Factory automation streamlines manufacturing processes using fixed, rule-based systems to perform repetitive tasks efficiently. Hyperautomation extends this concept by integrating advanced technologies like artificial intelligence, machine learning, and robotic process automation to optimize complex workflows and enable adaptive decision-making. This evolution from factory automation to hyperautomation significantly enhances productivity, reduces errors, and fosters scalability in modern manufacturing environments.

Table of Comparison

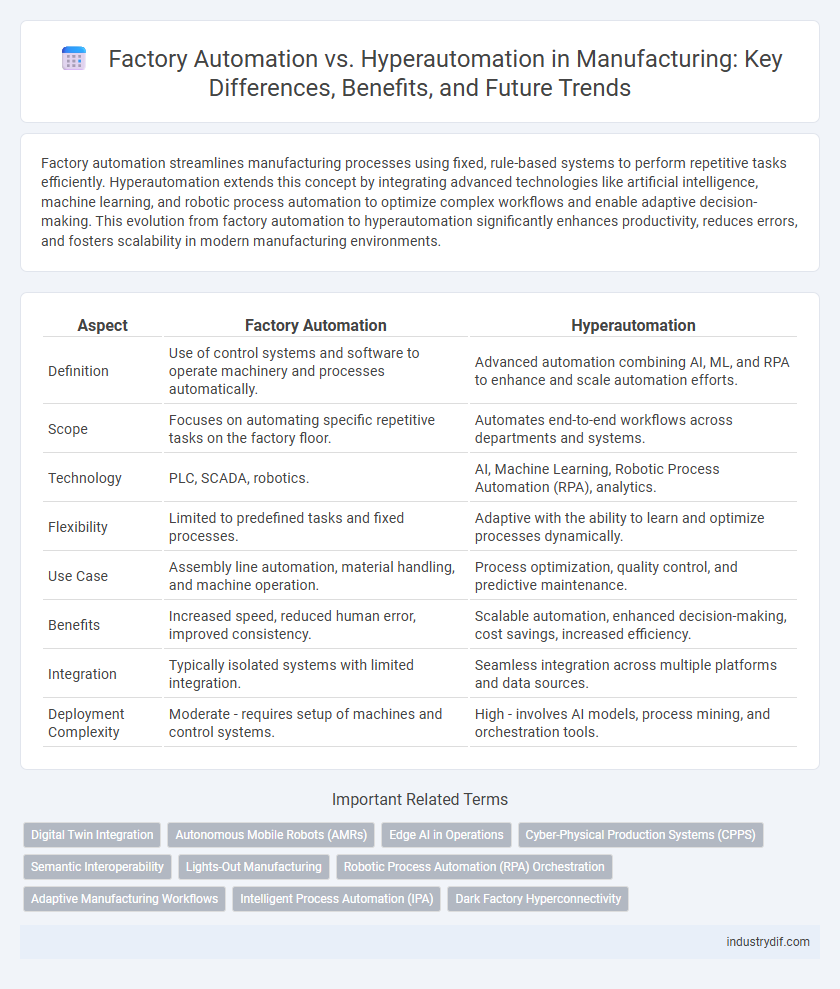

| Aspect | Factory Automation | Hyperautomation |

|---|---|---|

| Definition | Use of control systems and software to operate machinery and processes automatically. | Advanced automation combining AI, ML, and RPA to enhance and scale automation efforts. |

| Scope | Focuses on automating specific repetitive tasks on the factory floor. | Automates end-to-end workflows across departments and systems. |

| Technology | PLC, SCADA, robotics. | AI, Machine Learning, Robotic Process Automation (RPA), analytics. |

| Flexibility | Limited to predefined tasks and fixed processes. | Adaptive with the ability to learn and optimize processes dynamically. |

| Use Case | Assembly line automation, material handling, and machine operation. | Process optimization, quality control, and predictive maintenance. |

| Benefits | Increased speed, reduced human error, improved consistency. | Scalable automation, enhanced decision-making, cost savings, increased efficiency. |

| Integration | Typically isolated systems with limited integration. | Seamless integration across multiple platforms and data sources. |

| Deployment Complexity | Moderate - requires setup of machines and control systems. | High - involves AI models, process mining, and orchestration tools. |

Introduction to Factory Automation and Hyperautomation

Factory automation involves the use of control systems, such as robots and computer software, to operate manufacturing processes with minimal human intervention. Hyperautomation extends this concept by integrating advanced technologies like artificial intelligence, machine learning, and robotic process automation to enhance decision-making and optimize complex workflows. This evolution enables manufacturers to achieve higher efficiency, flexibility, and scalability in production environments.

Key Differences Between Factory Automation and Hyperautomation

Factory automation involves the use of control systems, such as robots and PLCs, to perform repetitive manufacturing tasks with improved efficiency and precision. Hyperautomation extends beyond traditional automation by integrating advanced technologies like artificial intelligence, machine learning, and robotic process automation to optimize entire production workflows and enable real-time decision-making. Key differences include the scope of automation, where factory automation targets individual processes, whereas hyperautomation focuses on end-to-end process orchestration and continuous improvement across complex manufacturing systems.

Core Technologies Driving Factory Automation

Core technologies driving factory automation include robotics, programmable logic controllers (PLCs), and industrial Internet of Things (IIoT) sensors, which streamline production processes and enhance operational efficiency. Hyperautomation integrates artificial intelligence (AI), machine learning (ML), and advanced analytics with traditional automation to enable more intelligent decision-making and adaptive workflows. In manufacturing, these technologies collectively improve precision, reduce downtime, and optimize resource utilization.

The Role of AI and Machine Learning in Hyperautomation

AI and machine learning play a crucial role in hyperautomation by enabling intelligent decision-making and real-time process optimization beyond traditional factory automation. These technologies analyze vast data streams from interconnected systems to identify inefficiencies, predict maintenance needs, and autonomously adjust production workflows. This integration drives higher productivity, reduces downtime, and facilitates adaptive manufacturing environments that continuously evolve through learning algorithms.

Implementation Challenges in Factory Automation

Factory automation faces implementation challenges such as high initial capital expenditure, complex integration with legacy systems, and the need for skilled workforce training. Downtime during installation and system calibration can disrupt production schedules, reducing operational efficiency. Overcoming these obstacles requires careful project planning, modular deployment strategies, and continuous workforce upskilling to ensure seamless automation performance.

Scalability and Flexibility in Hyperautomation

Hyperautomation in manufacturing offers unmatched scalability by integrating advanced AI, machine learning, and robotic process automation to seamlessly expand operations without sacrificing efficiency. Its flexibility allows dynamic adaptation to fluctuating production demands, enabling rapid reconfiguration of workflows and resources. Compared to traditional factory automation, hyperautomation supports continuous process optimization and integration across diverse systems for enhanced operational agility.

Impact on Workforce and Skill Requirements

Factory automation streamlines repetitive tasks through fixed machinery and programmed processes, reducing manual labor and requiring workers to develop skills in equipment maintenance and basic troubleshooting. Hyperautomation integrates advanced technologies like AI, machine learning, and robotic process automation, transforming job roles by demanding higher expertise in digital skills, data analysis, and system management. This shift elevates workforce capabilities, driving continuous learning and increasing the need for adaptable, tech-savvy employees in manufacturing environments.

Cost-Benefit Analysis: Factory Automation vs Hyperautomation

Factory automation reduces labor costs and increases production speed by implementing fixed, repetitive tasks with robotics and control systems, providing a high return on investment for standardized processes. Hyperautomation integrates artificial intelligence, machine learning, and advanced analytics, enabling dynamic decision-making and adaptability, which can lead to greater long-term savings and efficiency improvements despite higher initial costs. A comprehensive cost-benefit analysis must consider upfront investment, scalability, maintenance expenses, and the potential for increased productivity and reduced downtime when comparing factory automation with hyperautomation.

Real-World Use Cases in Manufacturing

Factory automation improves efficiency by utilizing programmable logic controllers (PLCs) and robotics for repetitive tasks, exemplified in automotive assembly lines and packaging systems. Hyperautomation integrates AI, machine learning, and RPA (robotic process automation) to optimize complex workflows such as predictive maintenance and supply chain management, enabling real-time decision-making and adaptive control. Leading manufacturers like Siemens and General Electric demonstrate hyperautomation's impact by reducing downtime and increasing throughput through intelligent data analytics and automated process orchestration.

Future Trends in Industrial Automation

Factory automation integrates programmable logic controllers and robotics to streamline repetitive tasks, enhancing production efficiency and reducing downtime. Hyperautomation leverages artificial intelligence, machine learning, and advanced analytics to autonomously optimize entire manufacturing processes, enabling predictive maintenance and real-time decision-making. Future trends emphasize the convergence of IoT devices with hyperautomation platforms to create fully connected, smart factories that drive agility, scalability, and sustainability in industrial operations.

Related Important Terms

Digital Twin Integration

Factory automation utilizes digital twins primarily to simulate physical equipment and optimize individual processes, while hyperautomation integrates digital twins across entire manufacturing ecosystems to enable real-time data-driven decision-making and predictive analytics. By embedding AI, machine learning, and IoT sensors, hyperautomation extends digital twin applications beyond single machines, creating holistic virtual replicas that drive operational efficiency and agility at scale.

Autonomous Mobile Robots (AMRs)

Autonomous Mobile Robots (AMRs) in factory automation streamline material handling by integrating predefined paths and tasks, enhancing operational efficiency through programmed guidance. Hyperautomation elevates this by combining AMRs with AI-driven decision-making, enabling dynamic task adaptation, real-time process optimization, and end-to-end automated workflows in manufacturing environments.

Edge AI in Operations

Factory automation enhances production efficiency through programmable logic controllers and robotics, while hyperautomation integrates Edge AI to analyze real-time data at the operational level, enabling adaptive decision-making and predictive maintenance. Edge AI in manufacturing reduces latency, improves machine learning accuracy on-site, and supports autonomous process optimization without reliance on cloud connectivity.

Cyber-Physical Production Systems (CPPS)

Cyber-Physical Production Systems (CPPS) integrate physical machinery with digital technologies to enable intelligent factory automation through real-time data processing and adaptive control. Hyperautomation extends CPPS by combining advanced AI, machine learning, and robotic process automation to optimize entire manufacturing workflows, enhancing efficiency and predictive maintenance beyond traditional factory automation capabilities.

Semantic Interoperability

Factory automation streamlines production with predefined workflows and limited data integration, while hyperautomation leverages AI, machine learning, and advanced analytics to enable semantic interoperability across diverse systems and devices. This enhanced semantic interoperability facilitates real-time decision-making, reduces errors, and optimizes complex manufacturing processes through seamless data exchange and context-aware automation.

Lights-Out Manufacturing

Factory automation streamlines repetitive tasks using fixed robotic systems and control software, enhancing efficiency in standardized production lines. Hyperautomation integrates AI, machine learning, and advanced analytics to enable lights-out manufacturing, achieving fully autonomous operations with minimal human intervention and real-time adaptive decision-making.

Robotic Process Automation (RPA) Orchestration

Factory automation streamlines production through programmed machinery and basic robotics, while hyperautomation integrates Robotic Process Automation (RPA) orchestration with AI-driven analytics and process mining to optimize end-to-end workflows. RPA orchestration coordinates diverse automated tasks, enabling seamless data exchange and adaptive decision-making across manufacturing systems for enhanced operational efficiency.

Adaptive Manufacturing Workflows

Factory automation streamlines repetitive tasks using pre-programmed machines, while hyperautomation integrates AI, machine learning, and advanced analytics to create adaptive manufacturing workflows that continuously optimize processes in real-time. Adaptive workflows leverage data-driven insights to dynamically adjust production schedules, resource allocation, and quality control, enhancing operational efficiency and responsiveness in complex manufacturing environments.

Intelligent Process Automation (IPA)

Intelligent Process Automation (IPA) in manufacturing integrates artificial intelligence with automation technologies to optimize complex factory workflows beyond traditional Factory Automation. Hyperautomation leverages IPA to enable end-to-end process digitization and real-time decision-making, significantly enhancing operational efficiency and reducing manual intervention.

Dark Factory Hyperconnectivity

Factory automation enhances production efficiency by using robotics and control systems, while hyperautomation integrates AI-driven processes and real-time data analytics to optimize entire workflows; dark factory hyperconnectivity further elevates this by enabling fully autonomous operations with minimal human intervention through IoT-enabled machine networks and advanced sensor integration. This seamless connectivity in dark factories supports predictive maintenance, real-time decision-making, and adaptive manufacturing environments, significantly reducing downtime and operational costs.

Factory Automation vs Hyperautomation Infographic

industrydif.com

industrydif.com