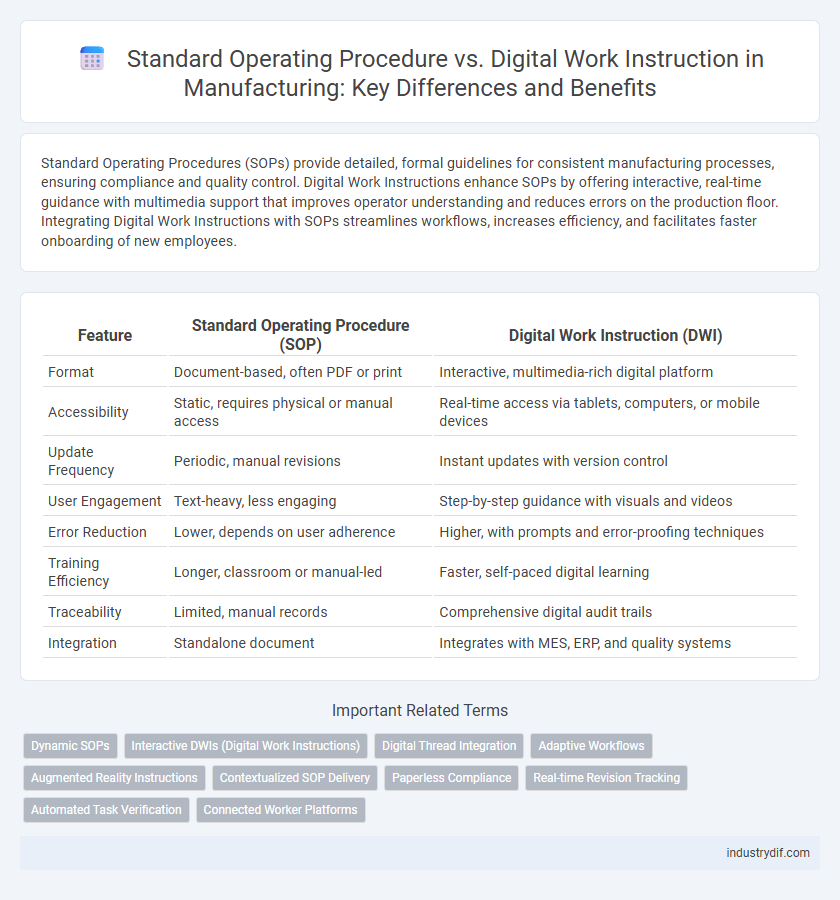

Standard Operating Procedures (SOPs) provide detailed, formal guidelines for consistent manufacturing processes, ensuring compliance and quality control. Digital Work Instructions enhance SOPs by offering interactive, real-time guidance with multimedia support that improves operator understanding and reduces errors on the production floor. Integrating Digital Work Instructions with SOPs streamlines workflows, increases efficiency, and facilitates faster onboarding of new employees.

Table of Comparison

| Feature | Standard Operating Procedure (SOP) | Digital Work Instruction (DWI) |

|---|---|---|

| Format | Document-based, often PDF or print | Interactive, multimedia-rich digital platform |

| Accessibility | Static, requires physical or manual access | Real-time access via tablets, computers, or mobile devices |

| Update Frequency | Periodic, manual revisions | Instant updates with version control |

| User Engagement | Text-heavy, less engaging | Step-by-step guidance with visuals and videos |

| Error Reduction | Lower, depends on user adherence | Higher, with prompts and error-proofing techniques |

| Training Efficiency | Longer, classroom or manual-led | Faster, self-paced digital learning |

| Traceability | Limited, manual records | Comprehensive digital audit trails |

| Integration | Standalone document | Integrates with MES, ERP, and quality systems |

Understanding Standard Operating Procedures in Manufacturing

Standard Operating Procedures (SOPs) in manufacturing define precise, step-by-step instructions to ensure product quality and operational consistency. They serve as critical documents that outline safety guidelines, equipment usage, and quality control measures to minimize errors and downtime. In contrast to digital work instructions, SOPs traditionally rely on static, paper-based formats, which can limit real-time updates and interactive guidance during production processes.

Introduction to Digital Work Instructions

Digital Work Instructions (DWIs) transform traditional Standard Operating Procedures (SOPs) by providing interactive, real-time guidance directly on the manufacturing floor, enhancing accuracy and reducing errors. Unlike static SOPs, DWIs integrate multimedia elements such as videos, images, and step-by-step prompts, which facilitate faster worker training and improved task compliance. This digital approach boosts productivity, supports continuous process improvement, and ensures consistent quality across manufacturing operations.

Key Differences Between SOPs and Digital Work Instructions

Standard Operating Procedures (SOPs) provide detailed, step-by-step instructions ensuring consistent manufacturing processes and compliance with industry regulations. Digital Work Instructions leverage interactive multimedia, real-time updates, and integration with IoT devices to enhance operator guidance and reduce errors. Unlike static SOPs, digital instructions offer dynamic adaptability, improved traceability, and faster revision management in manufacturing environments.

Role of SOPs in Quality Management

Standard Operating Procedures (SOPs) establish consistent quality benchmarks by detailing mandatory processes, ensuring compliance with regulatory standards in manufacturing. Digital Work Instructions enhance the SOP framework by providing real-time, interactive guidance that reduces human error and improves traceability. Together, SOPs and digital work instructions reinforce quality management systems by standardizing workflows and enabling continuous monitoring of production quality metrics.

Advantages of Digital Work Instructions for Modern Manufacturing

Digital work instructions enhance manufacturing efficiency by providing real-time updates, interactive guidance, and multimedia support, reducing errors and training time compared to static Standard Operating Procedures. They enable seamless integration with manufacturing execution systems (MES) and IoT devices, allowing instant data capture and process optimization. This dynamic approach supports continuous improvement, traceability, and compliance, essential for modern Industry 4.0 environments.

Challenges of Traditional SOP Implementation

Traditional Standard Operating Procedures (SOPs) in manufacturing often face challenges such as limited accessibility, reliance on static paper documents, and lack of real-time updates, leading to inconsistent adherence and increased error rates. The inability to integrate SOPs with digital systems hampers effective communication and tracking of compliance, resulting in prolonged training times and operational inefficiencies. These limitations drive the need for Digital Work Instructions that offer interactive, updatable, and easily accessible guidance directly at the point of use.

Enhancing Compliance with Digital Work Instructions

Digital Work Instructions enhance compliance by offering real-time updates and interactive guidance tailored to specific manufacturing tasks, reducing errors compared to static Standard Operating Procedures (SOPs). Integration with manufacturing execution systems (MES) ensures consistent adherence to processes through automated monitoring and feedback. This dynamic approach improves operational accuracy, traceability, and regulatory compliance in manufacturing environments.

Cost Considerations: SOPs vs Digital Work Instructions

Standard Operating Procedures (SOPs) typically incur lower initial costs due to their paper-based format but involve higher ongoing expenses for printing, distribution, and manual updates. Digital Work Instructions require a larger upfront investment in software and hardware but offer significant long-term savings through real-time updates, reduced errors, and enhanced workforce training efficiency. Manufacturing facilities utilizing Digital Work Instructions report an average 20-30% reduction in compliance and training costs compared to traditional SOPs.

Transitioning from SOPs to Digital Work Instructions

Transitioning from Standard Operating Procedures (SOPs) to Digital Work Instructions enhances manufacturing efficiency by providing real-time, interactive guidance accessible on digital devices. Digital Work Instructions improve accuracy and compliance through multimedia elements, such as videos and step-by-step animations, reducing errors compared to traditional paper-based SOPs. Integrating digital instructions into manufacturing execution systems (MES) offers data analytics capabilities, enabling continuous process improvement and faster adaptation to production changes.

Future Trends in Manufacturing Documentation

Standard Operating Procedures (SOPs) are evolving into dynamic Digital Work Instructions (DWIs) that leverage augmented reality (AR) and real-time data integration for enhanced accuracy and efficiency on the manufacturing floor. Future trends emphasize AI-driven customization and IoT connectivity, enabling adaptive instructions that adjust to specific machine states and operator skill levels. This shift boosts operational agility, reduces human error, and accelerates training while ensuring compliance with evolving industry standards.

Related Important Terms

Dynamic SOPs

Dynamic Standard Operating Procedures (SOPs) leverage real-time data integration and interactive digital work instructions to enhance manufacturing precision and adaptability, reducing errors and downtime. Unlike static SOPs, these dynamic SOPs enable continuous updating and contextual customization, aligning with Industry 4.0 practices to optimize workflow efficiency and ensure compliance.

Interactive DWIs (Digital Work Instructions)

Interactive Digital Work Instructions (DWIs) significantly enhance manufacturing efficiency by providing real-time, step-by-step guidance, multimedia integration, and instant feedback, surpassing traditional Standard Operating Procedures (SOPs) limited to static text. These dynamic DWIs reduce errors, accelerate training, and enable seamless process updates, driving higher productivity and consistent quality across production lines.

Digital Thread Integration

Digital Work Instructions enable seamless Digital Thread Integration by linking real-time production data with standardized manufacturing processes, enhancing traceability and quality control. Unlike traditional Standard Operating Procedures, digital formats support dynamic updates and automated feedback loops, driving continuous process optimization and reducing downtime.

Adaptive Workflows

Standard Operating Procedures (SOPs) provide fixed, linear instructions essential for consistent manufacturing processes, while Digital Work Instructions with adaptive workflows enable real-time customization and dynamic task adjustments based on evolving production data. Adaptive workflows enhance operational efficiency by integrating IoT sensors, machine learning algorithms, and user feedback to optimize workflow execution and reduce errors on the manufacturing floor.

Augmented Reality Instructions

Standard Operating Procedures (SOPs) provide detailed, step-by-step guidelines for manufacturing processes, while Digital Work Instructions enhanced with Augmented Reality (AR) overlay interactive, real-time visual cues onto equipment and components, improving accuracy and reducing training time. AR-based instructions increase worker productivity by enabling hands-free access to information, minimizing errors, and accelerating task completion in complex assembly operations.

Contextualized SOP Delivery

Standard Operating Procedures (SOPs) provide detailed, step-by-step instructions essential for maintaining quality and compliance in manufacturing, whereas Digital Work Instructions (DWIs) deliver these guidelines contextually on digital platforms, enhancing real-time accessibility and adaptability on the shop floor. Contextualized SOP delivery through DWIs improves operational efficiency by integrating multimedia elements and responsive workflows tailored to specific tasks, reducing errors and training time in manufacturing processes.

Paperless Compliance

Standard Operating Procedures (SOPs) provide detailed, step-by-step guidelines essential for manufacturing process consistency, while Digital Work Instructions enable real-time, interactive task guidance that enhances paperless compliance through automated tracking and audit trails. Leveraging digital platforms reduces errors, accelerates updates, and ensures adherence to regulatory standards by maintaining accurate, accessible records without physical paperwork.

Real-time Revision Tracking

Standard Operating Procedures (SOPs) provide structured guidelines but often lack efficient real-time revision tracking, causing delays in updating critical manufacturing processes. Digital Work Instructions leverage cloud-based platforms and version control systems to enable immediate updates and transparent change logs, ensuring operators always access the most current and compliant procedures on the production line.

Automated Task Verification

Standard Operating Procedures (SOPs) provide detailed, step-by-step instructions to ensure consistent manufacturing processes, while Digital Work Instructions (DWIs) enhance automation by integrating real-time task verification through sensors and data analytics. Automated task verification in DWIs reduces human error and increases compliance by validating each step during production, leading to improved efficiency and quality control.

Connected Worker Platforms

Standard Operating Procedures (SOPs) provide foundational process guidelines, while Digital Work Instructions (DWIs) delivered via Connected Worker Platforms enhance real-time task execution through interactive, context-specific updates and multimedia integration. Leveraging IoT sensors and augmented reality, these platforms increase operational efficiency, reduce errors, and enable continuous feedback loops for manufacturing workforce optimization.

Standard Operating Procedure vs Digital Work Instruction Infographic

industrydif.com

industrydif.com