Industry 4.0 emphasizes automation, data exchange, and smart manufacturing through IoT, AI, and cyber-physical systems, enhancing efficiency and connectivity on the factory floor. Industry 5.0 shifts focus towards human-centric approaches, integrating advanced technologies with human creativity and collaboration to foster personalized production and sustainable practices. The transition from Industry 4.0 to Industry 5.0 marks a move from purely automated processes to synergistic partnerships between humans and machines for smarter, more adaptable manufacturing.

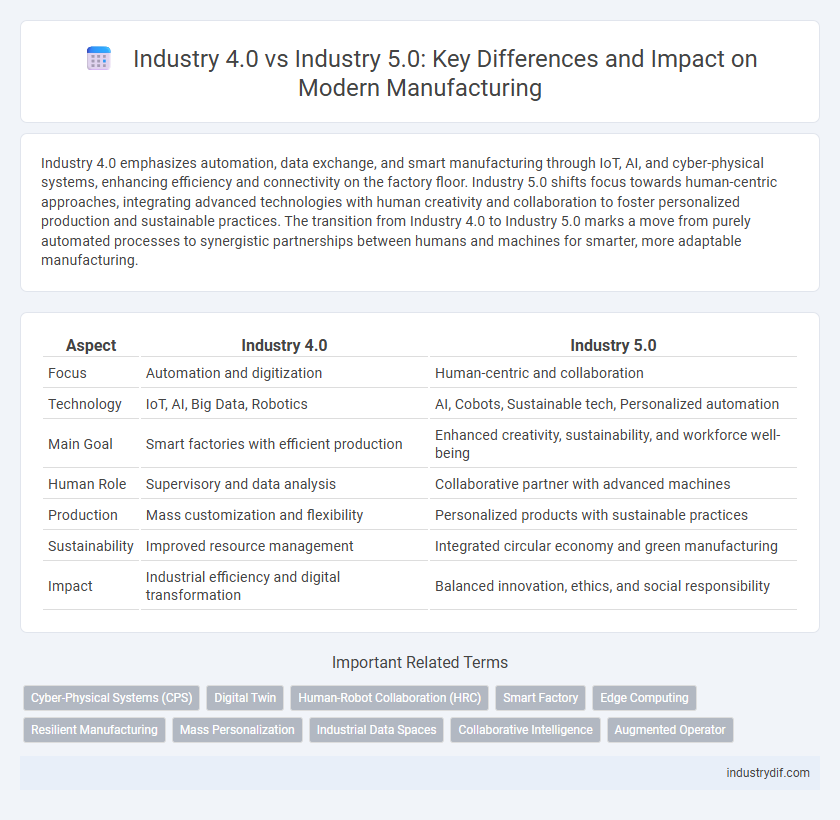

Table of Comparison

| Aspect | Industry 4.0 | Industry 5.0 |

|---|---|---|

| Focus | Automation and digitization | Human-centric and collaboration |

| Technology | IoT, AI, Big Data, Robotics | AI, Cobots, Sustainable tech, Personalized automation |

| Main Goal | Smart factories with efficient production | Enhanced creativity, sustainability, and workforce well-being |

| Human Role | Supervisory and data analysis | Collaborative partner with advanced machines |

| Production | Mass customization and flexibility | Personalized products with sustainable practices |

| Sustainability | Improved resource management | Integrated circular economy and green manufacturing |

| Impact | Industrial efficiency and digital transformation | Balanced innovation, ethics, and social responsibility |

Understanding Industry 4.0: Foundations and Key Technologies

Industry 4.0 revolutionizes manufacturing through the integration of cyber-physical systems, the Internet of Things (IoT), and advanced data analytics, enabling smart factories with real-time monitoring and automation. Core technologies include artificial intelligence, additive manufacturing, cloud computing, and digital twins, which collectively enhance productivity, flexibility, and predictive maintenance. These foundations create a highly interconnected ecosystem, driving efficiency and fostering innovation in production processes.

Unpacking Industry 5.0: Emerging Human-Centric Approaches

Industry 5.0 emphasizes collaboration between humans and advanced technologies such as AI, robotics, and IoT to create more personalized and sustainable manufacturing processes. It builds upon Industry 4.0's automation and data-driven systems by integrating human creativity and skills into production environments. This human-centric approach aims to enhance product customization, improve worker well-being, and foster innovation while maintaining operational efficiency.

Core Differences Between Industry 4.0 and Industry 5.0

Industry 4.0 centers on automation, data exchange, and smart manufacturing systems driven by IoT, AI, and cyber-physical systems to enhance operational efficiency. Industry 5.0 emphasizes human-centric collaboration, integrating advanced robotics with human creativity and expertise to foster sustainable and personalized production. Core differences include Industry 4.0's focus on machine autonomy versus Industry 5.0's emphasis on symbiotic human-machine interaction and ethical, sustainable manufacturing.

Role of Artificial Intelligence in Manufacturing Evolution

Artificial Intelligence in Industry 4.0 primarily optimizes automation, predictive maintenance, and data-driven decision-making, significantly enhancing production efficiency and reducing downtime. Industry 5.0 shifts the focus towards human-machine collaboration, where AI assists skilled workers in customization, quality control, and agile manufacturing processes. This evolution leverages advanced AI algorithms alongside human creativity, driving higher personalization and sustainable manufacturing outcomes.

Human-Robot Collaboration: From Automation to Augmentation

Industry 4.0 emphasizes automation through interconnected systems and smart robotics, streamlining manufacturing processes with minimal human intervention. Industry 5.0 shifts focus toward human-robot collaboration, augmenting human skills with advanced technologies like cobots and AI-driven support systems, enhancing creativity and precision on the factory floor. This transition aims to create a symbiotic relationship between humans and machines, improving productivity while maintaining workforce wellbeing and customization capabilities.

Impact on Workforce: Skills, Jobs, and Training Needs

Industry 4.0 emphasizes automation and digital technologies, shifting workforce skills towards advanced data analysis, robotics, and IT proficiency. Industry 5.0 reintroduces human-centric collaboration, requiring employees to develop skills in creative problem-solving and interpersonal communication alongside technical expertise. Training programs must evolve to include both technological competencies and human-centric skills to prepare workers for hybrid roles in advanced manufacturing environments.

Digital Twins and Smart Factories: Technological Convergence

Industry 4.0 centers on the integration of Digital Twins and Smart Factories, enhancing manufacturing efficiency through real-time data analytics and automation. Industry 5.0 evolves this by combining human creativity with advanced digital technologies, promoting collaborative robots and personalized production. Technological convergence in Industry 5.0 leverages AI-driven Digital Twins to optimize factory operations while integrating human-centric design for sustainable innovation.

Sustainability and Resilience in Modern Manufacturing

Industry 4.0 emphasizes automation, data exchange, and smart manufacturing to enhance efficiency and productivity, leveraging technologies like IoT, AI, and cyber-physical systems. Industry 5.0 shifts the focus towards human-centric collaboration with advanced robotics to achieve sustainability by reducing waste and energy consumption while enhancing manufacturing resilience against supply chain disruptions. Integrating circular economy principles and adaptive manufacturing systems, Industry 5.0 fosters ecological balance and robust production processes in modern manufacturing environments.

Challenges and Barriers to Adopting Industry 5.0

Industry 5.0 introduces human-centric automation and collaborative robots, demanding significant shifts from the fully automated, data-driven systems of Industry 4.0. The primary challenges include integrating advanced robotics with human workforces, addressing cybersecurity risks, and managing high implementation costs. Additionally, skill gaps and resistance to change within organizations create substantial barriers to widespread Industry 5.0 adoption in manufacturing.

Future Trends: Integrating Industry 4.0 and 5.0 Strategies

The future of manufacturing lies in the seamless integration of Industry 4.0's automation, IoT, and data analytics with Industry 5.0's emphasis on human-centric collaboration and sustainability. Emerging trends include advanced AI-driven customization, real-time digital twins, and augmented reality tools that enhance human-machine interaction, boosting productivity and innovation. This convergence enables smart factories to balance efficiency with resilience, addressing evolving market demands and environmental challenges.

Related Important Terms

Cyber-Physical Systems (CPS)

Industry 4.0 leverages Cyber-Physical Systems (CPS) to integrate smart machines and IoT devices, enabling real-time monitoring and automation in manufacturing processes. Industry 5.0 advances CPS by emphasizing human-machine collaboration, enhancing personalized production, and incorporating AI-driven decision-making to boost efficiency and innovation.

Digital Twin

Digital Twin technology in Industry 4.0 enables real-time simulation and predictive maintenance by creating virtual replicas of physical assets, enhancing operational efficiency. Industry 5.0 advances this concept by integrating human creativity and collaboration with AI-driven Digital Twins, fostering personalized production and sustainable manufacturing practices.

Human-Robot Collaboration (HRC)

Industry 4.0 emphasizes automation and cyber-physical systems to increase manufacturing efficiency, while Industry 5.0 prioritizes Human-Robot Collaboration (HRC) by integrating advanced robotics with human creativity and decision-making to enhance customization and resilience. HRC in Industry 5.0 fosters safer, more adaptive production environments through real-time data exchange, collaborative robots (cobots), and artificial intelligence tailored to support human operators.

Smart Factory

Industry 4.0 centers on automation, IoT integration, and data analytics to create interconnected smart factories that optimize production efficiency. Industry 5.0 advances this by emphasizing human-machine collaboration, personalized manufacturing, and sustainable practices, enhancing smart factory adaptability and innovation.

Edge Computing

Industry 4.0 leverages Edge Computing primarily to enhance automation and data processing speed within smart factories, enabling real-time decision-making and predictive maintenance. Industry 5.0 advances this by integrating human-centric collaboration with Edge Computing to optimize personalized production, sustainability, and adaptive manufacturing processes.

Resilient Manufacturing

Industry 5.0 advances beyond Industry 4.0 by integrating human creativity and machine precision to enhance resilient manufacturing, emphasizing adaptability and sustainability in production systems. This evolution leverages collaborative robots and AI-driven analytics to optimize supply chains and minimize downtime, ensuring robust response to disruptions.

Mass Personalization

Industry 4.0 leverages automation, IoT, and AI to enhance efficiency and flexible manufacturing systems, enabling customized production at scale. Industry 5.0 advances this paradigm by integrating human creativity with smart technologies, facilitating mass personalization that combines high-tech precision with individualized customer experiences.

Industrial Data Spaces

Industry 4.0 emphasizes smart factories with interconnected machines and real-time data exchange, whereas Industry 5.0 integrates human-centric approaches alongside advanced technologies, fostering collaboration between humans and machines within Industrial Data Spaces. These data ecosystems enable secure, standardized sharing of manufacturing data across diverse stakeholders, enhancing interoperability, data sovereignty, and innovation in both Industry 4.0 and 5.0 frameworks.

Collaborative Intelligence

Industry 4.0 emphasizes automation and data exchange through IoT, AI, and cyber-physical systems, enhancing smart manufacturing processes. Industry 5.0 advances this by integrating human creativity with collaborative intelligence, fostering personalized production and stronger human-machine collaboration.

Augmented Operator

Industry 4.0 emphasizes automation and data exchange in manufacturing through cyber-physical systems, while Industry 5.0 integrates augmented operators by enhancing human-machine collaboration using advanced AI and augmented reality technologies. This shift aims to combine human creativity and decision-making with machine precision, leading to increased productivity and personalized production processes.

Industry 4.0 vs Industry 5.0 Infographic

industrydif.com

industrydif.com