Factory workers in traditional manufacturing primarily perform manual tasks with limited automation, whereas Industry 5.0 emphasizes seamless human-machine collaboration to enhance productivity and innovation. Advanced technologies such as cobots, AI-driven systems, and IoT enable workers to focus on complex problem-solving and creative decision-making. This integration improves safety, efficiency, and job satisfaction by leveraging the unique strengths of both humans and machines.

Table of Comparison

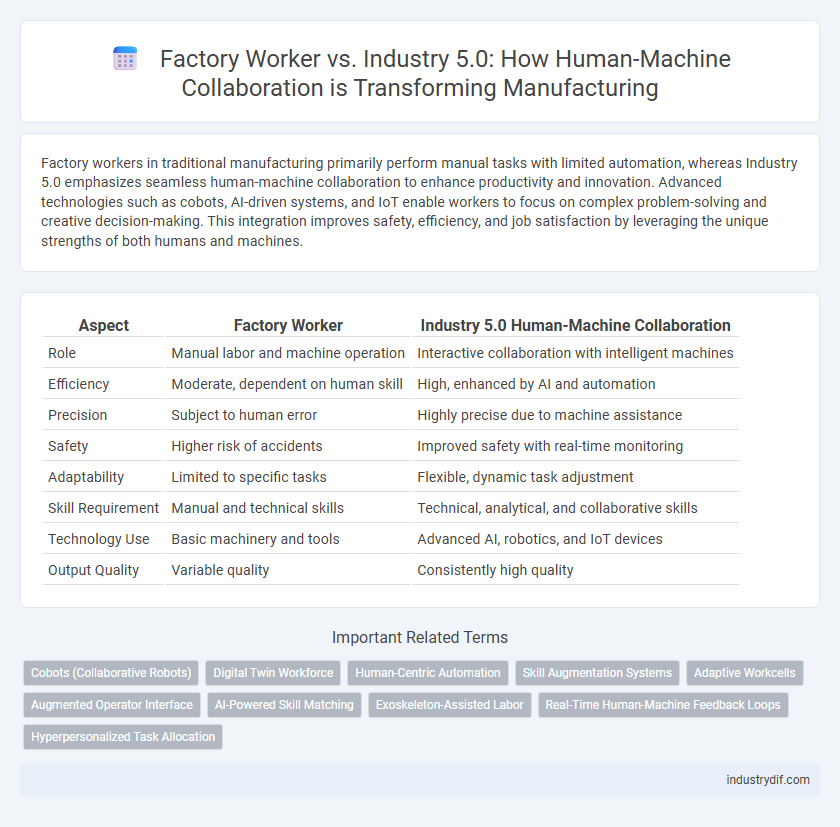

| Aspect | Factory Worker | Industry 5.0 Human-Machine Collaboration |

|---|---|---|

| Role | Manual labor and machine operation | Interactive collaboration with intelligent machines |

| Efficiency | Moderate, dependent on human skill | High, enhanced by AI and automation |

| Precision | Subject to human error | Highly precise due to machine assistance |

| Safety | Higher risk of accidents | Improved safety with real-time monitoring |

| Adaptability | Limited to specific tasks | Flexible, dynamic task adjustment |

| Skill Requirement | Manual and technical skills | Technical, analytical, and collaborative skills |

| Technology Use | Basic machinery and tools | Advanced AI, robotics, and IoT devices |

| Output Quality | Variable quality | Consistently high quality |

Introduction to Factory Workers in Modern Manufacturing

Factory workers in modern manufacturing play a crucial role in Industry 5.0 by seamlessly integrating human skills with advanced machinery to enhance productivity and precision. Collaborative robots (cobots) assist workers by performing repetitive tasks, allowing humans to focus on complex problem-solving and quality control. This symbiotic relationship boosts efficiency, reduces errors, and fosters innovation on the factory floor.

Understanding Industry 5.0: A New Era of Collaboration

Industry 5.0 redefines factory worker roles by emphasizing seamless human-machine collaboration, enhancing precision and efficiency through advanced robotics and AI integration. Workers interact with smart machines that augment cognitive skills, enabling real-time decision-making and customization in manufacturing processes. This synergy drives sustainable production and innovation, marking a shift from traditional automation to a more collaborative industrial environment.

Key Differences between Traditional Factory Workers and Industry 5.0 Operators

Traditional factory workers primarily perform manual and repetitive tasks with limited interaction with machines, relying heavily on physical labor and routine processes. Industry 5.0 operators engage in advanced human-machine collaboration, utilizing artificial intelligence, robotics, and real-time data analytics to enhance precision, efficiency, and customization in manufacturing. The key differences lie in the integration of intelligent systems, the shift from manual labor to supervisory roles, and the emphasis on personalized and sustainable production methods.

Evolving Roles: Human-Machine Synergy in Manufacturing

Factory workers in Industry 5.0 transition from manual operators to collaborators with intelligent machines, enhancing productivity through real-time data integration and adaptive automation. Human-machine synergy enables personalized manufacturing processes, where workers leverage cognitive systems for decision-making and quality control. This evolution fosters a flexible workforce capable of managing complex tasks alongside AI-driven robots, promoting innovation and sustainable industrial growth.

Essential Skills for Industry 5.0 Workforce

Industry 5.0 emphasizes human-machine collaboration, requiring factory workers to develop advanced digital literacy, problem-solving abilities, and emotional intelligence to effectively interact with smart machines. Essential skills include proficiency in robotics operation, data analysis, and adaptive learning to optimize production processes while maintaining human creativity and decision-making. Continuous upskilling in AI integration and cybersecurity safeguards industrial workflows and enhances worker-machine synergy in modern manufacturing environments.

Benefits of Human-Centric Automation in Factories

Human-centric automation in Industry 5.0 enhances factory worker productivity by integrating advanced robotics with human skills, resulting in increased precision and reduced fatigue. Collaborative robots (cobots) support complex tasks, enabling personalized customization and real-time adjustments, which improve product quality. This synergy boosts worker safety, job satisfaction, and innovation, transforming traditional manufacturing into adaptive, efficient smart factories.

Technology Integration: Cobots and Smart Tools

Factory workers increasingly rely on collaborative robots (cobots) and smart tools that enhance precision and efficiency in Industry 5.0 environments, enabling seamless human-machine collaboration. Advanced sensors and AI-driven interfaces facilitate real-time communication between workers and machinery, reducing errors and improving productivity. This integration transforms traditional roles by augmenting human capabilities with adaptive automation technologies tailored to dynamic manufacturing processes.

Workplace Safety and Wellbeing in Human-Machine Teams

Factory workers in Industry 5.0 environments benefit from advanced human-machine collaboration that significantly enhances workplace safety through real-time monitoring and adaptive automation. Ergonomic robotic systems and AI-powered safety protocols reduce physical strain and minimize accidents, promoting worker wellbeing. Integrating wearable sensors and collaborative robots enables seamless communication between humans and machines, fostering a safer and more productive manufacturing ecosystem.

Challenges in Transitioning to Industry 5.0

Transitioning from traditional factory worker roles to Industry 5.0 human-machine collaboration presents significant challenges, including the need for advanced technical skills and continuous upskilling to operate sophisticated AI-driven machinery. Integrating collaborative robots (cobots) requires redesigning workflows and addressing worker safety concerns in increasingly automated environments. Resistance to change and managing the balance between human creativity and machine precision also complicate the shift toward Industry 5.0 manufacturing ecosystems.

The Future Outlook: Empowering Workers through Advanced Collaboration

Industry 5.0 transforms factory workers' roles by integrating advanced human-machine collaboration, enhancing productivity and job satisfaction. Smart machines equipped with AI and robotics work alongside employees, providing real-time assistance, reducing manual labor, and enabling creative problem-solving. This synergy empowers workers, fostering a resilient, adaptive workforce that drives innovation and sustainable manufacturing growth.

Related Important Terms

Cobots (Collaborative Robots)

Factory workers equipped with cobots in Industry 5.0 environments experience enhanced productivity and safety by leveraging collaborative robots designed for intuitive human-machine interaction. These cobots optimize precision in repetitive tasks, reduce physical strain, and enable real-time adaptability, bridging the gap between human skills and advanced robotics in modern manufacturing.

Digital Twin Workforce

Factory workers increasingly leverage Digital Twin Workforce technology to enhance real-time monitoring, predictive maintenance, and workflow optimization within Industry 5.0 environments. This human-machine collaboration reduces operational downtime and improves decision-making accuracy by simulating physical processes through digital replicas.

Human-Centric Automation

Factory workers increasingly engage with Industry 5.0 human-machine collaboration, where human-centric automation enhances productivity by integrating operator skills with advanced robotics. This synergy prioritizes ergonomic design and real-time feedback, fostering safer environments and tailored workflows that amplify worker expertise while reducing physical strain.

Skill Augmentation Systems

Factory workers equipped with skill augmentation systems in Industry 5.0 experience enhanced productivity through real-time data integration, wearable sensors, and AI-driven decision support tools. These technologies enable seamless human-machine collaboration, improving precision, reducing errors, and fostering adaptive learning on the manufacturing floor.

Adaptive Workcells

Adaptive Workcells in Industry 5.0 enhance factory worker efficiency by integrating human-machine collaboration, enabling real-time adjustments and personalized automation. This approach reduces downtime and increases precision compared to traditional factory setups, promoting a dynamic, responsive manufacturing environment.

Augmented Operator Interface

Factory workers equipped with Augmented Operator Interfaces in Industry 5.0 experience enhanced human-machine collaboration through real-time data visualization and intuitive controls, significantly improving operational efficiency and decision-making accuracy. This advanced interface integrates AI-powered analytics and wearable technology to optimize task execution while maintaining worker safety and reducing cognitive load.

AI-Powered Skill Matching

AI-powered skill matching in Industry 5.0 enhances factory worker efficiency by dynamically pairing human expertise with machine capabilities, enabling personalized task allocation that maximizes productivity and reduces downtime. This advanced collaboration leverages real-time data and adaptive learning algorithms to continuously optimize workforce deployment, fostering a symbiotic relationship between humans and intelligent systems in manufacturing environments.

Exoskeleton-Assisted Labor

Exoskeleton-assisted labor in Industry 5.0 enhances factory worker productivity by combining human dexterity with mechanical strength, reducing physical strain and injury risk. This human-machine collaboration optimizes workflow efficiency and promotes sustainable manufacturing practices through advanced wearable robotics.

Real-Time Human-Machine Feedback Loops

Factory workers in Industry 5.0 environments benefit from real-time human-machine feedback loops that enhance precision and reduce errors by enabling instantaneous adjustments during production processes. This continuous data exchange revolutionizes traditional manufacturing by fostering dynamic collaboration between humans and machines, leading to improved productivity and adaptive decision-making.

Hyperpersonalized Task Allocation

Hyperpersonalized task allocation in Industry 5.0 leverages advanced AI and real-time data analytics to match factory workers' unique skills and preferences with specific manufacturing tasks, significantly enhancing efficiency and job satisfaction. This approach contrasts with traditional factory workflows by fostering seamless human-machine collaboration, where intelligent systems dynamically adapt workloads to optimize productivity and reduce human error.

Factory Worker vs Industry 5.0 Human-Machine Collaboration Infographic

industrydif.com

industrydif.com