The factory floor represents the physical hub of manufacturing where raw materials are transformed into finished products through machinery and human labor. The digital thread, on the other hand, creates a continuous data flow linking every stage of the product lifecycle, enhancing traceability, quality control, and decision-making. Integrating the factory floor with the digital thread enables real-time monitoring and predictive maintenance, driving efficiency and reducing downtime.

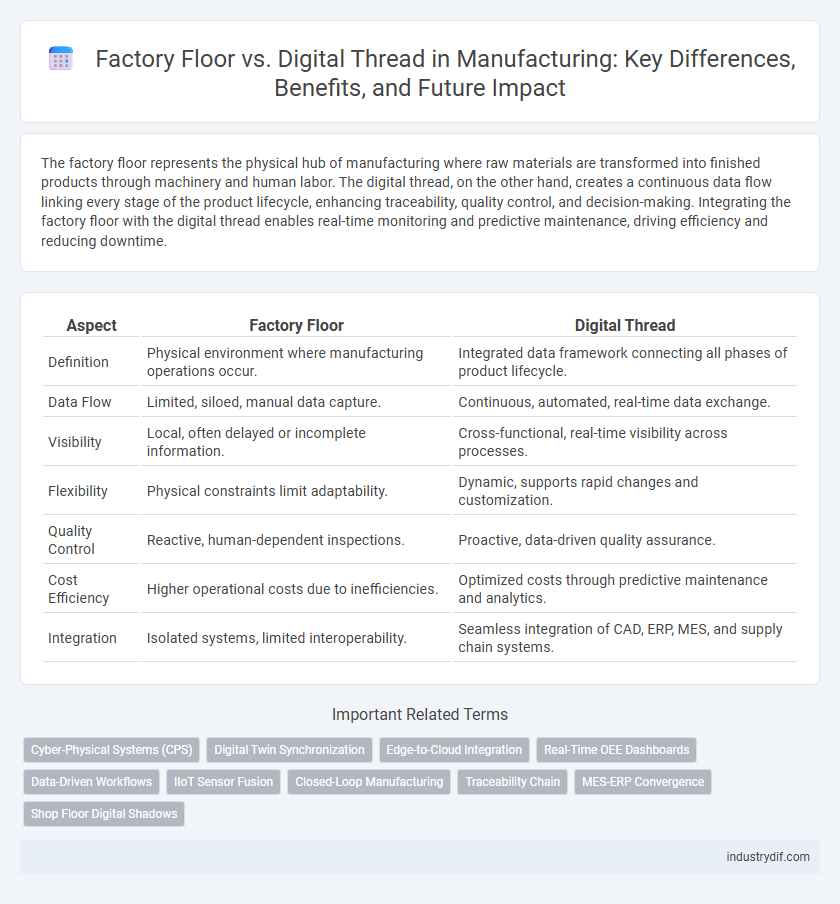

Table of Comparison

| Aspect | Factory Floor | Digital Thread |

|---|---|---|

| Definition | Physical environment where manufacturing operations occur. | Integrated data framework connecting all phases of product lifecycle. |

| Data Flow | Limited, siloed, manual data capture. | Continuous, automated, real-time data exchange. |

| Visibility | Local, often delayed or incomplete information. | Cross-functional, real-time visibility across processes. |

| Flexibility | Physical constraints limit adaptability. | Dynamic, supports rapid changes and customization. |

| Quality Control | Reactive, human-dependent inspections. | Proactive, data-driven quality assurance. |

| Cost Efficiency | Higher operational costs due to inefficiencies. | Optimized costs through predictive maintenance and analytics. |

| Integration | Isolated systems, limited interoperability. | Seamless integration of CAD, ERP, MES, and supply chain systems. |

Defining the Factory Floor: Traditional Manufacturing Foundations

The factory floor represents the physical environment where traditional manufacturing processes occur, including machinery, assembly lines, and human labor. It serves as the foundational layer for production activities, emphasizing hands-on operations and tangible workflows. Understanding the factory floor's role is essential for integrating emerging technologies like the digital thread, which connects physical processes with digital data streams.

What is the Digital Thread?

The Digital Thread is a seamless flow of data that connects every stage of the manufacturing process from design to production and maintenance, enabling real-time visibility and traceability on the factory floor. By integrating digital information across systems, it enhances decision-making, reduces errors, and accelerates product development cycles. This continuous data exchange transforms traditional manufacturing environments into interconnected smart factories with improved efficiency and quality.

Key Differences Between Factory Floor Operations and Digital Thread

Factory floor operations involve direct management of physical manufacturing processes, including machinery, labor, and raw materials, whereas the digital thread integrates data across the entire product lifecycle for real-time visibility and traceability. The factory floor emphasizes hands-on production control and immediate issue resolution, while the digital thread provides a synchronized flow of digital information enabling predictive analytics and informed decision-making. Key differences center on the tangible execution of manufacturing tasks versus the virtual connectivity and data-driven insights facilitating continuous improvement and innovation.

Integration of Physical and Digital Manufacturing Systems

The integration of factory floor operations with the digital thread enables seamless synchronization between physical manufacturing processes and digital data flow, enhancing real-time monitoring and decision-making. Digital thread technology collects and connects data from machinery, sensors, and production systems on the factory floor, creating a comprehensive digital replica that improves traceability and predictive maintenance. This convergence drives higher efficiency, reduces downtime, and supports adaptive manufacturing workflows through continuous feedback loops between physical assets and digital platforms.

Benefits of Embracing the Digital Thread

Embracing the digital thread in manufacturing integrates data across the entire factory floor, enabling real-time visibility and improved decision-making that boosts operational efficiency and reduces downtime. Digital thread technology connects design, production, and quality control, facilitating seamless traceability and enhanced collaboration among cross-functional teams. This continuous data flow supports predictive maintenance, accelerates innovation, and ultimately drives cost savings and higher product quality.

Challenges in Transitioning from Factory Floor to Digital Thread

Transitioning from the factory floor to a digital thread faces challenges such as data integration complexities, where legacy machinery generates incompatible formats hindering seamless information flow. Workforce adaptation presents difficulties due to skill gaps in digital tools and resistance to change. Ensuring real-time data accuracy and cybersecurity during the digital transformation process remains a critical hurdle for manufacturers.

Impact on Supply Chain Visibility

Factory floor operations generate critical real-time data that enhances supply chain visibility by providing immediate insights into production status and inventory levels. The digital thread integrates this data across the entire product lifecycle, enabling seamless traceability, proactive issue detection, and optimized demand forecasting. Together, these technologies improve supply chain responsiveness, reduce delays, and increase operational efficiency.

Data Flow in Factory Floor vs Digital Thread Environments

Data flow on the factory floor is typically linear and siloed, relying heavily on manual inputs and localized machine data for operational decisions. In contrast, digital thread environments enable continuous, integrated data exchange across the entire product lifecycle, linking design, manufacturing, quality, and supply chain systems in real-time. This seamless connectivity enhances traceability, reduces errors, and accelerates time-to-market through comprehensive data visibility and analytics.

Workforce Implications: Skills for the Future

The factory floor is evolving with digital thread integration, requiring workers to acquire advanced technical skills such as data analytics, IoT device management, and AI-driven process optimization. Embracing digital literacy and continuous learning enables the workforce to bridge traditional manufacturing practices with smart, interconnected systems. Investing in upskilling and reskilling initiatives ensures employees remain competitive and capable of operating within Industry 4.0 environments.

The Future of Manufacturing: Harmonizing Factory Floor and Digital Thread

The future of manufacturing hinges on seamlessly integrating the factory floor with the digital thread to enhance operational efficiency, real-time data transparency, and predictive maintenance. Smart factories leverage Internet of Things (IoT) sensors and digital twins to create interconnected ecosystems that optimize production workflows and reduce downtime. This harmonization drives Industry 4.0 advancements by enabling end-to-end visibility from raw materials to finished products, fostering agile and adaptive manufacturing processes.

Related Important Terms

Cyber-Physical Systems (CPS)

Cyber-Physical Systems (CPS) integrate real-time data from the factory floor with digital thread frameworks to enhance operational efficiency, predictive maintenance, and quality control. This seamless connection between physical manufacturing processes and digital diagnostics enables smarter decision-making and drives Industry 4.0 transformations.

Digital Twin Synchronization

Digital twin synchronization integrates real-time data from the factory floor, enabling continuous alignment between physical operations and virtual models for enhanced manufacturing efficiency. This seamless digital thread ensures accurate simulations, proactive maintenance, and optimized process control throughout the production lifecycle.

Edge-to-Cloud Integration

Factory floor operations leverage real-time data from connected machines, sensors, and control systems, enabling edge computing to process information locally for faster decision-making. Digital thread integration extends this data to the cloud, unifying design, production, and supply chain information to optimize manufacturing efficiency and predictive maintenance.

Real-Time OEE Dashboards

Real-time OEE dashboards on the factory floor integrate data from machinery, production lines, and maintenance systems, enabling immediate visibility into equipment efficiency, downtime, and quality rates. This seamless connection to the digital thread enhances decision-making by providing accurate, up-to-the-minute performance metrics that optimize manufacturing processes and reduce operational bottlenecks.

Data-Driven Workflows

Factory floor operations rely heavily on real-time sensor data and machine feedback to optimize production efficiency, while digital thread technology integrates this data across the product lifecycle for enhanced traceability and decision-making. Data-driven workflows leverage continuous data streams from manufacturing processes to enable predictive maintenance, quality control, and process automation, bridging physical production with digital insights.

IIoT Sensor Fusion

IIoT sensor fusion integrates diverse real-time data from factory floor machinery, enabling enhanced predictive maintenance and operational efficiency through a unified digital thread. This convergence of physical and digital systems improves decision-making accuracy, reduces downtime, and drives smarter manufacturing processes.

Closed-Loop Manufacturing

Closed-loop manufacturing integrates real-time data from the factory floor with digital thread technology to create a seamless feedback system that enhances process control and product quality. This integration enables continuous monitoring, rapid adjustments, and traceability throughout the entire production lifecycle, driving efficiency and reducing defects.

Traceability Chain

Factory floor operations rely heavily on physical records and manual data collection, often leading to fragmented traceability chains and delayed response times. Implementing a digital thread integrates real-time data from IoT devices and sensors across production stages, creating a seamless traceability chain that enhances quality control and reduces downtime.

MES-ERP Convergence

MES-ERP convergence bridges the factory floor and digital thread by enabling real-time data exchange and process synchronization between manufacturing execution systems and enterprise resource planning systems. This integration enhances operational visibility, accelerates decision-making, and optimizes production workflows across the entire value chain.

Shop Floor Digital Shadows

Shop floor digital shadows create real-time, data-driven replicas of factory floor operations, enabling precise monitoring and optimization of manufacturing processes. These digital representations bridge the gap between physical shop floor activities and the digital thread, enhancing traceability, quality control, and predictive maintenance in smart manufacturing environments.

Factory Floor vs Digital Thread Infographic

industrydif.com

industrydif.com