Total Quality Management (TQM) emphasizes continuous improvement and employee involvement to enhance product quality and customer satisfaction in manufacturing processes. Predictive Maintenance utilizes data analytics and IoT sensors to monitor equipment health in real-time, preventing breakdowns and reducing downtime. Integrating TQM strategies with Predictive Maintenance technology leads to optimized production efficiency and sustained operational excellence.

Table of Comparison

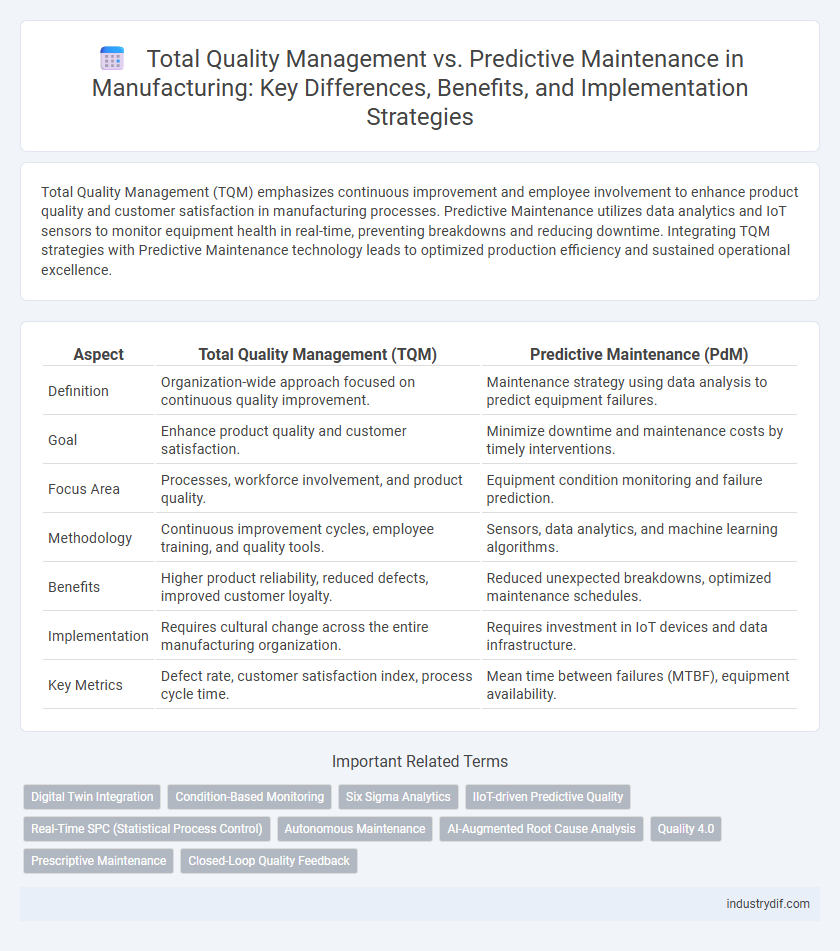

| Aspect | Total Quality Management (TQM) | Predictive Maintenance (PdM) |

|---|---|---|

| Definition | Organization-wide approach focused on continuous quality improvement. | Maintenance strategy using data analysis to predict equipment failures. |

| Goal | Enhance product quality and customer satisfaction. | Minimize downtime and maintenance costs by timely interventions. |

| Focus Area | Processes, workforce involvement, and product quality. | Equipment condition monitoring and failure prediction. |

| Methodology | Continuous improvement cycles, employee training, and quality tools. | Sensors, data analytics, and machine learning algorithms. |

| Benefits | Higher product reliability, reduced defects, improved customer loyalty. | Reduced unexpected breakdowns, optimized maintenance schedules. |

| Implementation | Requires cultural change across the entire manufacturing organization. | Requires investment in IoT devices and data infrastructure. |

| Key Metrics | Defect rate, customer satisfaction index, process cycle time. | Mean time between failures (MTBF), equipment availability. |

Understanding Total Quality Management in Manufacturing

Total Quality Management (TQM) in manufacturing emphasizes continuous improvement, customer satisfaction, and employee involvement to enhance product quality and operational efficiency. It integrates systematic processes such as quality control, process optimization, and supplier management to reduce defects and waste across the production cycle. Unlike Predictive Maintenance, which focuses on equipment reliability through data-driven maintenance forecasting, TQM provides a holistic approach to achieving overall manufacturing excellence.

Introduction to Predictive Maintenance

Predictive Maintenance uses real-time data and advanced analytics to foresee equipment failures, reducing unplanned downtime and optimizing maintenance schedules. Unlike Total Quality Management, which emphasizes continuous improvement in processes, Predictive Maintenance focuses specifically on machinery health monitoring through sensors and IoT technology. Implementing Predictive Maintenance enhances operational efficiency by enabling timely interventions based on condition-based insights rather than reactive repairs.

Core Principles of TQM versus Predictive Maintenance

Total Quality Management (TQM) centers on continuous improvement, customer focus, and employee involvement to enhance product quality and organizational processes. Predictive Maintenance relies on real-time data analysis and condition monitoring to anticipate equipment failures and optimize maintenance schedules. TQM emphasizes systemic quality enhancement across all operations, while Predictive Maintenance prioritizes minimizing downtime through proactive maintenance strategies.

Implementation Strategies: TQM vs Predictive Maintenance

Total Quality Management (TQM) implementation strategies focus on continuous process improvement, employee involvement, and customer satisfaction through systematic quality control methods and training programs. Predictive Maintenance strategies rely on advanced data analytics, real-time monitoring, and condition-based maintenance scheduling to preempt equipment failures and optimize asset longevity. Combining TQM's quality-centric approach with predictive maintenance's technology-driven insights leads to enhanced operational efficiency and reduced downtime in manufacturing environments.

Impact on Production Efficiency

Total Quality Management (TQM) enhances production efficiency by systematically eliminating defects and optimizing processes through continuous quality improvements. Predictive Maintenance improves equipment uptime and reduces unplanned downtime by using data analytics and IoT sensors to foresee machine failures before they occur. Integrating TQM with Predictive Maintenance results in streamlined workflows, higher product quality, and maximized operational productivity in manufacturing.

Data-Driven Decision Making: TQM and Predictive Maintenance

Total Quality Management (TQM) leverages data-driven decision making by systematically collecting and analyzing quality metrics to continuously improve manufacturing processes and product standards. Predictive Maintenance utilizes real-time sensor data and advanced analytics to forecast equipment failures, reducing downtime and optimizing maintenance schedules. Both approaches emphasize data integration and analysis to enhance operational efficiency and product reliability in manufacturing environments.

Cost Implications and ROI Comparison

Total Quality Management (TQM) reduces costs by minimizing defects and rework through comprehensive process improvements, leading to long-term ROI via enhanced product quality and customer satisfaction. Predictive Maintenance focuses on cost savings by preventing unexpected equipment failures and minimizing downtime, resulting in immediate ROI through optimized maintenance schedules and reduced repair expenses. Comparing both, TQM delivers sustained cost efficiency across manufacturing operations, while Predictive Maintenance offers rapid financial returns primarily in asset reliability and operational continuity.

Role of Technology in TQM and Predictive Maintenance

Technology in Total Quality Management (TQM) enhances data collection, process automation, and real-time monitoring to ensure consistent product quality and continuous improvement. Predictive Maintenance leverages IoT sensors, machine learning algorithms, and data analytics to forecast equipment failures, reducing downtime and maintenance costs. Integrating advanced technologies in both TQM and predictive maintenance drives operational efficiency and product reliability in manufacturing.

Case Studies: Success Stories in Manufacturing

Case studies in manufacturing reveal that Total Quality Management (TQM) enhances product consistency and reduces defects through systematic process improvements, exemplified by Toyota's implementation achieving significant waste reduction. Predictive Maintenance case studies, such as GE Aviation, demonstrate decreased equipment downtime and cost savings by utilizing sensor data and analytics to anticipate failures. These success stories underline how integrating TQM and Predictive Maintenance strategies boosts overall operational efficiency and product reliability in manufacturing settings.

Future Trends: Integrating TQM with Predictive Maintenance

Integrating Total Quality Management (TQM) with Predictive Maintenance leverages real-time data analytics and IoT sensors to enhance manufacturing efficiency and product quality simultaneously. Future trends emphasize AI-driven predictive models within TQM frameworks to proactively identify defects and equipment failures, minimizing downtime and reducing waste. This convergence supports continuous improvement cycles by aligning quality control with machine health monitoring, fostering smart, resilient manufacturing ecosystems.

Related Important Terms

Digital Twin Integration

Total Quality Management drives continuous improvement through data-driven quality control, while Predictive Maintenance leverages sensor data to anticipate equipment failures. Integrating Digital Twins enables real-time simulation and analysis, enhancing both quality assurance and maintenance precision by creating a virtual replica of manufacturing processes and machinery.

Condition-Based Monitoring

Total Quality Management (TQM) emphasizes continuous process improvement and customer satisfaction through systematic quality control, while Predictive Maintenance leverages Condition-Based Monitoring (CBM) using real-time sensor data and analytics to predict equipment failures and reduce downtime. Implementing CBM within Predictive Maintenance enhances asset reliability by detecting early signs of wear, which complements TQM's focus on maintaining high-quality manufacturing processes.

Six Sigma Analytics

Six Sigma analytics in Total Quality Management drives defect reduction and process optimization through data-driven methodologies, enhancing product consistency and customer satisfaction. Predictive maintenance leverages Six Sigma tools to forecast equipment failures, minimizing downtime and maximizing operational efficiency in manufacturing environments.

IIoT-driven Predictive Quality

IIoT-driven Predictive Quality integrates Total Quality Management principles by utilizing real-time sensor data and advanced analytics to anticipate defects and optimize production processes, thereby enhancing product consistency and reducing waste. Unlike traditional Predictive Maintenance focused on equipment health, this approach emphasizes proactive quality control, enabling manufacturers to detect variations early and maintain higher standards throughout the production lifecycle.

Real-Time SPC (Statistical Process Control)

Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction through employee involvement, while Predictive Maintenance leverages sensor data and machine learning to forecast equipment failures, minimizing downtime. Real-Time Statistical Process Control (SPC) integrates seamlessly with both methodologies by providing immediate data-driven insights into manufacturing processes, enabling proactive quality control and maintenance decisions that enhance operational efficiency.

Autonomous Maintenance

Total Quality Management (TQM) emphasizes continuous improvement and employee involvement to enhance product quality, while Predictive Maintenance uses data analytics and condition monitoring to prevent equipment failures. Autonomous Maintenance, a core pillar of Total Productive Maintenance, empowers operators to perform routine maintenance tasks, bridging the gap between TQM's quality focus and Predictive Maintenance's data-driven approach.

AI-Augmented Root Cause Analysis

AI-augmented root cause analysis enhances Total Quality Management by identifying defects and process inefficiencies with real-time data insights, while predictive maintenance uses similar AI techniques to forecast equipment failures and prevent downtime. Integrating these AI-driven strategies drives continuous improvement in manufacturing quality and operational reliability.

Quality 4.0

Total Quality Management in Manufacturing emphasizes continuous improvement and customer satisfaction through data-driven processes, while Predictive Maintenance leverages IoT sensors and AI analytics to foresee equipment failures, enhancing Quality 4.0 by integrating real-time quality control with proactive machine upkeep. This synergy reduces downtime, minimizes defects, and drives operational excellence in smart factories.

Prescriptive Maintenance

Prescriptive maintenance integrates Total Quality Management principles with predictive data analytics to optimize manufacturing equipment performance and reduce downtime by prescribing actionable maintenance tasks before failures occur. Leveraging real-time sensor data and advanced algorithms, prescriptive maintenance enhances decision-making processes, ensuring continuous quality improvement and operational efficiency.

Closed-Loop Quality Feedback

Total Quality Management (TQM) emphasizes continuous improvement through comprehensive closed-loop quality feedback systems that collect real-time data to identify defects and implement corrective actions, enhancing product reliability. Predictive Maintenance leverages sensor analytics within closed-loop feedback to anticipate equipment failures, minimizing downtime and supporting consistent production quality.

Total Quality Management vs Predictive Maintenance Infographic

industrydif.com

industrydif.com