Assembly lines maximize efficiency by streamlining repetitive tasks and enabling mass production, reducing per-unit costs through economies of scale. Microfactories offer flexibility and rapid customization with compact layouts that allow for quick adaptation to product changes and smaller batch sizes. Choosing between assembly lines and microfactories depends on production volume, product complexity, and the need for agility in manufacturing processes.

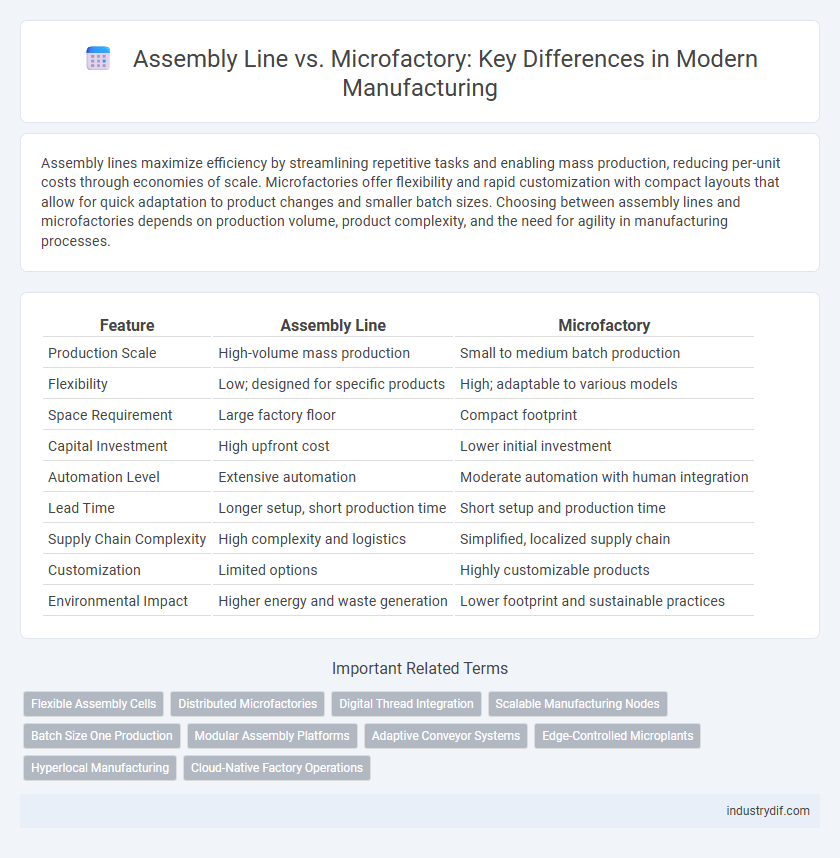

Table of Comparison

| Feature | Assembly Line | Microfactory |

|---|---|---|

| Production Scale | High-volume mass production | Small to medium batch production |

| Flexibility | Low; designed for specific products | High; adaptable to various models |

| Space Requirement | Large factory floor | Compact footprint |

| Capital Investment | High upfront cost | Lower initial investment |

| Automation Level | Extensive automation | Moderate automation with human integration |

| Lead Time | Longer setup, short production time | Short setup and production time |

| Supply Chain Complexity | High complexity and logistics | Simplified, localized supply chain |

| Customization | Limited options | Highly customizable products |

| Environmental Impact | Higher energy and waste generation | Lower footprint and sustainable practices |

Introduction to Assembly Lines and Microfactories

Assembly lines streamline mass production by dividing tasks into sequential steps, boosting efficiency and consistency in manufacturing processes. Microfactories utilize compact, flexible setups designed for small-scale, customized production, enabling rapid prototyping and localized manufacturing. Choosing between assembly lines and microfactories depends on production volume, customization needs, and scalability requirements.

Historical Evolution of Manufacturing Systems

Assembly lines revolutionized manufacturing in the early 20th century by introducing sequential, mechanized production, dramatically increasing output and efficiency in mass production industries. Microfactories emerged in the 21st century, leveraging advanced automation and digital technologies to enable flexible, small-scale manufacturing closer to end users. This evolution reflects a shift from centralized, large-scale assembly lines to decentralized, responsive microfactories tailored for customization and rapid market adaptation.

Core Principles of Assembly Line Production

Assembly line production centers on the principle of sequential task specialization where each worker or machine performs a specific operation repetitively, enhancing efficiency and reducing production time. The standardized workflow and division of labor in assembly lines enable mass production and consistent quality control. Emphasis on minimizing downtime and streamlining component transfer between stations forms the core operational strategy of assembly line systems.

Defining Microfactory Concepts

Microfactories represent a decentralized manufacturing model characterized by compact, modular production units that enable localized assembly and rapid customization. Unlike traditional assembly lines, microfactories emphasize flexibility, lean workflows, and integration of advanced automation and digital technologies for efficient small-batch production. This approach reduces supply chain complexity, lowers capital investment, and accelerates product-to-market timelines by leveraging scalable, adaptable manufacturing ecosystems.

Key Differences: Assembly Line vs Microfactory

Assembly lines are large-scale manufacturing systems designed for mass production with sequential workstations optimizing efficiency and throughput. Microfactories operate on a smaller scale, emphasizing flexibility, customization, and local production by integrating automated technologies in compact spaces. Key differences include the scale of operation, production volume, customization ability, and facility footprint, with assembly lines suited for standardized products and microfactories ideal for agile manufacturing.

Flexibility and Scalability in Production

Assembly lines offer high scalability through standardized processes but often lack flexibility when adapting to product variations or small batch production. Microfactories provide enhanced flexibility by enabling rapid product changes and customization, supporting diverse product lines with minimal retooling. This adaptability allows microfactories to scale production efficiently in response to fluctuating market demands, outperforming traditional assembly lines in dynamic manufacturing environments.

Technology and Automation in Both Systems

Assembly lines rely on conveyor systems and robotic arms for high-volume, standardized production, optimizing speed and efficiency through repetitive tasks. Microfactories integrate advanced automation technologies such as AI-driven robotics and IoT sensors to enable flexible, small-batch manufacturing with real-time data analytics. Both systems leverage automation, but microfactories emphasize adaptability and smart technology for customized production, whereas assembly lines focus on maximizing throughput with consistent, linear workflows.

Cost Efficiency: Initial Investment and Operational Expenses

Assembly lines require a significant initial capital investment due to extensive infrastructure and specialized machinery, resulting in higher fixed costs but lower operational expenses per unit through economies of scale. Microfactories demand lower upfront investment with modular, flexible equipment enabling quick setup and adaptability, though operational costs per unit may be higher due to smaller production volumes. Evaluating cost efficiency involves balancing the substantial initial outlay and lower variable costs of assembly lines against the scalable, lower upfront expenses and potentially increased operational costs of microfactories.

Environmental Impact and Sustainability

Assembly lines typically consume more energy and generate higher waste due to large-scale production and extensive resource use, impacting environmental sustainability negatively. Microfactories emphasize localized production with minimal waste, energy efficiency, and reduced carbon footprints, promoting sustainable manufacturing practices. By integrating renewable energy and circular economy principles, microfactories support greener supply chains and decrease overall environmental impact compared to traditional assembly lines.

Future Trends in Manufacturing: Assembly Line and Microfactory Integration

Integrating assembly line systems with microfactory models is poised to revolutionize manufacturing by enhancing scalability, flexibility, and efficiency. Advanced automation, IoT connectivity, and AI-driven analytics enable real-time adjustments and predictive maintenance across both setups, reducing downtime and optimizing production flow. This hybrid approach supports localized, customized manufacturing while maintaining high throughput, aligning with Industry 4.0 trends and sustainable manufacturing goals.

Related Important Terms

Flexible Assembly Cells

Flexible assembly cells in microfactories enhance manufacturing agility by allowing rapid reconfiguration for diverse product types, unlike traditional assembly lines designed for high-volume, uniform output. These cells leverage modular equipment and automation technologies to optimize space and reduce changeover times, driving cost efficiency and customization capabilities.

Distributed Microfactories

Distributed microfactories optimize manufacturing by decentralizing production into smaller, flexible units that reduce lead times and increase customization capabilities compared to traditional assembly lines. These microfactories leverage advanced automation and real-time data analytics to enhance efficiency, scalability, and responsiveness across geographically dispersed locations.

Digital Thread Integration

Assembly lines benefit from digital thread integration by enabling real-time data flow across production stages, enhancing process traceability and reducing downtime through predictive maintenance. Microfactories leverage digital threads to facilitate flexible, localized manufacturing with seamless design-to-production data continuity, accelerating product customization and faster time-to-market.

Scalable Manufacturing Nodes

Assembly lines enable high-volume production through linear, sequential processes ideal for standardized products, while microfactories leverage scalable manufacturing nodes to offer flexible, localized, and modular production capacity. Microfactories support rapid adaptability and decentralized manufacturing, reducing transportation costs and lead times compared to traditional assembly line systems.

Batch Size One Production

Assembly lines excel in high-volume production but lack flexibility for Batch Size One manufacturing, where customization and rapid changeover are crucial. Microfactories optimize Batch Size One by utilizing compact, modular equipment and advanced automation to deliver personalized products efficiently at low volumes.

Modular Assembly Platforms

Modular assembly platforms revolutionize manufacturing by enabling flexible, scalable assembly lines that reduce setup time and increase productivity compared to traditional linear assembly lines. Microfactories leverage these platforms to optimize space and integrate advanced automation, enhancing customization and minimizing production costs.

Adaptive Conveyor Systems

Adaptive conveyor systems in assembly lines enable real-time adjustments to speed and routing, enhancing efficiency and reducing downtime in mass production environments. Microfactories leverage these systems for flexible, small-scale manufacturing, allowing rapid changeovers and customization to meet diverse market demands.

Edge-Controlled Microplants

Edge-controlled microplants revolutionize manufacturing by integrating assembly line efficiency with localized, real-time data processing to enhance production flexibility and reduce latency. These microfactories enable decentralized control and rapid customization, outperforming traditional assembly lines in responsiveness and scalability.

Hyperlocal Manufacturing

Assembly lines excel in high-volume production with standardized processes, whereas microfactories emphasize hyperlocal manufacturing by enabling flexible, small-scale production closer to end consumers. Hyperlocal manufacturing reduces supply chain disruptions and carbon emissions, leveraging automation and digital tools to customize products swiftly within microfactories.

Cloud-Native Factory Operations

Assembly lines streamline mass production through standardized workflows and fixed stations, while microfactories leverage cloud-native factory operations to enable agile, scalable, and data-driven manufacturing processes. Cloud-native platforms integrate IoT, AI, and real-time analytics, enhancing flexibility, reducing downtime, and optimizing resource allocation in microfactories compared to traditional assembly line systems.

Assembly Line vs Microfactory Infographic

industrydif.com

industrydif.com