Manual sorting in warehousing relies on human workers to categorize and organize items, offering flexibility for handling irregular or fragile products. Robotic sortation systems provide faster processing speeds, increased accuracy, and reduced labor costs, making them ideal for high-volume operations. Integrating both methods can optimize efficiency by balancing human judgment with automated precision.

Table of Comparison

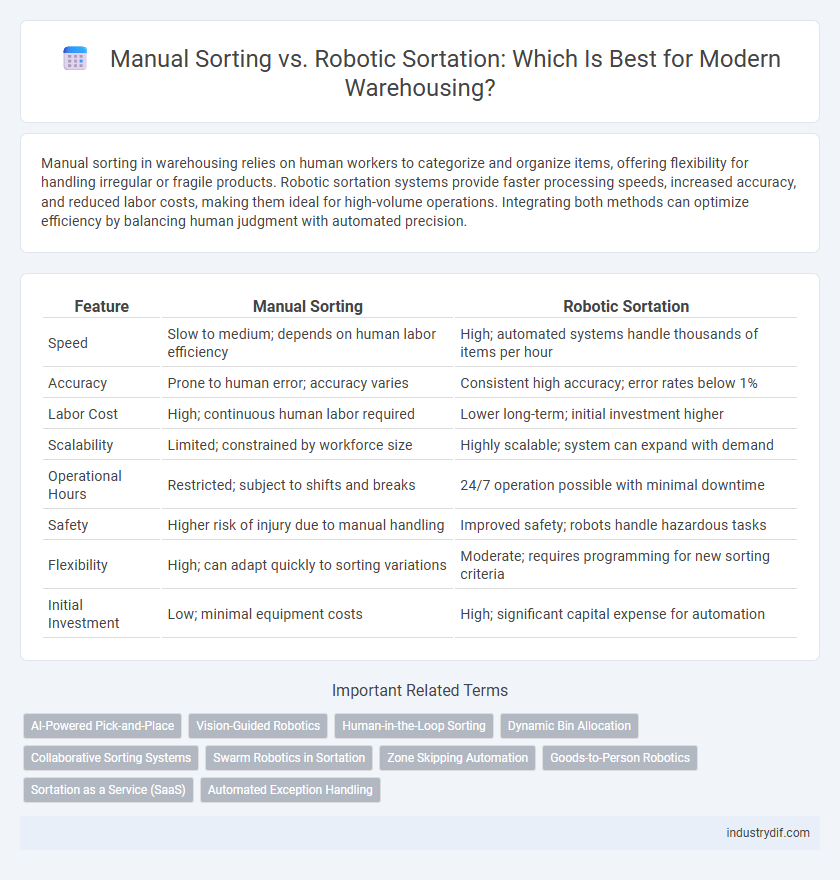

| Feature | Manual Sorting | Robotic Sortation |

|---|---|---|

| Speed | Slow to medium; depends on human labor efficiency | High; automated systems handle thousands of items per hour |

| Accuracy | Prone to human error; accuracy varies | Consistent high accuracy; error rates below 1% |

| Labor Cost | High; continuous human labor required | Lower long-term; initial investment higher |

| Scalability | Limited; constrained by workforce size | Highly scalable; system can expand with demand |

| Operational Hours | Restricted; subject to shifts and breaks | 24/7 operation possible with minimal downtime |

| Safety | Higher risk of injury due to manual handling | Improved safety; robots handle hazardous tasks |

| Flexibility | High; can adapt quickly to sorting variations | Moderate; requires programming for new sorting criteria |

| Initial Investment | Low; minimal equipment costs | High; significant capital expense for automation |

Introduction to Manual Sorting and Robotic Sortation

Manual sorting in warehousing involves human workers physically sorting items based on size, weight, or destination, enabling flexibility for handling diverse products but often limiting speed and scalability. Robotic sortation utilizes automated systems equipped with advanced sensors and AI algorithms to efficiently sort packages with high accuracy and speed, significantly enhancing throughput and reducing labor costs. Implementing robotic sortation can optimize operational workflows while manual sorting remains practical for complex or low-volume tasks requiring human judgment.

Key Differences Between Manual and Robotic Sorting

Manual sorting relies on human labor to identify, categorize, and organize products, offering flexibility in handling diverse items but with slower throughput and higher error rates. Robotic sortation utilizes automated systems and AI-driven machines to quickly and accurately sort large volumes of goods, improving efficiency and consistency while requiring significant initial investment. The key differences lie in speed, accuracy, scalability, and operational costs, with robotics excelling in high-volume environments and manual sorting suited for complex or variable item handling.

Efficiency Comparison: Labor vs Automation

Manual sorting in warehousing relies heavily on human labor, which can lead to variability in speed and accuracy due to fatigue and human error, often resulting in lower throughput and higher operational costs. Robotic sortation systems leverage automation technology, delivering consistent high-speed sorting with precision, significantly reducing error rates and labor expenses while enabling scalable operations. Efficiency comparisons consistently show that robotic sortation outperforms manual sorting in productivity, cost savings, and adaptability to high-volume and complex inventory environments.

Accuracy and Error Rates in Sorting Systems

Manual sorting in warehousing often results in higher error rates due to human fatigue and variability, impacting overall accuracy in order fulfillment. Robotic sortation systems utilize advanced sensors and machine learning algorithms to achieve near-perfect accuracy, significantly reducing sorting errors and improving efficiency. Implementing robotic sortation can lower error rates by up to 99%, ensuring consistent product handling and enhanced inventory management.

Scalability and Flexibility in Warehouse Operations

Manual sorting offers flexibility in handling diverse product types without requiring significant upfront investment but faces scalability challenges during peak demand due to labor constraints. Robotic sortation systems provide high scalability by automating repetitive tasks and increasing throughput, enabling rapid adaptation to fluctuating order volumes. Integrating robotic sortation enhances operational efficiency and supports scalable growth, while maintaining some manual processes allows for flexibility in managing complex and variable inventory.

Cost Implications: Upfront and Long-Term Investments

Manual sorting requires lower upfront investment, making it accessible for small warehouses with limited budgets, but ongoing labor costs can accumulate significantly over time. Robotic sortation demands substantial initial capital expenditure on advanced machinery and software, yet it minimizes labor expenses and enhances efficiency, leading to reduced operational costs in the long run. Evaluating cost implications involves balancing immediate financial constraints against potential savings from increased automation and productivity in warehouse operations.

Safety Considerations: Human Workers vs Robots

Manual sorting in warehousing involves direct human interaction with products, which increases the risk of workplace injuries such as repetitive strain, cuts, and slips. Robotic sortation systems reduce these hazards by automating heavy lifting and repetitive tasks, thereby minimizing human exposure to physical strain and accidents. Implementing robotic technology enhances overall safety compliance and reduces workers' compensation claims associated with manual handling.

Speed and Throughput Analysis

Manual sorting relies heavily on human labor, resulting in variable throughput rates typically ranging from 100 to 300 items per hour depending on worker efficiency and fatigue levels. Robotic sortation systems consistently achieve higher speeds, processing up to 1,000 to 3,000 items per hour by utilizing automated conveyors and AI-powered sorting algorithms. This significant difference in throughput underscores the advantage of robotic solutions in high-volume warehousing environments seeking to optimize operational speed and accuracy.

Environmental Impact: Energy Use and Sustainability

Manual sorting in warehousing relies heavily on human labor, resulting in variable energy consumption primarily tied to lighting and HVAC systems. Robotic sortation systems, powered by advanced automation technology, offer consistent and optimized energy use, often integrating energy-efficient motors and smart power management, reducing overall carbon footprint. Embracing robotic sortation enhances sustainability efforts by minimizing energy waste and supporting eco-friendly warehouse operations.

Future Trends in Warehouse Sortation Technologies

Emerging warehouse sortation technologies emphasize the integration of advanced robotics equipped with AI-powered vision systems, enabling faster and more accurate item identification compared to traditional manual sorting methods. Automation through smart robotics reduces labor costs and minimizes human error while enhancing scalability to meet increasing e-commerce demands. Future trends indicate a shift toward hybrid systems combining human oversight with robotic precision, driven by advancements in machine learning and real-time data analytics for optimized warehouse workflow efficiency.

Related Important Terms

AI-Powered Pick-and-Place

AI-powered pick-and-place systems in warehousing significantly enhance robotic sortation by increasing accuracy and speed compared to manual sorting methods. These advanced robots use machine learning algorithms and computer vision to identify, handle, and sort diverse products efficiently, reducing human error and operational costs.

Vision-Guided Robotics

Vision-guided robotics in warehousing dramatically enhances sorting accuracy and speed by utilizing advanced cameras and AI algorithms to identify, categorize, and route items more efficiently than manual sorting. Integrating these systems reduces human error, lowers labor costs, and improves throughput in high-volume distribution centers.

Human-in-the-Loop Sorting

Human-in-the-loop sorting in warehousing integrates manual sorting accuracy with robotic efficiency, enabling real-time human intervention to handle exceptions and ensure quality control. This hybrid approach optimizes operational flexibility and reduces sorting errors compared to fully automated systems, enhancing overall warehouse productivity.

Dynamic Bin Allocation

Dynamic bin allocation in manual sorting relies heavily on worker expertise and real-time decision-making, often resulting in varied efficiency and increased error rates. Robotic sortation systems utilize AI-driven dynamic bin allocation algorithms that optimize bin usage in real-time, significantly enhancing throughput accuracy and reducing labor costs.

Collaborative Sorting Systems

Collaborative sorting systems integrate manual sorting flexibility with robotic precision, enhancing warehouse efficiency by reducing errors and increasing throughput. These systems enable real-time human-machine interaction, optimizing workflow and adapting to varying order complexities in dynamic fulfillment environments.

Swarm Robotics in Sortation

Swarm robotics in sortation leverages a collective system of small, autonomous robots to increase efficiency and flexibility in warehouse operations, outperforming traditional manual sorting by reducing human error and labor costs. These robots dynamically communicate and coordinate tasks, enabling scalable, adaptive sorting processes that optimize throughput and minimize downtime.

Zone Skipping Automation

Zone skipping automation in warehousing enhances efficiency by integrating robotic sortation systems that bypass intermediate sorting zones, reducing handling times compared to manual sorting. These automated solutions improve accuracy and throughput while minimizing labor costs and operational errors in distribution centers.

Goods-to-Person Robotics

Goods-to-person robotics in warehousing significantly enhances sorting efficiency by minimizing human error and increasing throughput compared to manual sorting methods. This technology enables automated retrieval and precise delivery of items to workers, streamlining order fulfillment and reducing labor costs.

Sortation as a Service (SaaS)

Sortation as a Service (SaaS) leverages advanced robotic sortation systems to enhance accuracy and throughput in warehousing operations compared to traditional manual sorting methods. Integrating SaaS solutions reduces labor costs, minimizes errors, and scales efficiently, optimizing inventory management and order fulfillment processes.

Automated Exception Handling

Automated exception handling in robotic sortation significantly reduces errors and processing time compared to manual sorting by instantly identifying and rerouting irregular or damaged items using advanced sensors and AI algorithms. This technology enhances warehouse efficiency and accuracy, minimizing human intervention and operational disruptions.

Manual Sorting vs Robotic Sortation Infographic

industrydif.com

industrydif.com