Pallet racking systems provide robust storage solutions ideal for heavy and bulky items, offering easy access and high visibility, which improves inventory management and retrieval speed. Mobile shelving maximizes warehouse space by eliminating fixed aisles, allowing for compact storage configurations that can be moved to create access only where needed. Choosing between pallet racking and mobile shelving depends on storage density requirements, item size, and frequency of access to optimize warehouse efficiency.

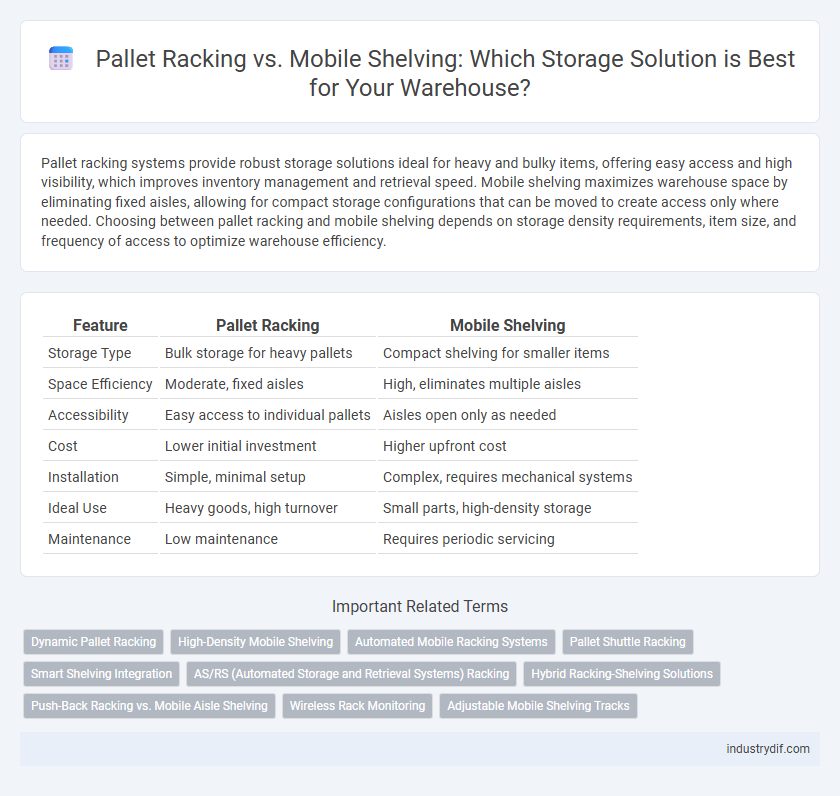

Table of Comparison

| Feature | Pallet Racking | Mobile Shelving |

|---|---|---|

| Storage Type | Bulk storage for heavy pallets | Compact shelving for smaller items |

| Space Efficiency | Moderate, fixed aisles | High, eliminates multiple aisles |

| Accessibility | Easy access to individual pallets | Aisles open only as needed |

| Cost | Lower initial investment | Higher upfront cost |

| Installation | Simple, minimal setup | Complex, requires mechanical systems |

| Ideal Use | Heavy goods, high turnover | Small parts, high-density storage |

| Maintenance | Low maintenance | Requires periodic servicing |

Introduction to Pallet Racking and Mobile Shelving

Pallet racking systems provide high-density storage solutions designed to hold heavy pallets in warehouses, optimizing vertical space and allowing for easy access with forklifts. Mobile shelving offers compact, floor-level storage units mounted on tracks, significantly increasing storage capacity in smaller footprints by eliminating fixed aisles. Both systems enhance warehouse efficiency but cater to different storage needs based on inventory type and space constraints.

Key Differences Between Pallet Racking and Mobile Shelving

Pallet racking offers high capacity and easy access for heavy, bulky goods with fixed shelving units designed for forklifts, while mobile shelving maximizes floor space by compactly storing items on movable carriages. Pallet racking systems are ideal for warehouses with wide aisles and frequent forklift traffic, whereas mobile shelving suits environments requiring dense storage and infrequent access. The choice depends on operational needs such as inventory type, space constraints, and retrieval frequency.

Space Optimization: Pallet Racking vs Mobile Shelving

Pallet racking maximizes vertical storage by accommodating large pallets and heavy goods, making it ideal for warehouses with high ceilings and heavy inventory. Mobile shelving offers superior floor space optimization by eliminating fixed aisles, enabling compact storage with easy access through movable units. Choosing between pallet racking and mobile shelving depends on the type of inventory and the warehouse's spatial constraints for optimal space utilization.

Load Capacity and Weight Distribution

Pallet racking systems typically support heavier loads, ranging from 1,000 to 5,000 kilograms per level, making them ideal for storing bulkier, palletized goods. Mobile shelving offers efficient space utilization with load capacities between 150 to 400 kilograms per shelf, optimized for smaller, lighter inventory with evenly distributed weight. Proper weight distribution in pallet racking reduces rack deflection and enhances structural integrity, while mobile shelving relies on balanced load placement to ensure smooth mobility and prevent operational hazards.

Cost Comparison: Initial Investment and Maintenance

Pallet racking systems typically require a higher initial investment due to the need for heavy-duty materials and installation costs, whereas mobile shelving offers a lower upfront expense by maximizing storage density within smaller footprints. Maintenance costs for pallet racking remain steady and involve routine inspections and occasional repairs of beams and uprights, while mobile shelving demands more frequent upkeep with mechanical components and track systems to ensure smooth operation. Choosing between the two depends on balancing the immediate capital outlay against long-term maintenance expenses and space optimization priorities.

Flexibility and Scalability in Storage Solutions

Pallet racking systems offer high scalability, allowing warehouses to efficiently adjust storage capacity by adding or removing racks according to inventory demands. Mobile shelving provides superior flexibility by enabling compact storage through movable units that maximize floor space utilization, ideal for dynamic environments with varying storage needs. Both solutions enhance operational efficiency, but pallet racking excels in heavy-load scalability, while mobile shelving optimizes space flexibility for smaller, diverse items.

Safety Considerations and Compliance

Pallet racking systems must adhere to strict load capacity limits and require regular inspections to prevent structural failures and ensure warehouse safety compliance with OSHA and ANSI standards. Mobile shelving offers enhanced space utilization but demands proper locking mechanisms and clear aisle protocols to avoid accidents during shelf movement, aligning with safety regulations like NFPA for fire egress. Both solutions necessitate employee training on safe handling practices and emergency procedures to minimize risks and maintain regulatory compliance in warehousing operations.

Installation and Operational Efficiency

Pallet racking installation typically requires a fixed layout with anchored frames, enabling rapid loading and unloading of large, heavy goods, optimizing space for bulk storage. Mobile shelving offers flexible aisle access by moving entire racks on tracks, increasing storage density and reducing footprint but demands precise installation to ensure smooth operation. Operational efficiency in pallet racking excels in high-throughput environments, while mobile shelving enhances space utilization and adaptability, particularly in warehouses with limited floor area.

Best Applications for Pallet Racking vs Mobile Shelving

Pallet racking systems excel in warehouses with high-volume, bulk storage needs and heavy-duty inventory, accommodating pallets with forklifts for efficient space utilization in large-scale operations. Mobile shelving optimizes compact spaces by maximizing storage density and enhancing accessibility, ideal for smaller items, archival storage, or environments requiring frequent inventory retrieval. Selecting between pallet racking and mobile shelving depends on inventory type, weight capacity, space constraints, and workflow requirements within the warehousing operation.

Choosing the Right System for Your Warehouse Needs

Pallet racking offers high-density storage for heavy and bulky items, optimizing vertical space to improve warehouse efficiency. Mobile shelving provides flexible, compact storage by eliminating fixed aisles, ideal for maximizing floor space in warehouses with limited square footage. Evaluating inventory types, storage capacity, and accessibility requirements ensures the selection of the right system tailored to specific warehouse operational needs.

Related Important Terms

Dynamic Pallet Racking

Dynamic pallet racking systems utilize gravity rollers or conveyors to enable first-in, first-out inventory flow, significantly increasing storage density and picking efficiency compared to traditional static racking. Unlike mobile shelving, which maximizes floor space by eliminating aisles, dynamic pallet racking optimizes inventory rotation and throughput for high-volume warehousing operations.

High-Density Mobile Shelving

High-density mobile shelving maximizes warehouse storage by eliminating fixed aisles, increasing storage capacity up to 85% compared to traditional pallet racking systems. This solution is ideal for facilities requiring compact, easily accessible storage with enhanced organization and faster retrieval times.

Automated Mobile Racking Systems

Automated Mobile Racking Systems maximize storage density by utilizing motorized racks that move along floor-mounted rails, significantly improving space utilization compared to traditional pallet racking and mobile shelving solutions. These systems integrate warehouse management software to enable precise inventory tracking and rapid, automated retrieval, enhancing operational efficiency in high-volume warehousing environments.

Pallet Shuttle Racking

Pallet Shuttle Racking enhances warehouse efficiency by automating the storage and retrieval of pallets within dense racking systems, reducing labor costs and increasing storage capacity compared to Mobile Shelving. This technology leverages a motorized shuttle to transport pallets across the racking lanes, optimizing space utilization and enabling faster order fulfillment in high-volume operations.

Smart Shelving Integration

Smart shelving integration enhances pallet racking systems by incorporating IoT sensors and automated inventory tracking, optimizing space utilization and improving real-time stock management. Mobile shelving solutions leverage smart technology for dynamic aisle creation and data-driven storage configurations, maximizing warehouse efficiency and accessibility.

AS/RS (Automated Storage and Retrieval Systems) Racking

AS/RS racking systems in warehousing offer higher storage density and faster retrieval speeds compared to traditional pallet racking and mobile shelving, maximizing space utilization and operational efficiency. Integrating advanced robotics and software controls, AS/RS racking streamlines inventory management by reducing labor costs and minimizing errors in high-throughput environments.

Hybrid Racking-Shelving Solutions

Hybrid racking-shelving solutions combine the high density and space efficiency of mobile shelving with the heavy load capacity and easy accessibility of pallet racking, optimizing warehouse storage and retrieval workflows. These systems enhance inventory management by enabling flexible configuration, reducing aisle space, and maximizing cubic storage utilization in warehouses with varying product sizes and turnover rates.

Push-Back Racking vs. Mobile Aisle Shelving

Push-back racking offers dense storage by allowing multiple pallets to be stored on a single lane, utilizing gravity-fed movement for efficient stock rotation and reducing aisle space requirements. Mobile aisle shelving maximizes floor space by enabling entire shelving units to move on tracks, creating a single accessible aisle and enhancing inventory accessibility while minimizing warehouse footprint.

Wireless Rack Monitoring

Wireless rack monitoring enhances pallet racking systems by providing real-time data on load weight, occupancy, and structural integrity, optimizing inventory management and safety compliance. Mobile shelving benefits from wireless sensors that track space utilization and movement patterns, facilitating efficient access and dynamic storage solutions.

Adjustable Mobile Shelving Tracks

Adjustable mobile shelving tracks maximize warehouse storage efficiency by enabling flexible aisle widths and reconfigurable shelving units, allowing rapid adaptation to changing inventory sizes and volume. Compared to static pallet racking, this system enhances space utilization by compacting storage aisles and facilitating easier access to stored items, optimizing both footprint and operational workflow.

Pallet Racking vs Mobile Shelving Infographic

industrydif.com

industrydif.com