Additive manufacturing creates objects by layering materials like plastics and metals, enabling rapid prototyping and complex designs in industrial production. Biofabrication extends this concept to living tissues, using cells and biomaterials to engineer biological structures for medical applications. While additive manufacturing focuses on mechanical components, biofabrication advances regenerative medicine through the creation of functional tissue constructs.

Table of Comparison

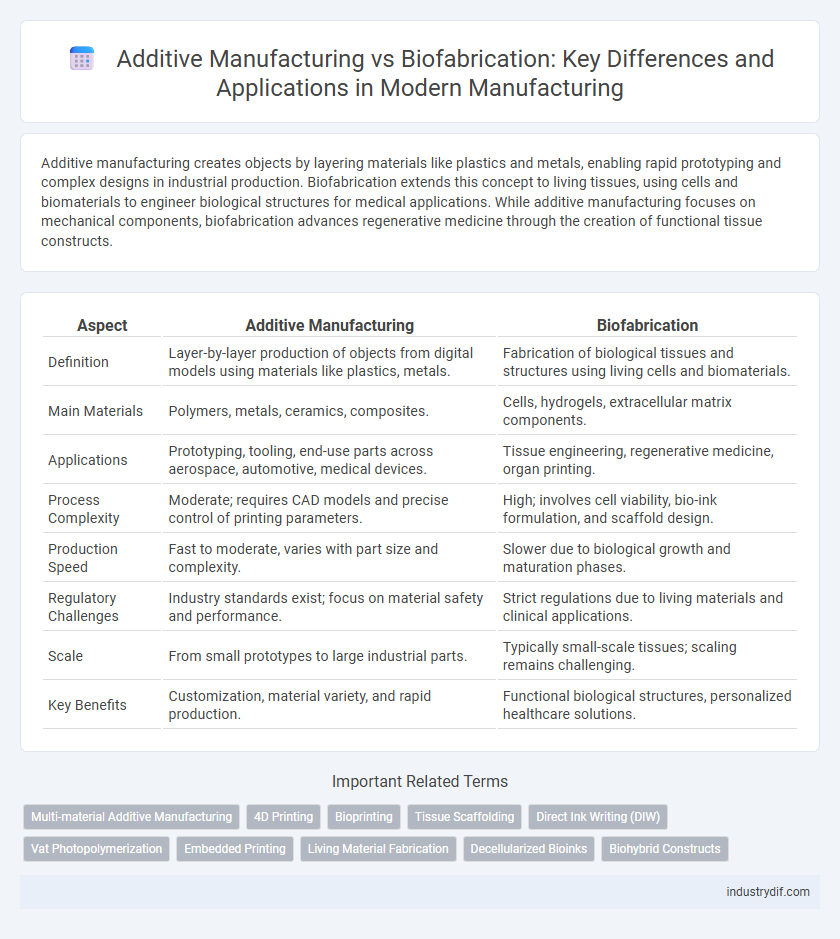

| Aspect | Additive Manufacturing | Biofabrication |

|---|---|---|

| Definition | Layer-by-layer production of objects from digital models using materials like plastics, metals. | Fabrication of biological tissues and structures using living cells and biomaterials. |

| Main Materials | Polymers, metals, ceramics, composites. | Cells, hydrogels, extracellular matrix components. |

| Applications | Prototyping, tooling, end-use parts across aerospace, automotive, medical devices. | Tissue engineering, regenerative medicine, organ printing. |

| Process Complexity | Moderate; requires CAD models and precise control of printing parameters. | High; involves cell viability, bio-ink formulation, and scaffold design. |

| Production Speed | Fast to moderate, varies with part size and complexity. | Slower due to biological growth and maturation phases. |

| Regulatory Challenges | Industry standards exist; focus on material safety and performance. | Strict regulations due to living materials and clinical applications. |

| Scale | From small prototypes to large industrial parts. | Typically small-scale tissues; scaling remains challenging. |

| Key Benefits | Customization, material variety, and rapid production. | Functional biological structures, personalized healthcare solutions. |

Introduction to Additive Manufacturing and Biofabrication

Additive Manufacturing (AM) involves layer-by-layer construction of objects using materials such as plastics, metals, and composites, enabling rapid prototyping and complex geometries with high precision. Biofabrication, a subset of AM, focuses on creating biological structures like tissues and organs by depositing living cells and biomaterials, pushing the boundaries of regenerative medicine. Both technologies leverage digital design and precise material placement, but biofabrication requires biocompatible materials and controlled environments to maintain cell viability during the manufacturing process.

Key Differences Between Additive Manufacturing and Biofabrication

Additive Manufacturing (AM) primarily builds three-dimensional objects layer by layer using materials such as plastics, metals, or composites for industrial applications, whereas Biofabrication specifically utilizes living cells and biomaterials to create tissue-like structures for medical and regenerative purposes. AM emphasizes precision in producing mechanical parts and prototypes, while Biofabrication focuses on biocompatibility and functionality for biological systems. Key differences include the choice of materials, process parameters, and end-use targets, with Biofabrication requiring sterile environments and specialized bio-inks to sustain cell viability.

Core Principles and Technologies Employed

Additive manufacturing utilizes layer-by-layer deposition of materials such as polymers, metals, or ceramics based on digital 3D models, employing technologies like fused deposition modeling (FDM), selective laser sintering (SLS), and stereolithography (SLA). Biofabrication integrates biological components such as cells, biomaterials, and growth factors to create tissue-like structures using bioprinting methods like inkjet bioprinting, extrusion-based bioprinting, and laser-assisted bioprinting. Core principles of additive manufacturing emphasize precision and material properties for functional parts, while biofabrication prioritizes cellular viability and biomimicry for regenerative medicine applications.

Materials Used in Additive Manufacturing vs Biofabrication

Additive manufacturing primarily utilizes materials such as thermoplastics, metals, ceramics, and composites, chosen for their structural integrity and mechanical properties suitable for industrial applications. Biofabrication employs biomaterials including hydrogels, collagen, alginate, and living cells, designed to mimic natural tissue properties and support cell growth. The fundamental difference lies in additive manufacturing's focus on synthetic, durable materials versus biofabrication's emphasis on biocompatible, bioactive substances.

Applications Across Industries

Additive manufacturing revolutionizes industries such as aerospace, automotive, and consumer goods by enabling rapid prototyping and complex part production with materials like plastics and metals. Biofabrication, primarily advancing healthcare and pharmaceuticals, focuses on creating living tissues and organs using bioprinting technologies for regenerative medicine and drug testing. Both technologies drive innovation by providing customized solutions, but additive manufacturing emphasizes structural components while biofabrication targets biological functionality.

Benefits and Limitations of Each Method

Additive manufacturing enables precise, customizable production with complex geometries and rapid prototyping, benefiting aerospace and automotive industries, yet it faces limitations in material diversity and speed for large-scale manufacturing. Biofabrication offers breakthroughs in tissue engineering and regenerative medicine through layer-by-layer deposition of living cells, promoting biocompatibility and functional biological structures but struggles with scalability, mechanical strength, and regulatory challenges. Both methods push innovation in manufacturing, balancing efficiencies against material constraints, application-specific demands, and technological maturity.

Innovations Driving Additive Manufacturing and Biofabrication

Innovations driving additive manufacturing include advancements in materials science, enabling the use of composites, metals, and polymers with enhanced mechanical properties and precision. In biofabrication, breakthroughs in bioprinting techniques and biomaterials facilitate the creation of complex tissue structures and functional organs with high cell viability and structural fidelity. Integration of AI and real-time monitoring systems accelerates customization and quality control in both additive manufacturing and biofabrication processes.

Regulatory and Quality Considerations

Regulatory frameworks for additive manufacturing emphasize compliance with material certification and process validation standards to ensure consistent product quality in industrial applications. Biofabrication faces stricter regulatory scrutiny due to the integration of living cells and biological materials, requiring rigorous biocompatibility testing and adherence to Good Manufacturing Practices (GMP) specific to tissue engineering. Quality considerations in additive manufacturing prioritize dimensional accuracy and repeatability, while biofabrication demands stringent control of cell viability, sterility, and functional performance to meet medical safety and efficacy standards.

Future Trends and Market Outlook

Additive manufacturing continues to evolve with innovations in materials and process automation, driving market growth projected to reach USD 35 billion by 2030, fueled by industries like aerospace and healthcare. Biofabrication is gaining momentum through advancements in bioprinting technology and tissue engineering, targeting regenerative medicine markets expected to exceed USD 10 billion within the next decade. Synergistic integration of these technologies is anticipated to revolutionize manufacturing paradigms, emphasizing customization, sustainability, and complex biologic structures.

Choosing the Right Process for Industry Needs

Additive manufacturing excels in producing complex, customized parts with high precision and scalability, making it ideal for aerospace and automotive industries. Biofabrication specializes in creating biological structures, such as tissue engineering and regenerative medicine, which demand biocompatible materials and controlled cellular environments. Selecting the right process depends on factors like material requirements, production volume, and application-specific demands, ensuring optimal efficiency and product performance.

Related Important Terms

Multi-material Additive Manufacturing

Multi-material additive manufacturing enables precise fabrication of complex structures by layering diverse materials with distinct properties, enhancing functional integration in sectors like aerospace and biomedical engineering. In contrast, biofabrication specifically focuses on printing living cells and biomaterials to create tissue-like constructs, pushing the boundaries of regenerative medicine and personalized healthcare.

4D Printing

4D printing in additive manufacturing integrates time-dependent transformations, enabling materials to change shape or properties in response to environmental stimuli, unlike traditional biofabrication which primarily focuses on creating static biological constructs. This technology enhances manufacturing flexibility by producing dynamic, adaptive components crucial for advanced aerospace, medical implants, and smart textiles industries.

Bioprinting

Bioprinting, a key technology in biofabrication, enables the precise layer-by-layer deposition of living cells and biomaterials to create functional tissue constructs, contrasting with traditional additive manufacturing that primarily uses metals, plastics, or ceramics for industrial parts production. Unlike conventional 3D printing techniques used in manufacturing, bioprinting requires specialized bioinks and controlled environments to maintain cell viability and support tissue growth for medical and regenerative applications.

Tissue Scaffolding

Additive manufacturing enables precise layer-by-layer construction of complex geometries for tissue scaffolding, enhancing mechanical strength and customizability. Biofabrication integrates living cells with biomaterials during scaffold formation to promote biological functionality and tissue regeneration.

Direct Ink Writing (DIW)

Direct Ink Writing (DIW) in additive manufacturing enables precise layer-by-layer construction of complex geometries using viscoelastic inks, offering versatility in material selection and structural customization. In biofabrication, DIW facilitates the deposition of bioinks containing living cells, supporting tissue engineering applications with enhanced cell viability and spatial resolution.

Vat Photopolymerization

Vat photopolymerization in additive manufacturing uses light to selectively cure liquid resin into solid parts with high precision and surface finish, making it ideal for intricate prototypes and complex geometries. Biofabrication adapts vat photopolymerization by employing biocompatible and cell-laden resins, enabling the creation of living tissue structures with fine microarchitectures for regenerative medicine applications.

Embedded Printing

Embedded printing in additive manufacturing enables precise layer-by-layer construction of complex structures within supportive materials, enhancing structural integrity and geometric complexity. Biofabrication leverages embedded printing to incorporate living cells and biomaterials into scaffolds, promoting tissue viability and functionality in regenerative medicine.

Living Material Fabrication

Additive manufacturing involves layer-by-layer construction using materials like metals and polymers, whereas biofabrication specifically focuses on living material fabrication by integrating cells, biomaterials, and growth factors to create functional biological structures. Living material fabrication advances regenerative medicine and tissue engineering by enabling the production of complex, viable tissues with precise cellular organization.

Decellularized Bioinks

Decellularized bioinks in biofabrication offer a cutting-edge approach by utilizing native extracellular matrix components to enhance cell compatibility and tissue regeneration, surpassing traditional additive manufacturing materials in biological functionality. Unlike conventional 3D printing methods, decellularized bioinks provide a biomimetic environment that supports complex tissue architecture and promotes vascularization crucial for advanced regenerative medicine applications.

Biohybrid Constructs

Biohybrid constructs in biofabrication integrate living cells with synthetic materials, enabling the creation of functional tissues that mimic natural biological structures, unlike traditional additive manufacturing which primarily focuses on layer-by-layer fabrication of inert materials. These biohybrid systems advance regenerative medicine by facilitating dynamic interactions between biological and engineered components, offering improved biocompatibility and functionality for tissue engineering applications.

Additive Manufacturing vs Biofabrication Infographic

industrydif.com

industrydif.com