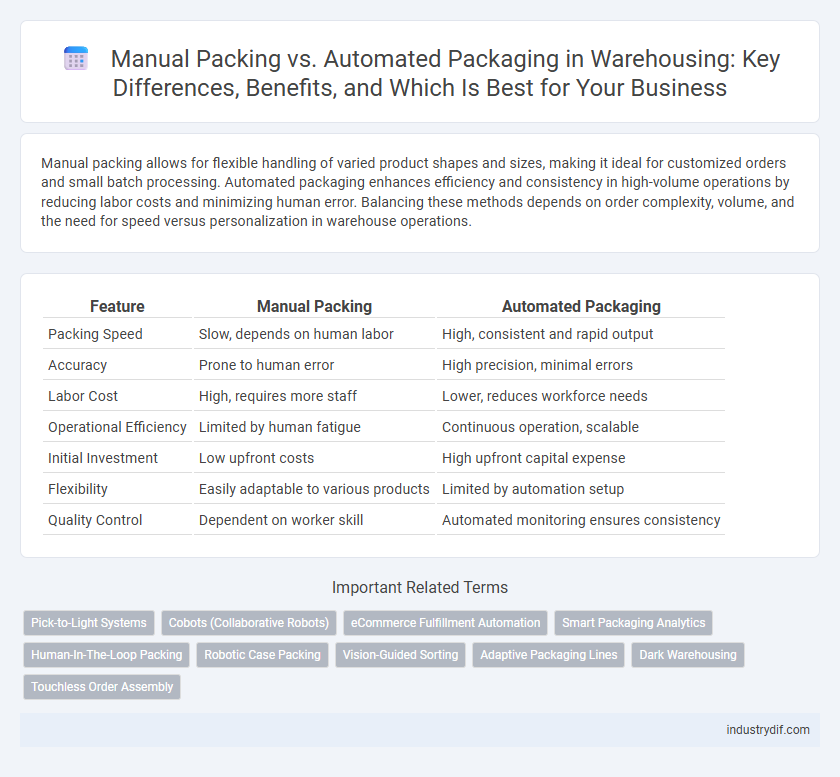

Manual packing allows for flexible handling of varied product shapes and sizes, making it ideal for customized orders and small batch processing. Automated packaging enhances efficiency and consistency in high-volume operations by reducing labor costs and minimizing human error. Balancing these methods depends on order complexity, volume, and the need for speed versus personalization in warehouse operations.

Table of Comparison

| Feature | Manual Packing | Automated Packaging |

|---|---|---|

| Packing Speed | Slow, depends on human labor | High, consistent and rapid output |

| Accuracy | Prone to human error | High precision, minimal errors |

| Labor Cost | High, requires more staff | Lower, reduces workforce needs |

| Operational Efficiency | Limited by human fatigue | Continuous operation, scalable |

| Initial Investment | Low upfront costs | High upfront capital expense |

| Flexibility | Easily adaptable to various products | Limited by automation setup |

| Quality Control | Dependent on worker skill | Automated monitoring ensures consistency |

Overview of Manual Packing and Automated Packaging

Manual packing in warehousing relies on human labor for sorting, assembling, and securing products into packages, allowing flexibility and customization for varied product types. Automated packaging utilizes machines and robotics to streamline the packing process, increasing efficiency, consistency, and throughput in high-volume operations. Both methods impact operational costs, accuracy, and scalability depending on the warehouse's size and product handling requirements.

Key Differences Between Manual and Automated Processes

Manual packing in warehousing involves human labor for sorting, assembling, and sealing products, which offers flexibility but limits speed and scalability. Automated packaging uses machinery such as conveyor systems, robotic arms, and automated sealers to increase throughput, consistency, and accuracy while reducing labor costs. Key differences include efficiency rates, error margins, operational costs, and adaptability to product variations.

Cost Comparison: Labor vs Technology Investment

Manual packing incurs higher ongoing labor costs due to wages, training, and potential errors, while automated packaging demands a significant upfront technology investment but reduces labor expenses over time. Automated systems improve packing speed and accuracy, leading to lower operational costs despite initial capital outlay. Companies must evaluate long-term cost savings from automation against continuous labor expenses in manual processes to determine the most economical warehousing solution.

Impact on Packing Speed and Efficiency

Manual packing typically results in slower packaging speeds due to human limitations in repetitive tasks, leading to inconsistent throughput rates. Automated packaging systems significantly enhance packing efficiency by maintaining continuous high-speed operations, reducing human error, and optimizing material usage. Warehouses adopting automated solutions often see a 30-50% increase in packing speed and improved overall productivity compared to manual methods.

Accuracy and Error Rate Analysis

Automated packaging systems significantly reduce error rates in warehousing operations by utilizing precise robotic controls and real-time data monitoring, ensuring consistent packing accuracy. Manual packing, while flexible, is more prone to human error such as incorrect item placement or labeling mistakes, leading to increased rework and inventory discrepancies. Analyzing error metrics shows that warehouses adopting automated packaging experience up to 70% fewer packing errors, directly improving order accuracy and customer satisfaction.

Labor Requirements and Workforce Implications

Manual packing demands a higher labor force with increased physical effort, often resulting in slower processing times and elevated risk of worker fatigue and injury. Automated packaging significantly reduces labor requirements by streamlining operations through machinery, enabling consistent output and minimizing human error. Workforce implications include a shift toward technical roles for machine operation and maintenance, requiring upskilling and potential workforce restructuring.

Scalability for Growing Warehousing Operations

Automated packaging systems offer superior scalability for growing warehousing operations by increasing throughput and reducing labor costs, enabling faster processing of larger order volumes. Manual packing, while flexible for small-scale or customized orders, often becomes a bottleneck as warehouse demands grow due to slower speeds and higher error rates. Investing in automation technology supports seamless expansion and operational efficiency essential for scalable warehousing growth.

Flexibility in Handling Diverse Product Types

Manual packing offers superior flexibility in handling diverse product types due to human adaptability in managing irregular shapes, sizes, and fragile items. Automated packaging systems excel in speed and consistency but may require extensive reprogramming to accommodate product variations. Choosing between manual and automated solutions depends on the product complexity and volume demands within warehousing operations.

Safety Considerations in Manual and Automated Systems

Manual packing poses higher safety risks due to repetitive motion injuries and potential exposure to sharp tools or heavy lifting, necessitating strict ergonomic practices and personal protective equipment. Automated packaging systems reduce physical strain and minimize human error but require robust safety protocols around machinery operation, including sensors, emergency stops, and regular maintenance to prevent accidents. Implementing a comprehensive safety management plan tailored to the specific packing environment significantly enhances worker protection in both manual and automated settings.

Environmental Impact and Sustainability Factors

Manual packing in warehousing often results in higher material waste and increased energy consumption due to less efficient processes and inconsistent packaging sizes, contributing to a larger carbon footprint. Automated packaging systems optimize material usage by precisely fitting products and reducing excess packaging, significantly lowering waste and energy expenditure. Implementing automated packaging technologies supports sustainability goals by minimizing resource consumption and enhancing operational efficiency in logistics.

Related Important Terms

Pick-to-Light Systems

Pick-to-Light systems enhance accuracy and speed in both manual packing and automated packaging by guiding operators with illuminated indicators for precise item selection. These systems reduce errors and improve productivity, making them essential for efficient warehouse order fulfillment processes.

Cobots (Collaborative Robots)

Cobots in warehousing enhance manual packing efficiency by combining human dexterity with robotic precision, significantly reducing errors and labor costs. Automated packaging solutions powered by cobots increase throughput, optimize space utilization, and improve safety by performing repetitive tasks alongside human workers.

eCommerce Fulfillment Automation

Manual packing in eCommerce fulfillment often leads to higher labor costs and increased risk of human error, slowing down order processing times. Automated packaging systems enhance efficiency by streamlining operations, reducing material waste, and enabling scalable throughput essential for high-volume warehouses.

Smart Packaging Analytics

Smart packaging analytics enhance efficiency by integrating real-time data from automated packaging systems to optimize packing workflows and reduce material waste. Manual packing lacks this advanced data insight, resulting in lower accuracy and slower response times in operational adjustments.

Human-In-The-Loop Packing

Human-in-the-loop packing integrates skilled workers with automated systems, enhancing accuracy and flexibility in warehousing operations by allowing real-time human intervention during packaging. This hybrid approach reduces errors and increases efficiency compared to fully manual or fully automated packaging processes, optimizing throughput and quality control.

Robotic Case Packing

Robotic case packing systems dramatically increase throughput and accuracy in warehousing by automating the placement of products into cases, reducing labor costs and minimizing human error compared to manual packing. These advanced robotics integrate with warehouse management systems (WMS) to optimize case configuration, improve packing density, and enhance overall operational efficiency.

Vision-Guided Sorting

Vision-guided sorting enhances automated packaging by utilizing advanced machine learning algorithms and optical sensors to identify, classify, and sort products with high precision, significantly reducing errors compared to manual packing. This technology increases throughput and consistency, optimizing warehouse operations and lowering labor costs by minimizing human intervention in the packaging process.

Adaptive Packaging Lines

Adaptive packaging lines optimize warehousing efficiency by seamlessly integrating manual packing flexibility with automated packaging speed, reducing labor costs and minimizing material waste. These systems leverage real-time data and AI-driven adjustments to customize packaging processes, enhancing throughput and ensuring precise order fulfillment in dynamic inventory environments.

Dark Warehousing

Dark warehousing leverages automated packaging systems to enhance efficiency, reduce labor costs, and minimize errors compared to traditional manual packing methods. Automated packaging in dark warehouses enables continuous 24/7 operation with advanced robotics and AI-driven sorting, optimizing space utilization and throughput rates.

Touchless Order Assembly

Touchless order assembly in warehousing significantly reduces human contact by utilizing automated packaging systems that enhance accuracy and speed while minimizing contamination risks. Manual packing, although flexible for customized orders, often slows operations and increases error rates compared to the efficiency and consistency of automated solutions.

Manual Packing vs Automated Packaging Infographic

industrydif.com

industrydif.com