Pick and Pack is a traditional warehousing method where workers manually select and package items based on order lists, offering flexibility for varied product types but slower processing times. Pick-to-Light systems enhance efficiency by using illuminated displays to guide operators to the correct locations, reducing errors and speeding up order fulfillment. Choosing between Pick and Pack and Pick-to-Light depends on order volume, SKU complexity, and the need for accuracy in the fulfillment process.

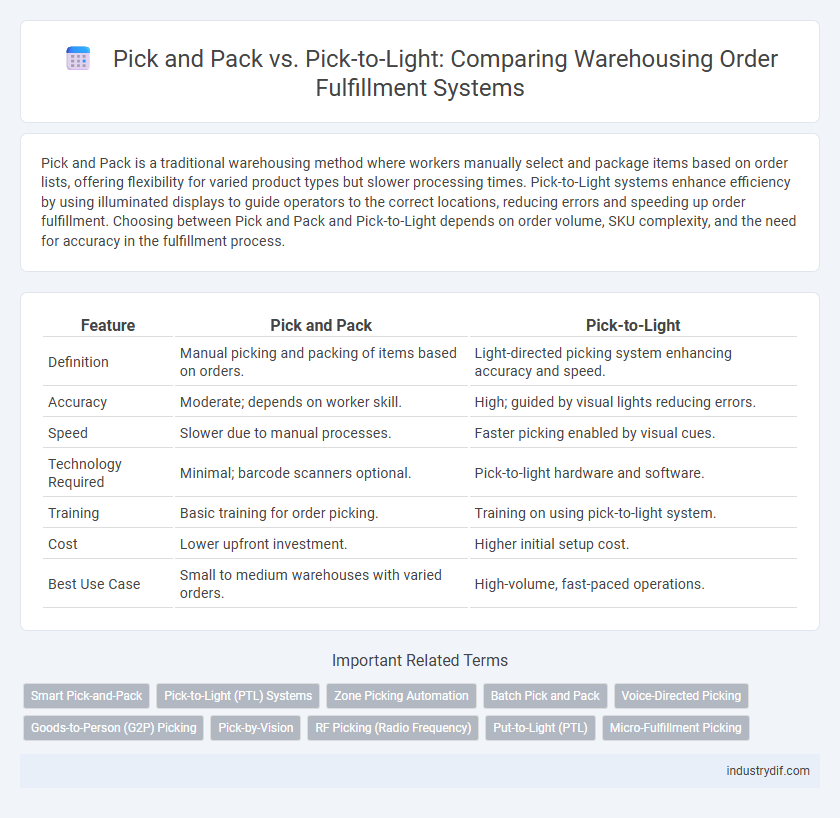

Table of Comparison

| Feature | Pick and Pack | Pick-to-Light |

|---|---|---|

| Definition | Manual picking and packing of items based on orders. | Light-directed picking system enhancing accuracy and speed. |

| Accuracy | Moderate; depends on worker skill. | High; guided by visual lights reducing errors. |

| Speed | Slower due to manual processes. | Faster picking enabled by visual cues. |

| Technology Required | Minimal; barcode scanners optional. | Pick-to-light hardware and software. |

| Training | Basic training for order picking. | Training on using pick-to-light system. |

| Cost | Lower upfront investment. | Higher initial setup cost. |

| Best Use Case | Small to medium warehouses with varied orders. | High-volume, fast-paced operations. |

Understanding Pick and Pack in Warehousing

Pick and Pack in warehousing involves selecting individual items from inventory and packaging them for shipment, optimizing order accuracy and efficiency. This method relies heavily on manual processes supported by barcode scanning or voice picking systems to reduce errors. Effective Pick and Pack operations require well-organized inventory layouts and trained personnel to meet high order fulfillment standards.

What is Pick-to-Light Technology?

Pick-to-Light technology is an automated warehouse picking system that uses illuminated indicators to guide workers to specific product locations, enhancing accuracy and speed. This system reduces errors by visually directing employees to pick exact quantities, streamlining order fulfillment processes compared to traditional pick and pack methods. Integration of Pick-to-Light technology improves inventory management, reduces training time, and accelerates throughput in high-volume distribution centers.

Key Differences Between Pick and Pack and Pick-to-Light

Pick and Pack involves manually selecting items from inventory and packing them for shipment, relying heavily on human accuracy and visual confirmation, whereas Pick-to-Light uses illuminated displays to guide workers to the correct locations and quantities, significantly reducing errors and increasing efficiency. Pick and Pack is labor-intensive and slower, suitable for smaller or less complex orders, while Pick-to-Light systems optimize order fulfillment speed and accuracy in high-volume warehouses. Integration of Pick-to-Light technology often results in improved inventory accuracy, reduced training time, and enhanced worker productivity compared to traditional Pick and Pack methods.

How Pick and Pack Works in Distribution Centers

Pick and Pack in distribution centers involves workers manually selecting items from storage locations based on customer orders and placing them into designated packing stations. This process relies heavily on accurate inventory management systems and clear order instructions to ensure correct item selection and packaging. Efficiency in Pick and Pack operations directly impacts order fulfillment speed and reduces errors in the supply chain.

Advantages of Pick-to-Light Systems

Pick-to-Light systems significantly improve order accuracy by providing visual cues that guide warehouse workers directly to the correct items, reducing picking errors compared to traditional Pick and Pack methods. These systems increase picking speed and throughput by minimizing the time spent searching for products, resulting in enhanced operational efficiency. Real-time inventory updates and streamlined workflow coordination also contribute to lower labor costs and improved overall warehouse productivity.

Efficiency Comparison: Pick and Pack vs Pick-to-Light

Pick-to-Light systems significantly enhance warehouse efficiency by reducing picking errors and accelerating order fulfillment compared to traditional Pick and Pack methods. The visual cues in Pick-to-Light streamline item selection, minimizing labor time and improving accuracy in high-volume operations. While Pick and Pack relies on manual identification and sorting, Pick-to-Light boosts productivity by integrating real-time guidance and reducing dependency on extensive training.

Implementation Costs: Pick and Pack Versus Pick-to-Light

Pick and Pack systems require lower initial investment due to minimal technology integration, relying primarily on manual labor and basic equipment like carts and bins. Pick-to-Light solutions involve higher upfront costs driven by the installation of electronic light displays and software, but can improve accuracy and speed, potentially reducing long-term labor expenses. Companies must evaluate their order volume and accuracy requirements to determine which method offers the best return on investment considering these implementation costs.

Common Use Cases in Warehousing

Pick and Pack is commonly used in e-commerce and retail warehouses where large volumes of small to medium-sized orders require manual picking and packing for shipment. Pick-to-Light systems are ideal in high-accuracy environments such as automotive or electronics warehouses, where speed and error reduction in picking numerous SKUs are critical. Both methods optimize order fulfillment but vary in technology integration and suitability based on order complexity and volume.

Accuracy and Error Rates in Order Fulfillment

Pick and Pack systems rely heavily on manual labor, often resulting in higher error rates due to mispicks or incorrect item placements. In contrast, Pick-to-Light technology utilizes visual cues to guide workers, significantly enhancing order accuracy and reducing mistakes. Studies reveal that Pick-to-Light can improve fulfillment accuracy by up to 99%, minimizing costly errors and boosting overall efficiency.

Choosing the Right Picking Method for Your Warehouse

Choosing the right picking method for your warehouse depends on factors such as order volume, accuracy requirements, and labor costs. Pick and Pack is ideal for small to medium-sized operations with diverse product assortments, leveraging manual picking and packing processes to maintain flexibility. Pick-to-Light systems enhance efficiency and reduce errors in high-volume, repetitive order fulfillment environments by guiding workers visually with lights at storage locations.

Related Important Terms

Smart Pick-and-Pack

Smart Pick-and-Pack leverages advanced automation and real-time inventory data to optimize order fulfillment, reducing errors and increasing throughput compared to traditional Pick and Pack methods. Unlike Pick-to-Light systems that rely on visual indicators for item selection, Smart Pick-and-Pack integrates AI-driven algorithms and IoT devices to enhance accuracy and efficiency in dynamic warehouse environments.

Pick-to-Light (PTL) Systems

Pick-to-Light (PTL) systems revolutionize warehousing efficiency by using illuminated displays to guide operators directly to product locations, reducing errors and speeding up order fulfillment. Unlike traditional Pick and Pack methods relying on paper or handheld devices, PTL optimizes picking accuracy, minimizes training time, and enhances real-time inventory management through seamless integration with warehouse management systems (WMS).

Zone Picking Automation

Zone picking automation enhances warehouse efficiency by dividing storage into distinct zones where pick-to-light systems guide workers to items quickly and accurately. Compared to traditional pick and pack methods, pick-to-light reduces errors and speeds up order fulfillment through real-time visual cues within each zone.

Batch Pick and Pack

Batch pick and pack streamlines order fulfillment by grouping multiple orders for simultaneous picking, reducing travel time and increasing efficiency compared to individual order processing. Unlike pick-to-light systems that rely on visual cues for single-item picking, batch pick and pack optimizes warehouse throughput by handling bulk item retrieval before sorting and packing.

Voice-Directed Picking

Voice-directed picking enhances accuracy and efficiency in warehousing by guiding workers through verbal instructions, reducing errors compared to traditional pick and pack systems that rely on manual scanning. Integrating voice technology with pick-to-light systems further optimizes order fulfillment speed and worker productivity by combining visual cues with hands-free operation.

Goods-to-Person (G2P) Picking

Pick and Pack involves manual item selection followed by packing, requiring significant walking and increasing errors, whereas Pick-to-Light systems utilize illuminated displays to guide workers in Goods-to-Person (G2P) picking, enhancing accuracy and reducing fulfillment time. G2P picking optimizes warehouse efficiency by delivering products directly to pickers, minimizing travel distance and enabling higher throughput in high-volume operations.

Pick-by-Vision

Pick-by-Vision technology enhances warehousing efficiency by using augmented reality glasses to guide workers through the picking process, reducing errors and increasing speed compared to traditional Pick and Pack or Pick-to-Light systems. This hands-free approach streamlines order fulfillment by providing real-time visual cues, allowing for faster and more accurate item selection in high-volume environments.

RF Picking (Radio Frequency)

RF Picking uses handheld devices to scan barcodes and guide operators through the warehouse, enhancing accuracy and real-time inventory updates in pick and pack processes. Pick-to-Light systems employ illuminated indicators at storage locations to speed item selection, but RF Picking offers greater flexibility and integration with dynamic warehouse management systems for complex order fulfillment.

Put-to-Light (PTL)

Put-to-Light (PTL) systems enhance warehousing efficiency by guiding operators to accurately place items into designated locations using illuminated indicators, reducing errors and speeding up put-away processes. Compared to traditional Pick and Pack or Pick-to-Light methods, PTL optimizes inventory management by streamlining the sorting and replenishment phases, particularly in high-volume distribution centers.

Micro-Fulfillment Picking

Pick and Pack workflows in micro-fulfillment centers involve manual item selection and packing, which can slow down order processing and increase labor costs. In contrast, Pick-to-Light systems use illuminated indicators to guide workers efficiently, reducing errors and accelerating picking speeds in compact, high-density storage environments.

Pick and Pack vs Pick-to-Light Infographic

industrydif.com

industrydif.com