Manual picking in warehousing relies on workers physically moving through aisles to locate and retrieve items, which can lead to increased labor costs and longer order fulfillment times. The goods-to-person system automates item retrieval by bringing products directly to workers, significantly enhancing accuracy and efficiency in inventory handling. Implementing goods-to-person technology reduces travel time and errors, driving higher productivity and faster turnaround times in warehouse operations.

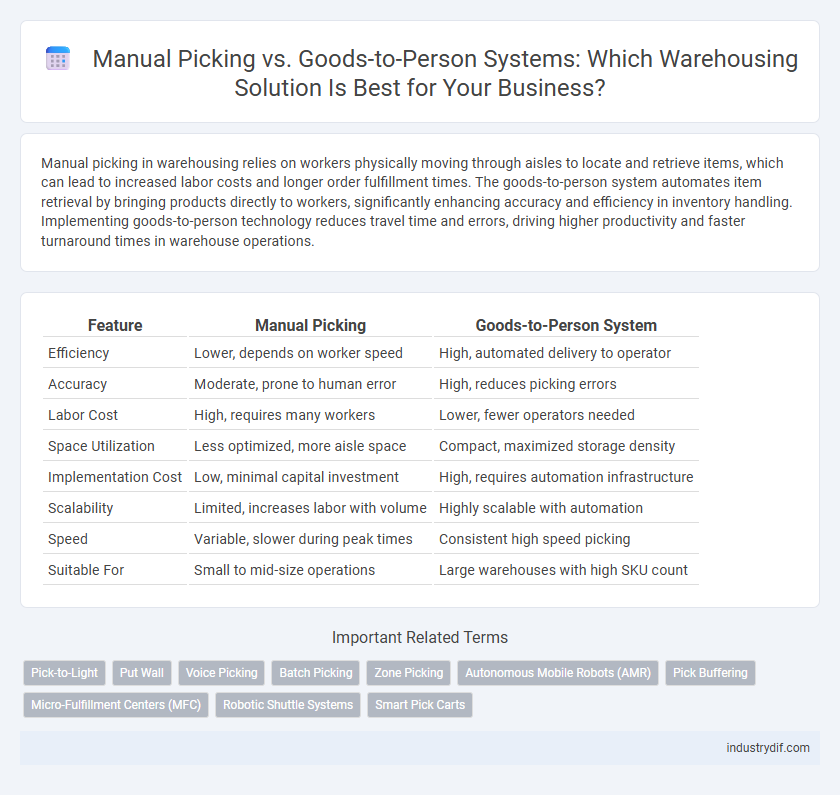

Table of Comparison

| Feature | Manual Picking | Goods-to-Person System |

|---|---|---|

| Efficiency | Lower, depends on worker speed | High, automated delivery to operator |

| Accuracy | Moderate, prone to human error | High, reduces picking errors |

| Labor Cost | High, requires many workers | Lower, fewer operators needed |

| Space Utilization | Less optimized, more aisle space | Compact, maximized storage density |

| Implementation Cost | Low, minimal capital investment | High, requires automation infrastructure |

| Scalability | Limited, increases labor with volume | Highly scalable with automation |

| Speed | Variable, slower during peak times | Consistent high speed picking |

| Suitable For | Small to mid-size operations | Large warehouses with high SKU count |

Introduction to Manual Picking and Goods-to-Person Systems

Manual picking involves warehouse workers physically retrieving items from storage locations, which can lead to increased labor costs and slower order fulfillment. Goods-to-Person (GTP) systems automate this process by using robotics and automated conveyors to bring items directly to the worker, significantly improving efficiency and accuracy. Implementing GTP systems reduces picking errors and enhances productivity in high-volume warehousing environments.

Key Differences Between Manual and Automated Picking

Manual picking relies on workers navigating warehouse aisles to locate and retrieve items, often leading to longer picking times and higher labor costs. Goods-to-person systems use automated conveyors and robots to transport items directly to the picker, significantly increasing efficiency and accuracy. Inventory accuracy, picking speed, and scalability are the primary factors differentiating manual picking from automated goods-to-person technology.

Workflow Overview: Manual vs Goods-to-Person

Manual picking involves workers physically navigating warehouse aisles to locate and retrieve items, which can increase pick times and human error. Goods-to-Person systems automate item presentation by bringing products directly to workers via robotics, significantly improving efficiency and accuracy. This shift in workflow minimizes travel time, reduces fatigue, and optimizes order fulfillment speed.

Labor Requirements and Efficiency

Manual picking in warehousing demands higher labor requirements, as workers must travel between storage locations, increasing physical effort and time per order. Goods-to-Person (GTP) systems optimize efficiency by automating item retrieval, significantly reducing walking time and labor costs while boosting order accuracy and throughput. Implementing GTP technology minimizes workforce dependency and enhances productivity metrics in high-volume distribution centers.

Accuracy and Error Reduction in Order Picking

Manual picking often leads to higher error rates due to human fatigue and miscommunication, with accuracy typically ranging between 85% to 95%. Goods-to-Person (GTP) systems significantly improve order picking accuracy, achieving rates above 99% by automating item delivery directly to the operator and minimizing manual handling. Implementing GTP technology reduces picking errors and enhances inventory accuracy, resulting in improved customer satisfaction and lower operational costs.

Scalability and Flexibility Considerations

Manual picking offers high flexibility for diverse product ranges and fluctuating order volumes but faces scalability limitations due to labor intensity and increased error rates as volume grows. Goods-to-person systems enhance scalability by automating item retrieval, reducing pick times, and maintaining accuracy, yet they require substantial upfront investment and can be less adaptable to sudden changes in product variety. Warehouses must assess order complexity, volume growth projections, and capital availability to choose between these picking methods for optimized operational efficiency.

Cost Implications: Initial Investment and ROI

Manual picking involves lower initial investment costs as it primarily requires shelving, labor, and basic equipment but often leads to higher ongoing labor expenses and slower order fulfillment. Goods-to-Person (G2P) systems demand significant upfront capital for automation technology, robotics, and integrated software but can drastically reduce labor costs, improve accuracy, and accelerate throughput, resulting in a faster return on investment (ROI). Evaluating total cost of ownership and ROI timelines is critical for businesses aiming to optimize warehouse efficiency and scalability.

Safety and Ergonomics in Warehouse Operations

Manual picking exposes workers to repetitive motions and heavy lifting, increasing the risk of musculoskeletal injuries and workplace accidents. Goods-to-Person systems enhance safety by automating item retrieval, reducing physical strain and minimizing human error. Ergonomic improvements in Goods-to-Person setups lead to better posture and decreased fatigue, promoting overall worker well-being in warehouse operations.

Integration with Warehouse Management Systems

Manual picking relies heavily on human operators interacting directly with inventory, which can lead to slower data capture and increased errors in Warehouse Management Systems (WMS) integration. Goods-to-Person (G2P) systems offer seamless integration with advanced WMS software, enabling real-time inventory updates, optimized picking routes, and enhanced accuracy through automation and robotics. The direct communication between G2P systems and WMS improves efficiency and scalability in warehouse operations, reducing labor costs and boosting throughput.

Future Trends in Warehouse Picking Technologies

Future trends in warehouse picking technologies increasingly favor Goods-to-Person (G2P) systems due to their ability to enhance picking accuracy and reduce labor costs. Automation advancements and integration with AI-driven inventory management enable faster order fulfillment and scalability in complex supply chains. Manual picking methods may persist in niche applications but are expected to decline as warehouses adopt smart, robotic-assisted solutions for greater efficiency.

Related Important Terms

Pick-to-Light

Pick-to-Light technology enhances manual picking by reducing errors and increasing order accuracy through visual indicators guiding workers to specific items, significantly improving efficiency compared to traditional methods. Warehouses implementing Pick-to-Light systems report faster pick times and reduced training requirements, streamlining operations in high-volume order fulfillment environments.

Put Wall

Put wall systems in warehousing enhance manual picking efficiency by organizing items into designated compartments, reducing travel time and errors compared to traditional open-floor picking. Integrating put walls with goods-to-person technology optimizes order fulfillment speed and accuracy by combining automated item delivery with precise manual sorting.

Voice Picking

Voice picking enhances manual picking efficiency by enabling hands-free, eyes-free order selection, reducing errors and speeding up the process compared to traditional methods. Integrating voice-directed technology within Goods-to-Person systems further streamlines pick accuracy and worker productivity in warehouse operations.

Batch Picking

Batch picking increases efficiency in manual picking by consolidating multiple orders, reducing travel time and improving throughput; however, goods-to-person systems automate batch picking, enhancing accuracy and speed by delivering items directly to the operator. Implementing goods-to-person solutions can significantly reduce labor costs and error rates compared to traditional manual batch picking processes.

Zone Picking

Zone picking in warehousing divides the picking area into distinct zones where workers manually pick items assigned to their specific zone, increasing efficiency by reducing travel time and minimizing errors. The Goods-to-Person (GTP) system automates this process by delivering items directly to the worker's station, which significantly enhances speed and accuracy but requires higher initial investment and infrastructure.

Autonomous Mobile Robots (AMR)

Autonomous Mobile Robots (AMR) in goods-to-person systems enhance warehouse efficiency by reducing manual picking errors and increasing order fulfillment speed through automated item retrieval and delivery. AMRs optimize space utilization and labor costs while providing scalable solutions adaptable to varying inventory volumes and picking complexities.

Pick Buffering

Manual picking relies on workers physically navigating aisles to collect items, which can cause bottlenecks and slow down order fulfillment due to limited pick buffering capacity. Goods-to-Person systems enhance pick buffering by delivering items directly to the picker, increasing throughput, reducing travel time, and improving overall operational efficiency in warehousing.

Micro-Fulfillment Centers (MFC)

Manual picking in Micro-Fulfillment Centers (MFCs) often results in slower order processing times and higher error rates compared to Goods-to-Person (G2P) systems, which utilize automation to deliver items directly to workers, increasing efficiency and accuracy. G2P systems in MFCs optimize space utilization and reduce labor costs, enabling faster fulfillment of high-volume, small-batch orders common in urban retail environments.

Robotic Shuttle Systems

Robotic shuttle systems in warehousing offer significant efficiency improvements over manual picking by automating the retrieval and transportation of goods, reducing labor costs and picking errors. These systems integrate seamlessly with goods-to-person technology, enhancing throughput rates and optimizing space utilization compared to traditional manual methods.

Smart Pick Carts

Smart pick carts enhance manual picking by integrating automation and real-time data, significantly increasing accuracy and productivity in warehousing operations. These carts optimize workflow by guiding operators through orders with intelligent routing and inventory management, reducing picking errors and minimizing travel time compared to traditional manual systems.

Manual Picking vs Goods-to-Person System Infographic

industrydif.com

industrydif.com