Manual picking relies on warehouse workers physically locating and retrieving products, which can increase the risk of errors and slow down the order fulfillment process. Pick-to-light systems use illuminated displays to guide pickers to precise locations, improving accuracy and boosting efficiency by reducing search time. Implementing pick-to-light technology often results in higher productivity and lower labor costs compared to traditional manual picking methods.

Table of Comparison

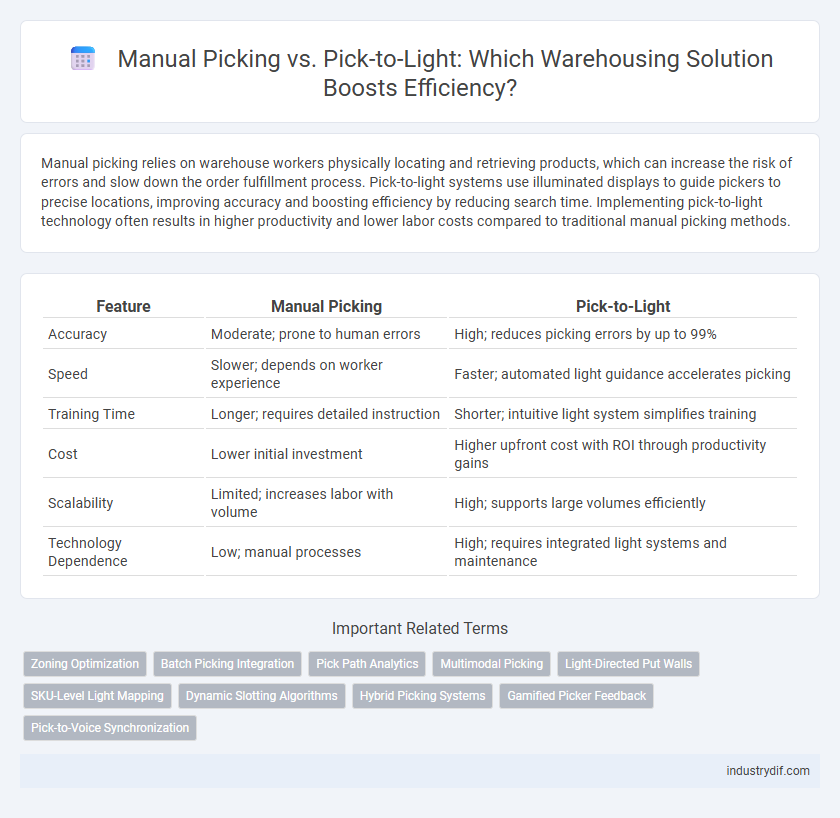

| Feature | Manual Picking | Pick-to-Light |

|---|---|---|

| Accuracy | Moderate; prone to human errors | High; reduces picking errors by up to 99% |

| Speed | Slower; depends on worker experience | Faster; automated light guidance accelerates picking |

| Training Time | Longer; requires detailed instruction | Shorter; intuitive light system simplifies training |

| Cost | Lower initial investment | Higher upfront cost with ROI through productivity gains |

| Scalability | Limited; increases labor with volume | High; supports large volumes efficiently |

| Technology Dependence | Low; manual processes | High; requires integrated light systems and maintenance |

Introduction to Warehousing Picking Methods

Warehousing picking methods significantly impact order fulfillment efficiency and accuracy, with manual picking involving workers selecting items by hand from storage locations. Pick-to-light systems enhance productivity by using light indicators to guide operators to the correct items, reducing errors and speeding up the process. Comparing these methods highlights the trade-offs between labor intensity and technological investment in warehouse operations.

What is Manual Picking?

Manual picking in warehousing refers to the process where workers physically locate and retrieve products from storage shelves using handheld lists or mobile devices. This traditional method relies heavily on human accuracy and speed, often leading to higher error rates and slower order fulfillment compared to automated systems. Manual picking remains prevalent in small to medium-sized operations where investment in technology like Pick-to-Light systems is limited.

What is Pick-to-Light Technology?

Pick-to-Light technology is an advanced warehouse order picking system that uses illuminated displays to guide operators to the exact item location, improving accuracy and efficiency. This system reduces human errors common in manual picking by providing real-time visual cues and quantity confirmation through LED lights and digital displays. Implementing Pick-to-Light can lead to significant productivity gains, faster order fulfillment, and streamlined inventory management.

Key Differences Between Manual Picking and Pick-to-Light

Manual picking relies on paper-based or handheld device instructions, resulting in higher error rates and slower order fulfillment, whereas Pick-to-Light systems use illuminated displays to guide operators, increasing accuracy and speed. Manual picking demands extensive training and physical effort, while Pick-to-Light reduces cognitive load by visually directing workers to precise pick locations. The integration of Pick-to-Light enhances real-time inventory tracking and reduces labor costs, setting it apart as a more efficient solution for high-volume warehouses.

Efficiency Comparison: Manual Picking vs Pick-to-Light

Manual picking relies heavily on human accuracy and speed, often resulting in variable efficiency and higher error rates during order fulfillment. Pick-to-Light systems enhance efficiency by guiding workers with visual cues, significantly reducing picking errors and increasing throughput by up to 40%. Implementing Pick-to-Light technology optimizes warehouse operations, leading to faster order processing and improved overall productivity.

Accuracy and Error Rates in Picking Systems

Manual picking systems typically exhibit higher error rates, with accuracy often below 95%, due to human factors such as fatigue and misreading labels. In contrast, Pick-to-Light technology enhances accuracy by guiding operators with illuminated indicators, achieving error rates as low as 1% and increasing overall picking precision. The integration of Pick-to-Light systems significantly reduces mispicks, improving order fulfillment accuracy and operational efficiency in warehousing environments.

Labor Costs and Workforce Considerations

Manual picking in warehousing typically incurs higher labor costs due to increased time spent per order and reliance on worker accuracy, which can lead to inefficiencies and errors. Pick-to-Light technology reduces labor expenses by speeding up item retrieval and minimizing mistakes, allowing for a leaner, more productive workforce. Workforce considerations include training complexity and employee adaptability, with pick-to-light systems often requiring less intensive training and supporting improved ergonomic conditions.

Scalability and Integration with Warehouse Management Systems

Manual picking offers limited scalability due to its reliance on human labor, which can slow down order fulfillment during peak periods. Pick-to-Light systems enhance scalability by streamlining the picking process through visual indicators, significantly reducing errors and increasing speed. Integration with Warehouse Management Systems (WMS) is more seamless in Pick-to-Light solutions, enabling real-time inventory updates and better workflow coordination compared to manual picking.

Implementation Challenges and Best Practices

Manual picking in warehousing faces challenges such as increased labor costs, higher error rates, and slower order fulfillment, especially during peak periods. Implementing Pick-to-Light systems requires careful integration with existing warehouse management software, employee training, and upfront investment in technology, but it can drastically improve accuracy and speed. Best practices include conducting a detailed workflow analysis before deployment, gradual system rollouts, and continuous performance monitoring to address issues promptly.

Choosing the Right Picking Solution for Your Warehouse

Choosing the right picking solution for your warehouse depends on factors like order volume, accuracy requirements, and budget constraints. Manual picking offers flexibility and low upfront costs, ideal for smaller operations with variable SKUs, while Pick-to-Light systems enhance speed and accuracy through visual cues, boosting productivity in high-density, high-throughput environments. Evaluating your warehouse layout, labor availability, and integration capabilities ensures optimal order fulfillment and operational efficiency.

Related Important Terms

Zoning Optimization

Manual picking relies heavily on worker knowledge and physical zoning layouts to optimize travel paths, often resulting in slower order processing times. Pick-to-Light systems integrate with dynamic zoning technology, significantly enhancing accuracy and efficiency by guiding pickers directly to designated locations and reducing unnecessary movement.

Batch Picking Integration

Batch picking integration enhances efficiency in manual picking by allowing workers to collect multiple orders simultaneously, reducing travel time and increasing throughput. In pick-to-light systems, batch picking is seamlessly supported through visual cues that guide operators through optimized pick sequences, minimizing errors and accelerating order fulfillment.

Pick Path Analytics

Pick-to-Light systems enhance warehousing efficiency by providing real-time visual cues that optimize pick paths, reducing travel time and errors compared to manual picking reliance on memory and paper lists. Detailed pick path analytics from Pick-to-Light technology allow managers to identify bottlenecks, streamline workflows, and improve overall inventory accuracy and order fulfillment speed.

Multimodal Picking

Multimodal picking combines manual picking and pick-to-light technologies to enhance warehouse efficiency by reducing errors and increasing speed in order fulfillment. Integrating visual cues from pick-to-light systems with human decision-making optimizes complex workflows and boosts overall productivity in diverse inventory environments.

Light-Directed Put Walls

Light-directed put walls enhance manual picking efficiency by visually guiding workers to specific locations for accurate item placement, reducing errors and increasing throughput. This technology integrates with warehouse management systems to streamline order fulfillment, offering a scalable alternative to traditional labor-intensive picking methods.

SKU-Level Light Mapping

Manual picking relies heavily on warehouse workers visually scanning and locating products without guided indicators, often leading to slower throughput and higher error rates especially with large SKU volumes. Pick-to-Light systems enhance SKU-level light mapping by directing operators with illuminated displays at specific bin locations, increasing picking accuracy, speed, and overall warehouse efficiency.

Dynamic Slotting Algorithms

Dynamic slotting algorithms optimize inventory placement by analyzing real-time order patterns and product velocity, enhancing manual picking efficiency through reduced travel time and improved picker productivity. In pick-to-light systems, these algorithms align optimal item locations with visual cues, further streamlining the picking process and minimizing errors.

Hybrid Picking Systems

Hybrid picking systems combine manual picking's flexibility with pick-to-light technology's speed and accuracy, enhancing warehouse efficiency and reducing errors. By integrating both methods, warehouses optimize item retrieval for varying order complexities and product types, balancing labor costs and throughput.

Gamified Picker Feedback

Manual picking relies heavily on worker intuition and repetitive tasks, often leading to inconsistencies and reduced engagement, while Pick-to-Light systems enhance accuracy and efficiency by guiding pickers with visual cues. Gamified picker feedback in Pick-to-Light setups boosts motivation and productivity by integrating real-time performance metrics and reward mechanisms, transforming routine picking into an interactive experience.

Pick-to-Voice Synchronization

Pick-to-Voice synchronization enhances order accuracy and efficiency by guiding warehouse operators through verbal instructions, reducing reliance on visual cues compared to Manual Picking. This technology integrates voice-directed workflows with real-time inventory data, streamlining picking processes and minimizing errors in complex warehouse environments.

Manual Picking vs Pick-to-Light Infographic

industrydif.com

industrydif.com