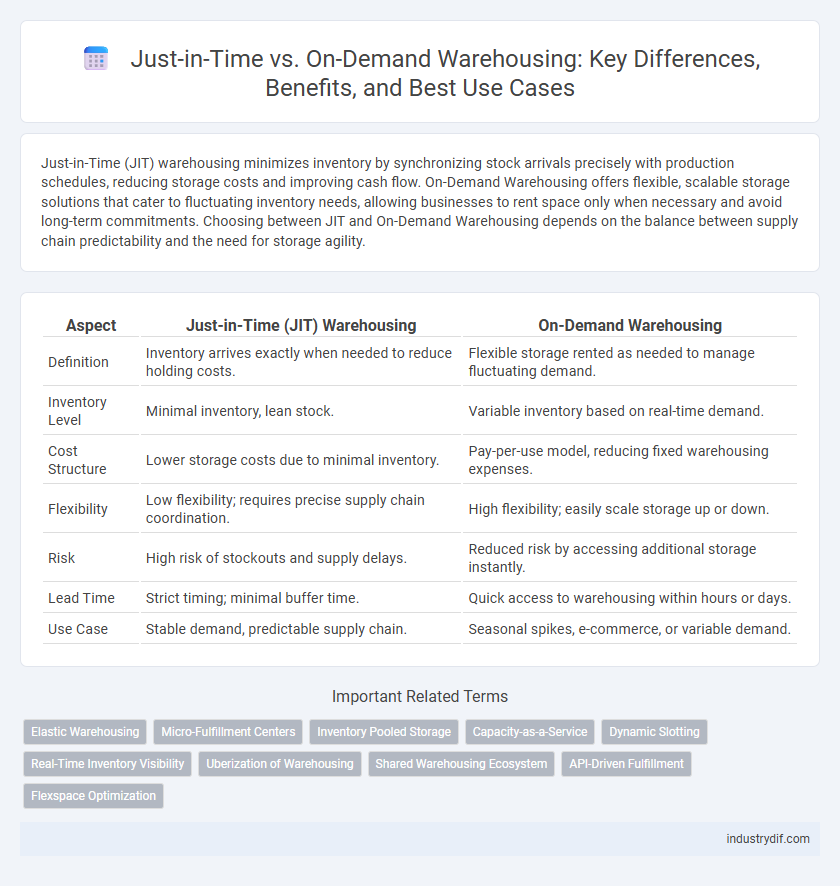

Just-in-Time (JIT) warehousing minimizes inventory by synchronizing stock arrivals precisely with production schedules, reducing storage costs and improving cash flow. On-Demand Warehousing offers flexible, scalable storage solutions that cater to fluctuating inventory needs, allowing businesses to rent space only when necessary and avoid long-term commitments. Choosing between JIT and On-Demand Warehousing depends on the balance between supply chain predictability and the need for storage agility.

Table of Comparison

| Aspect | Just-in-Time (JIT) Warehousing | On-Demand Warehousing |

|---|---|---|

| Definition | Inventory arrives exactly when needed to reduce holding costs. | Flexible storage rented as needed to manage fluctuating demand. |

| Inventory Level | Minimal inventory, lean stock. | Variable inventory based on real-time demand. |

| Cost Structure | Lower storage costs due to minimal inventory. | Pay-per-use model, reducing fixed warehousing expenses. |

| Flexibility | Low flexibility; requires precise supply chain coordination. | High flexibility; easily scale storage up or down. |

| Risk | High risk of stockouts and supply delays. | Reduced risk by accessing additional storage instantly. |

| Lead Time | Strict timing; minimal buffer time. | Quick access to warehousing within hours or days. |

| Use Case | Stable demand, predictable supply chain. | Seasonal spikes, e-commerce, or variable demand. |

Introduction to Just-in-Time and On-Demand Warehousing

Just-in-Time (JIT) warehousing focuses on minimizing inventory levels by receiving goods only as they are needed in the production process, reducing storage costs and waste. On-Demand Warehousing offers flexible, scalable storage solutions by allowing businesses to rent warehouse space dynamically based on current needs, optimizing capacity and cash flow. Both models enhance supply chain efficiency but cater to different operational strategies and demand patterns.

Key Differences Between Just-in-Time and On-Demand Warehousing

Just-in-Time (JIT) warehousing emphasizes minimizing inventory by receiving goods only as needed for production, reducing storage costs but requiring precise demand forecasting and supplier reliability. On-Demand warehousing offers flexible, scalable storage solutions activated as business needs fluctuate, enabling companies to avoid long-term leases and adjust capacity dynamically. The key difference lies in JIT's focus on inventory timing and efficiency, contrasted with On-Demand's prioritization of warehousing flexibility and capacity scalability.

Core Principles of Just-in-Time Warehousing

Just-in-Time warehousing centers on minimizing inventory levels by synchronizing supply with production schedules to reduce storage costs and increase efficiency. It relies on precise demand forecasting, timely deliveries, and strong supplier relationships to ensure materials arrive exactly when needed. This approach enhances cash flow and lowers waste by avoiding excess stock and reducing warehouse space requirements.

Benefits of Just-in-Time Warehousing

Just-in-Time warehousing minimizes inventory holding costs by synchronizing stock arrivals precisely with production schedules, reducing the need for excess storage space. This approach enhances cash flow and operational efficiency by lowering waste and avoiding overproduction. Companies benefit from increased responsiveness to market demands while maintaining lean supply chain management.

Core Principles of On-Demand Warehousing

On-demand warehousing operates on the principle of flexible, short-term storage solutions tailored to fluctuating inventory needs, enabling businesses to scale warehousing capacity without long-term commitments. It leverages real-time data and digital platforms to connect warehouse providers with shippers instantly, optimizing space utilization and reducing overhead costs. This model emphasizes agility, cost efficiency, and responsiveness to variable supply chain demands, contrasting with traditional fixed-space, long-term warehousing approaches.

Advantages of On-Demand Warehousing

On-Demand Warehousing offers significant flexibility by allowing businesses to temporarily scale storage space based on fluctuating inventory needs, reducing long-term fixed costs. It enhances supply chain efficiency through faster response times and localized storage options, minimizing transportation expenses and delivery delays. This model supports dynamic market demands by providing access to a broad network of warehouse locations without the overhead of owning or leasing dedicated facilities.

Operational Challenges and Limitations

Just-in-Time warehousing faces operational challenges such as strict timing requirements that can lead to stockouts or delays if supply chain disruptions occur, demanding highly coordinated logistics and real-time inventory management systems. On-Demand warehousing, while offering flexibility and scalability, can suffer from inconsistent space availability and limited control over inventory handling standards, which complicates synchronization with core supply chain operations. Both models require advanced forecasting and technology integration to address limitations in responsiveness and reliability in fast-paced distribution environments.

Technology's Role in Both Warehousing Models

Technology drives efficiency in Just-in-Time warehousing by enabling real-time inventory tracking, automated demand forecasting, and seamless supplier integration to minimize stock levels and reduce holding costs. In On-Demand warehousing, advanced cloud platforms and IoT sensors facilitate flexible space utilization, dynamic capacity scaling, and rapid order fulfillment to meet fluctuating customer demands. Both models rely heavily on data analytics and AI-powered systems to optimize inventory turnover and streamline supply chain operations.

Industry Suitability: Just-in-Time vs On-Demand

Just-in-Time warehousing is ideal for industries with predictable demand and streamlined supply chains, such as automotive and manufacturing, where minimizing inventory holding costs is critical. On-Demand warehousing suits e-commerce, retail, and seasonal businesses that require flexible storage capacity to handle fluctuating order volumes and rapid fulfillment. The choice between Just-in-Time and On-Demand warehousing hinges on an industry's need for inventory control precision versus scalability and responsiveness to market dynamics.

Future Trends in Warehousing Strategies

Future trends in warehousing strategies emphasize the integration of Just-in-Time (JIT) and On-Demand warehousing models to enhance operational flexibility and reduce inventory costs. Advanced AI-driven analytics and IoT technologies enable real-time demand forecasting, optimizing storage space and improving supply chain responsiveness. The shift towards sustainable practices and automated warehouse management systems further refines inventory accuracy and accelerates order fulfillment processes.

Related Important Terms

Elastic Warehousing

Elastic warehousing leverages flexible storage capacity to match fluctuating inventory demands, offering a scalable solution that reduces overhead compared to traditional Just-in-Time systems. This approach allows businesses to efficiently manage peak seasons and unexpected surges by dynamically adjusting warehouse space and resources in real-time.

Micro-Fulfillment Centers

Micro-fulfillment centers enhance just-in-time warehousing by enabling rapid replenishment and minimizing inventory holding costs through localized storage and automation. On-demand warehousing leverages these micro-fulfillment hubs to provide flexible, scalable storage solutions that optimize last-mile delivery and improve order fulfillment speed.

Inventory Pooled Storage

Inventory pooled storage in just-in-time warehousing reduces holding costs by synchronizing product arrivals with production schedules, minimizing stock levels while ensuring timely availability. On-demand warehousing leverages inventory pooled storage to enable flexible, scalable space utilization, allowing businesses to respond quickly to fluctuating demand without long-term commitments.

Capacity-as-a-Service

Just-in-Time warehousing minimizes inventory storage by synchronizing supply arrivals precisely with production schedules, reducing overhead and enhancing operational efficiency. On-Demand Warehousing, as a form of Capacity-as-a-Service, offers flexible, scalable storage solutions that adapt to fluctuating demand, optimizing warehouse utilization and cost management.

Dynamic Slotting

Dynamic slotting in Just-in-Time warehousing optimizes inventory placement by continuously adjusting storage locations based on real-time demand patterns, reducing picking times and increasing throughput efficiency. In contrast, On-Demand warehousing uses dynamic slotting to flexibly allocate space for fluctuating inventory volumes, enhancing space utilization and responsiveness to unexpected order surges.

Real-Time Inventory Visibility

Just-in-Time warehousing relies heavily on precise real-time inventory visibility to synchronize stock levels with production schedules, minimizing holding costs and reducing waste. On-Demand warehousing leverages real-time inventory data to dynamically allocate storage space and fulfill orders quickly, enhancing flexibility and responsiveness in supply chain management.

Uberization of Warehousing

The Uberization of warehousing revolutionizes inventory management by enabling businesses to access on-demand warehousing spaces with the flexibility of Just-in-Time (JIT) delivery principles, reducing storage costs and improving supply chain responsiveness. This model leverages digital platforms to match excess warehouse capacity with real-time demand, facilitating efficient asset utilization and scalable logistics solutions.

Shared Warehousing Ecosystem

The shared warehousing ecosystem enhances operational efficiency by integrating Just-in-Time inventory strategies with On-Demand warehousing solutions, enabling businesses to optimize storage costs and reduce lead times. Leveraging real-time data analytics and scalable storage capacity within shared warehousing networks supports agile supply chain management and dynamic inventory allocation.

API-Driven Fulfillment

API-driven fulfillment in Just-in-Time warehousing enables seamless integration with inventory management systems, ensuring real-time stock updates and reducing storage costs by delivering goods precisely when needed. On-Demand Warehousing leverages APIs to dynamically allocate warehouse space and manage order processing, enhancing flexibility and scalability for fluctuating demand without long-term commitments.

Flexspace Optimization

Just-in-Time warehousing minimizes inventory holding by synchronizing deliveries closely with production schedules, enhancing Flexspace Optimization through precise spatial planning and reduced storage needs. On-Demand warehousing leverages flexible, scalable storage solutions that dynamically adjust to fluctuating inventory levels, maximizing space utilization and operational efficiency in real time.

Just-in-Time vs On-Demand Warehousing Infographic

industrydif.com

industrydif.com