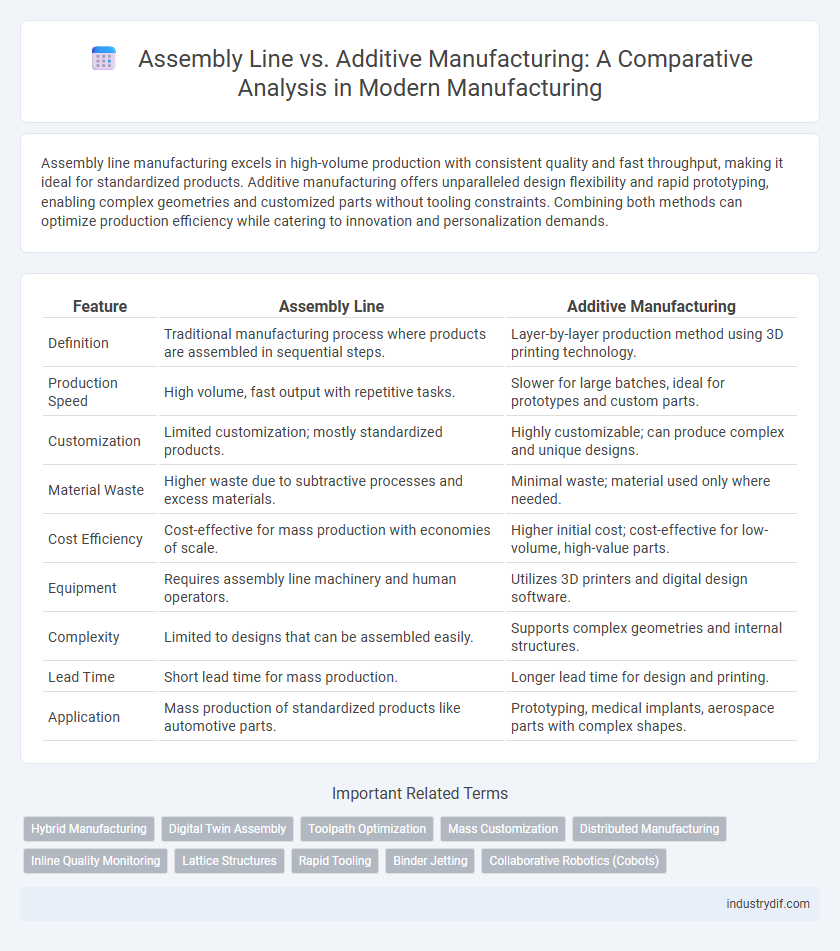

Assembly line manufacturing excels in high-volume production with consistent quality and fast throughput, making it ideal for standardized products. Additive manufacturing offers unparalleled design flexibility and rapid prototyping, enabling complex geometries and customized parts without tooling constraints. Combining both methods can optimize production efficiency while catering to innovation and personalization demands.

Table of Comparison

| Feature | Assembly Line | Additive Manufacturing |

|---|---|---|

| Definition | Traditional manufacturing process where products are assembled in sequential steps. | Layer-by-layer production method using 3D printing technology. |

| Production Speed | High volume, fast output with repetitive tasks. | Slower for large batches, ideal for prototypes and custom parts. |

| Customization | Limited customization; mostly standardized products. | Highly customizable; can produce complex and unique designs. |

| Material Waste | Higher waste due to subtractive processes and excess materials. | Minimal waste; material used only where needed. |

| Cost Efficiency | Cost-effective for mass production with economies of scale. | Higher initial cost; cost-effective for low-volume, high-value parts. |

| Equipment | Requires assembly line machinery and human operators. | Utilizes 3D printers and digital design software. |

| Complexity | Limited to designs that can be assembled easily. | Supports complex geometries and internal structures. |

| Lead Time | Short lead time for mass production. | Longer lead time for design and printing. |

| Application | Mass production of standardized products like automotive parts. | Prototyping, medical implants, aerospace parts with complex shapes. |

Introduction to Modern Manufacturing Techniques

Assembly lines revolutionized manufacturing by enabling mass production through sequential, specialized tasks that boost efficiency and reduce costs. Additive manufacturing, or 3D printing, offers flexibility by building products layer-by-layer from digital designs, allowing rapid prototyping and customization. Combining traditional assembly lines with additive manufacturing enhances production agility and supports complex, low-volume, or bespoke product manufacturing.

Defining Assembly Line Manufacturing

Assembly line manufacturing is a production process where identical products are assembled in a sequential manner across multiple workstations, optimizing efficiency and minimizing labor costs. This method relies heavily on standardized tasks, conveyor systems, and time-motion studies to maximize throughput and maintain consistent quality. Assembly line manufacturing is particularly effective for mass production of automobiles, electronics, and consumer goods.

Understanding Additive Manufacturing

Additive manufacturing builds products layer by layer directly from digital designs, enabling complex geometries unattainable with traditional assembly lines. This process reduces material waste and shortens production cycles by eliminating the need for tooling and molds. Understanding additive manufacturing is essential for harnessing its flexibility, customization potential, and rapid prototyping capabilities in modern manufacturing.

Key Differences Between Assembly Line and Additive Manufacturing

Assembly line manufacturing relies on sequential, repetitive processes with specialized stations optimizing mass production efficiency, whereas additive manufacturing builds products layer-by-layer through 3D printing techniques, allowing for intricate designs and customization. Assembly lines excel in high-volume, uniform product output with lower per-unit costs, while additive manufacturing supports rapid prototyping, complex geometries, and reduced material waste. Key differences include production speed, design flexibility, tooling requirements, and scalability, with assembly lines favoring traditional, large-scale production and additive methods enabling innovation and small-batch manufacturing.

Efficiency and Speed Comparison

Assembly lines excel in high-volume production with consistent speed and streamlined workflows, optimizing efficiency for standardized products through repetitive tasks. Additive manufacturing offers greater flexibility and faster prototyping, reducing lead times for customized or complex parts but often at slower overall production speeds. Efficiency in assembly lines benefits mass production scalability, while additive manufacturing boosts innovation and rapid iteration in low to medium volume runs.

Cost Implications in Production

Assembly line manufacturing typically requires significant upfront investment in machinery and labor but benefits from economies of scale that lower per-unit costs in high-volume production. Additive manufacturing, or 3D printing, reduces tooling expenses and allows for customization, yet generally incurs higher per-unit costs due to slower production speeds and material costs. Cost implications depend on production volume, with assembly lines favored for mass production while additive manufacturing suits low-volume, complex, or prototype-oriented manufacturing.

Material Utilization and Waste Reduction

Assembly lines traditionally optimize material utilization through standardized processes, minimizing waste by streamlining production steps and recycling excess materials. Additive manufacturing significantly enhances material efficiency by building products layer-by-layer, reducing scrap rates and enabling complex geometries without excess raw material consumption. This technology contributes to substantial waste reduction, especially in industries demanding precision and customization, such as aerospace and medical devices.

Flexibility and Customization Capabilities

Assembly lines excel in high-volume, consistent production with limited customization, offering efficiency in standardized manufacturing processes. Additive manufacturing provides superior flexibility and customization, enabling rapid prototyping and tailored products without retooling. This allows manufacturers to adapt quickly to design changes and produce complex geometries not feasible with traditional assembly lines.

Industry-Specific Applications

Assembly lines dominate mass production in automotive and electronics due to high efficiency and consistent output, optimizing repetitive tasks and minimizing cycle time. Additive manufacturing excels in aerospace and medical device industries by enabling complex geometries, rapid prototyping, and customization without the constraints of tooling. Industry-specific applications leverage assembly lines for scale and cost reduction, while additive manufacturing supports innovation and small-batch production in technically demanding sectors.

Future Trends in Assembly Line vs Additive Manufacturing

Future trends in assembly line manufacturing emphasize increased automation, integration of AI-driven robotics, and real-time data analytics to enhance efficiency and reduce downtime. Additive manufacturing continues to advance with innovations in multi-material printing, faster build speeds, and expanded applications in aerospace, healthcare, and automotive industries. The convergence of these technologies is expected to create hybrid production systems that optimize customization while maintaining high throughput and quality control.

Related Important Terms

Hybrid Manufacturing

Hybrid manufacturing combines the high-volume efficiency of traditional assembly lines with the customization and precision of additive manufacturing, enabling rapid production of complex components. Integrating CNC machining with 3D printing technologies enhances flexibility and reduces lead times, optimizing product development in modern manufacturing environments.

Digital Twin Assembly

Digital Twin Assembly integrates real-time data and simulation to optimize both assembly line processes and additive manufacturing workflows, enhancing efficiency and reducing downtime. By creating virtual replicas of physical production systems, manufacturers can predict performance, identify bottlenecks, and implement improvements before actual assembly or printing occurs.

Toolpath Optimization

Toolpath optimization in additive manufacturing enhances precision and reduces material waste by generating efficient deposition paths layer by layer, contrasting the fixed, repetitive nature of assembly line processes that rely on conveyor speed and station timing for efficiency. Advanced software algorithms tailored for additive manufacturing dynamically adjust toolpaths in real-time, improving build quality and cycle times compared to the static tooling and predefined sequences typical in assembly line production.

Mass Customization

Assembly lines excel in high-volume production with limited variability, offering efficiency through standardized processes, while additive manufacturing enables mass customization by producing complex, tailored parts on demand with minimal tooling changes. This flexibility in additive manufacturing supports rapid prototyping and personalized products, reducing lead times and inventory costs compared to traditional assembly line methods.

Distributed Manufacturing

Distributed manufacturing leverages additive manufacturing by enabling decentralized production closer to end-users, reducing logistics costs and lead times compared to traditional assembly lines centralized in single locations. This approach enhances flexibility and customization, allowing manufacturers to rapidly respond to demand fluctuations and local market needs while maintaining efficiency.

Inline Quality Monitoring

Inline quality monitoring in assembly lines leverages real-time sensors and automated inspections to ensure consistent product standards and minimize defects during mass production. Additive manufacturing integrates advanced in-process monitoring techniques such as layer-by-layer thermal imaging and optical scanning to detect anomalies early, improving precision and reducing post-production rework.

Lattice Structures

Lattice structures in additive manufacturing offer superior design flexibility and weight reduction compared to traditional assembly line methods, enabling complex geometries that are difficult to achieve with conventional subtractive processes. These structures optimize material usage and enhance mechanical performance, revolutionizing manufacturing efficiency in aerospace, automotive, and medical industries.

Rapid Tooling

Rapid tooling in assembly line manufacturing accelerates production by creating customized molds and dies that streamline mass production processes. Additive manufacturing offers greater flexibility in rapid tooling by enabling the fast fabrication of complex, low-volume tools directly from digital designs, reducing lead times and costs compared to traditional methods.

Binder Jetting

Binder Jetting in additive manufacturing offers flexibility for producing complex geometries and customized parts without the need for dedicated tooling, contrasting with traditional assembly line methods that rely on repetitive, high-volume production and standardized components. This technology accelerates prototyping and reduces material waste, making it ideal for industries seeking rapid iteration and lightweight structures.

Collaborative Robotics (Cobots)

Collaborative robotics (cobots) enhance assembly lines by improving precision and flexibility, enabling real-time interaction with human workers to optimize production efficiency and reduce errors. In additive manufacturing, cobots facilitate complex, multi-material component construction with adaptable handling and quality inspection, driving innovation and customization at scale.

Assembly Line vs Additive Manufacturing Infographic

industrydif.com

industrydif.com