget constraints, and warehouse automation goals.

Table of Comparison

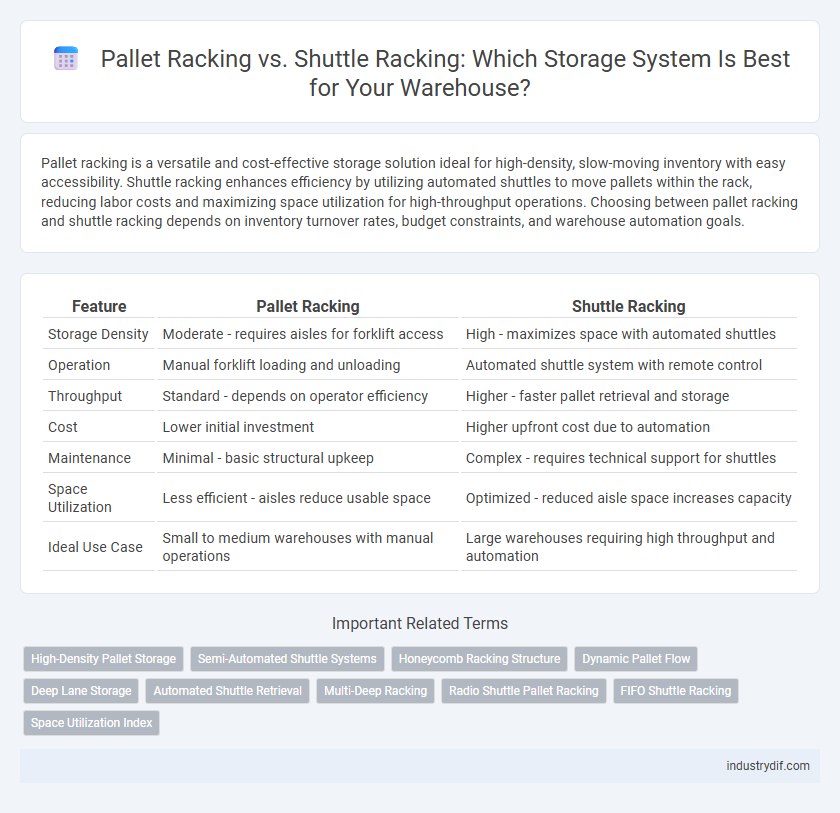

| Feature | Pallet Racking | Shuttle Racking |

|---|---|---|

| Storage Density | Moderate - requires aisles for forklift access | High - maximizes space with automated shuttles |

| Operation | Manual forklift loading and unloading | Automated shuttle system with remote control |

| Throughput | Standard - depends on operator efficiency | Higher - faster pallet retrieval and storage |

| Cost | Lower initial investment | Higher upfront cost due to automation |

| Maintenance | Minimal - basic structural upkeep | Complex - requires technical support for shuttles |

| Space Utilization | Less efficient - aisles reduce usable space | Optimized - reduced aisle space increases capacity |

| Ideal Use Case | Small to medium warehouses with manual operations | Large warehouses requiring high throughput and automation |

Understanding Pallet Racking Systems

Pallet racking systems provide organized storage solutions that maximize warehouse space by stacking pallets vertically, benefiting operations that require easy access and inventory visibility. Shuttle racking, a subset of pallet racking, uses automated shuttles to transport pallets within deep lane storage, enhancing efficiency in high-density warehouses. Understanding the differences helps businesses select the best system based on factors like inventory turnover, space utilization, and picking frequency.

What is Shuttle Racking?

Shuttle racking is an advanced warehouse storage system that uses a motorized shuttle to transport pallets within racking lanes, significantly increasing storage density and retrieval speed. Unlike traditional pallet racking, shuttle racking eliminates the need for forklifts to enter aisles, reducing labor costs and minimizing product damage. This system is ideal for high-volume operations with homogeneous products, optimizing space utilization and improving warehouse efficiency.

Key Differences Between Pallet and Shuttle Racking

Pallet racking systems rely on forklift access for loading and unloading individual pallets, making them ideal for diverse inventory with frequent SKU variations. Shuttle racking employs automated shuttles to transport pallets within deep rack lanes, enhancing storage density and reducing labor costs in high-volume, repetitive picking environments. Key differences include automation level, space utilization, and operational efficiency, where shuttle racking outperforms in compactness and speed, while pallet racking offers greater flexibility for mixed loads.

Storage Density Comparison

Pallet racking systems typically offer moderate storage density by allowing easy access to individual pallets with standard aisle widths, optimizing space for various inventory types. Shuttle racking significantly increases storage density by using automated shuttles to transport pallets within narrower aisles, maximizing vertical and horizontal space utilization. The choice between pallet racking and shuttle racking depends on balancing storage density needs with retrieval speed and operational complexity.

Accessibility and Picking Efficiency

Pallet racking offers high accessibility with direct aisle access to each pallet, enabling straightforward picking and inventory management. Shuttle racking enhances picking efficiency by using automated shuttles to transport pallets within deep lanes, reducing travel time and increasing storage density. The choice between the two depends on balancing throughput requirements with space optimization goals in warehouse operations.

Cost Analysis: Pallet vs Shuttle Racking

Pallet racking systems typically involve lower initial investment costs due to simpler installation and standardized components, making them ideal for warehouses with moderate inventory turnover and fewer SKUs. Shuttle racking, while requiring higher upfront expenses for automated shuttles and specialized infrastructure, significantly reduces labor costs and improves storage density, enhancing long-term operational savings in high-volume, fast-moving environments. Evaluating total cost of ownership involves considering factors such as space utilization, labor efficiency, equipment depreciation, and maintenance expenses for both pallet and shuttle racking solutions.

Suitable Applications for Each Racking System

Pallet racking systems are ideal for warehouses with diverse inventory types and moderate turnover, offering flexibility in storing various pallet sizes and easy access for forklift operations. Shuttle racking excels in high-density storage environments with uniform products, optimizing space by using automated shuttles to transport pallets within deep lanes, thereby increasing storage capacity and efficiency. Choosing between these systems depends on inventory turnover rates, product uniformity, and warehouse layout, with pallet racking suited for dynamic picking needs and shuttle racking best for bulk storage.

Installation and Maintenance Needs

Pallet racking systems require straightforward installation with standard anchoring and bolting processes, making maintenance primarily focused on periodic inspections and repairs of structural components. Shuttle racking systems involve more complex installation due to the integration of automated shuttles and electronic controls, necessitating specialized setup and ongoing technical maintenance to ensure the motorized shuttles operate smoothly. Regular software updates and mechanical servicing are critical for shuttle racking to optimize performance and minimize downtime compared to the simpler upkeep of conventional pallet racking.

Space Optimization and Warehouse Layout

Pallet Racking systems maximize vertical storage space by utilizing multiple levels of pallets, ideal for warehouses with standard forklift operations and a variety of SKU sizes. Shuttle Racking enhances space optimization by reducing aisle widths through automated shuttles that retrieve pallets, significantly increasing storage density and enabling a more compact warehouse layout. Choosing Shuttle Racking improves operational flow and storage capacity in high-throughput environments, while Pallet Racking offers flexibility for mixed pallet sizes and manual handling.

Choosing the Right Racking Solution

Selecting the appropriate racking solution depends on warehouse size, inventory turnover, and storage density requirements. Pallet racking offers flexibility and easy access for diverse pallet loads, making it ideal for warehouses with varied SKUs and moderate throughput. Shuttle racking maximizes space utilization and increases picking speed by using automated shuttles, suitable for high-density storage and high-volume operations with uniform products.

Related Important Terms

High-Density Pallet Storage

Shuttle racking maximizes high-density pallet storage by utilizing automated shuttles to transport pallets within compact aisles, significantly increasing storage capacity compared to traditional pallet racking. Pallet racking offers greater accessibility and flexibility for inventory management but requires wider aisles, reducing overall storage density.

Semi-Automated Shuttle Systems

Semi-automated shuttle racking systems maximize warehouse space by utilizing motorized shuttles to efficiently store and retrieve pallets within deep lanes, reducing forklift travel time compared to traditional pallet racking. This technology enhances throughput and inventory density by automating the transport of pallets on multiple levels, streamlining order fulfillment while requiring less labor and minimizing human error.

Honeycomb Racking Structure

Honeycomb racking structures enhance pallet racking systems by providing optimal load distribution and stability through a grid-like framework that maximizes vertical and horizontal storage space. Compared to shuttle racking, honeycomb designs offer superior modularity and easier access, improving picking efficiency in high-density warehousing environments.

Dynamic Pallet Flow

Dynamic pallet flow systems in shuttle racking optimize space utilization by using gravity rollers to move pallets automatically, enhancing inventory rotation and reducing labor costs compared to traditional pallet racking. This efficient flow-through design supports high-density storage and faster retrieval times, making it ideal for warehouses with high SKU variability and strict FIFO requirements.

Deep Lane Storage

Deep lane storage optimizes warehouse space by utilizing pallet racking and shuttle racking systems designed for high-density storage of similar SKUs. Shuttle racking enhances retrieval speed and reduces labor costs by employing automated shuttle vehicles that navigate deep lanes, whereas pallet racking relies on forklifts for access, making shuttle systems more efficient for deep lane applications.

Automated Shuttle Retrieval

Automated Shuttle Retrieval systems in shuttle racking significantly enhance warehouse efficiency by enabling high-density storage and faster access to pallets compared to traditional pallet racking. These systems utilize remote-controlled shuttles to transport goods within storage lanes, reducing labor costs and improving order picking speed in automated warehouses.

Multi-Deep Racking

Multi-deep racking systems like pallet racking and shuttle racking significantly increase warehouse storage density but differ in accessibility and automation; pallet racking offers straightforward access to each pallet ideal for mixed SKU storage, while shuttle racking utilizes automated shuttles to move pallets deep into storage lanes, optimizing space for high-volume, homogeneous goods. Choosing between these systems depends on warehouse throughput, SKU variety, and desired labor reduction, with shuttle racking excelling in minimizing aisle space and manual handling for bulk inventory.

Radio Shuttle Pallet Racking

Radio Shuttle Pallet Racking enhances storage density and operational efficiency by using a remote-controlled shuttle to move pallets within deep rack lanes, reducing forklift travel and accelerating pallet handling compared to traditional Pallet Racking. This technology optimizes space utilization in high-volume warehouses, supports heavy loads up to several tons per shuttle, and significantly improves throughput in last-in, first-out (LIFO) inventory systems.

FIFO Shuttle Racking

FIFO Shuttle Racking enhances warehouse efficiency by combining the high-density storage capabilities of shuttle racking with first-in, first-out inventory management, ensuring product rotation and minimizing stock obsolescence. Unlike traditional pallet racking, FIFO shuttle systems use automated shuttles to retrieve pallets in sequential order, optimizing space utilization and reducing labor costs in fast-moving warehouse environments.

Space Utilization Index

Pallet racking systems typically offer a space utilization index of around 60-70%, providing straightforward access to individual pallets but requiring wider aisles. Shuttle racking enhances space utilization to over 80% by minimizing aisle width and maximizing storage density through automated shuttles that transport pallets within deep lanes.

Pallet Racking vs Shuttle Racking Infographic

industrydif.com

industrydif.com