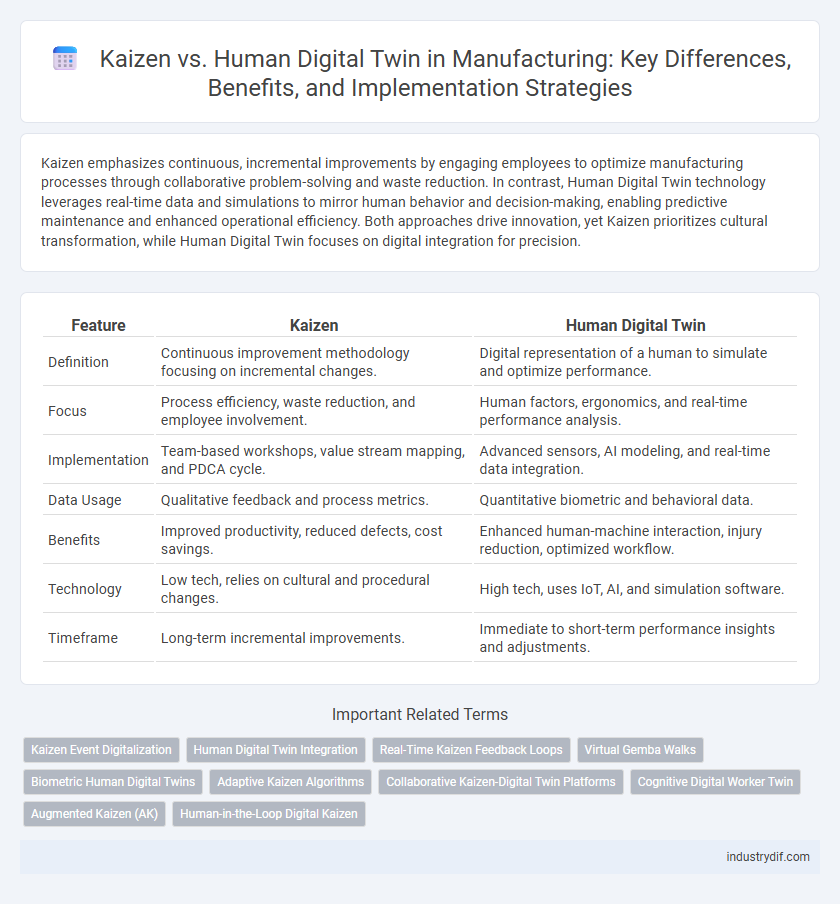

Kaizen emphasizes continuous, incremental improvements by engaging employees to optimize manufacturing processes through collaborative problem-solving and waste reduction. In contrast, Human Digital Twin technology leverages real-time data and simulations to mirror human behavior and decision-making, enabling predictive maintenance and enhanced operational efficiency. Both approaches drive innovation, yet Kaizen prioritizes cultural transformation, while Human Digital Twin focuses on digital integration for precision.

Table of Comparison

| Feature | Kaizen | Human Digital Twin |

|---|---|---|

| Definition | Continuous improvement methodology focusing on incremental changes. | Digital representation of a human to simulate and optimize performance. |

| Focus | Process efficiency, waste reduction, and employee involvement. | Human factors, ergonomics, and real-time performance analysis. |

| Implementation | Team-based workshops, value stream mapping, and PDCA cycle. | Advanced sensors, AI modeling, and real-time data integration. |

| Data Usage | Qualitative feedback and process metrics. | Quantitative biometric and behavioral data. |

| Benefits | Improved productivity, reduced defects, cost savings. | Enhanced human-machine interaction, injury reduction, optimized workflow. |

| Technology | Low tech, relies on cultural and procedural changes. | High tech, uses IoT, AI, and simulation software. |

| Timeframe | Long-term incremental improvements. | Immediate to short-term performance insights and adjustments. |

Introduction to Kaizen and Human Digital Twin

Kaizen is a continuous improvement methodology emphasizing incremental changes to enhance manufacturing efficiency and quality through employee involvement and standardized processes. Human Digital Twin technology creates a virtual replica of workers, enabling real-time monitoring and optimization of human performance and safety in production environments. Combining Kaizen principles with Human Digital Twin data accelerates process innovation and supports data-driven decision-making in manufacturing operations.

Core Principles of Kaizen in Manufacturing

Kaizen in manufacturing centers on continuous small improvements driven by employee involvement and standardized processes to enhance efficiency and reduce waste. It emphasizes the elimination of non-value-added activities through collaborative problem-solving and incremental changes. This approach fosters a culture of sustained quality improvement, contrasting with the predictive and simulation capabilities of Human Digital Twin technology.

Understanding Human Digital Twin Technology

Human Digital Twin technology in manufacturing creates a real-time digital replica of a worker's physiological and cognitive states, enabling precise monitoring and predictive analysis of human performance. Unlike Kaizen, which emphasizes continuous incremental improvements through human intervention and feedback, Human Digital Twin leverages AI and IoT sensors to simulate and optimize individual behaviors and workflows automatically. This technology enhances decision-making accuracy and operational efficiency by providing data-driven insights into human-machine interactions and personalized productivity enhancements.

Key Differences: Kaizen vs Human Digital Twin

Kaizen emphasizes continuous incremental improvements through employee-driven processes and cultural change, fostering operational efficiency in manufacturing. Human Digital Twin leverages real-time data and advanced simulations of individual workers to optimize performance, health, and safety on the shop floor. The key difference lies in Kaizen's focus on human-centric, gradual process enhancements versus Human Digital Twin's technology-driven, personalized performance analytics.

Impact on Operational Efficiency

Kaizen drives continuous incremental improvements by empowering employees to identify inefficiencies and implement small-scale process enhancements, resulting in steady gains in operational efficiency. Human Digital Twin technology leverages real-time data and advanced simulations to optimize workflows and predict maintenance needs, significantly reducing downtime and increasing productivity. Integrating Kaizen with Human Digital Twin enables manufacturers to combine employee-driven insights with data-driven precision, maximizing operational efficiency and fostering agile manufacturing processes.

Integration with Industry 4.0 Solutions

Kaizen emphasizes continuous incremental improvements driven by human insights, enhancing efficiency through collaborative problem-solving and real-time feedback loops. Human Digital Twin technology integrates with Industry 4.0 by creating dynamic virtual replicas of workers, enabling simulation, monitoring, and optimization of human-machine interactions to boost productivity and safety. Combining Kaizen methodologies with Human Digital Twins supports data-driven decision-making and adaptive process refinement in smart manufacturing environments.

Employee Involvement: Human Factors in Both Approaches

Kaizen emphasizes continuous employee involvement through incremental improvements, fostering a culture of collaboration and hands-on problem-solving to optimize manufacturing processes. In contrast, Human Digital Twins use advanced simulation and data analytics to model employee behavior and ergonomics, enabling personalized feedback and training without direct physical intervention. Both approaches prioritize human factors, yet Kaizen relies on active human participation while Human Digital Twins leverage digital representation for enhanced decision-making.

Data Collection and Continuous Improvement

Kaizen relies on manual data collection and incremental improvements driven by employee feedback and repetitive processes, fostering gradual operational enhancements. Human Digital Twin technology enables real-time data acquisition through sensors and advanced analytics, creating a dynamic virtual replica of workers to optimize performance and ergonomic factors continually. The integration of Human Digital Twins accelerates continuous improvement by providing precise, data-driven insights that complement Kaizen's culture of ongoing, collaborative refinement.

Real-world Applications in Modern Factories

Kaizen drives continuous improvement in manufacturing through incremental changes by empowering employees to identify inefficiencies and optimize processes over time. Human Digital Twin technology leverages real-time data and AI to create virtual replicas of workers, enabling predictive analysis and personalized training to enhance safety and productivity. Modern factories implement Kaizen for cultural transformation while integrating Human Digital Twins to accelerate decision-making and minimize downtime through precise simulations.

Future Trends: Synergies and Challenges

Kaizen in manufacturing emphasizes continuous incremental improvements driven by human insights, while Human Digital Twins leverage advanced digital simulations to optimize processes and worker performance. Emerging trends highlight synergies where Kaizen methodologies integrate with Human Digital Twin data analytics to accelerate decision-making and predictive maintenance. Challenges include ensuring data accuracy, protecting worker privacy, and aligning human-centric cultures with digital transformation initiatives.

Related Important Terms

Kaizen Event Digitalization

Kaizen event digitalization integrates real-time data analytics and digital collaboration tools to enhance continuous improvement processes, reducing cycle times and increasing operational efficiency in manufacturing. Unlike traditional human digital twins that simulate individual worker behavior, Kaizen digitalization focuses on collective workflow optimization and rapid problem-solving through virtual event platforms.

Human Digital Twin Integration

Human Digital Twin integration in manufacturing enables real-time data synchronization between physical workers and their virtual counterparts, enhancing process optimization and predictive maintenance. Unlike Kaizen's continuous improvement approach, Human Digital Twins leverage AI-driven simulations to personalize training, monitor performance, and reduce downtime through proactive intervention.

Real-Time Kaizen Feedback Loops

Real-time Kaizen feedback loops enable continuous process improvements by capturing live data on manufacturing performance, while Human Digital Twin technology simulates operator behavior to optimize workflows and ergonomics. Integrating these systems accelerates decision-making with precise, actionable insights, enhancing operational efficiency and reducing downtime.

Virtual Gemba Walks

Kaizen emphasizes continuous, incremental improvements through direct observation and employee involvement, while Human Digital Twin technology enables Virtual Gemba Walks by creating real-time, data-driven simulations of factory operations to identify inefficiencies remotely. Integrating Human Digital Twins in manufacturing enhances decision-making precision, reduces downtime, and accelerates process optimization compared to traditional Kaizen methods.

Biometric Human Digital Twins

Kaizen emphasizes continuous incremental improvements in manufacturing processes, while biometric Human Digital Twins leverage real-time physiological data to optimize worker performance and safety. Integrating biometric Human Digital Twins with Kaizen strategies enhances precision in identifying inefficiencies and personalizing ergonomic interventions on the factory floor.

Adaptive Kaizen Algorithms

Adaptive Kaizen algorithms enhance manufacturing efficiency by integrating real-time data from Human Digital Twins to continuously optimize processes and reduce waste. Leveraging digital representations of workers, these algorithms dynamically adjust workflows to improve productivity, quality, and employee well-being in smart factories.

Collaborative Kaizen-Digital Twin Platforms

Collaborative Kaizen-Digital Twin platforms integrate continuous improvement methodologies with advanced digital twin simulations, enhancing real-time decision-making and process optimization in manufacturing. These platforms enable seamless interaction between human expertise and digital models, driving operational efficiency, predictive maintenance, and adaptive workflow enhancements.

Cognitive Digital Worker Twin

Kaizen emphasizes continuous incremental improvements driven by human insight, while Cognitive Digital Worker Twin leverages AI-powered simulations of human decision-making to optimize manufacturing processes in real-time. Integrating Cognitive Digital Worker Twins enhances operational efficiency by predicting system behaviors and enabling proactive problem-solving beyond traditional Kaizen methodologies.

Augmented Kaizen (AK)

Augmented Kaizen (AK) integrates Human Digital Twin technology to enhance continuous improvement processes in manufacturing by providing real-time data analytics and personalized performance feedback. This fusion accelerates decision-making, optimizes workflow efficiency, and drives adaptive innovations beyond traditional Kaizen methodologies.

Human-in-the-Loop Digital Kaizen

Human-in-the-Loop Digital Kaizen integrates Human Digital Twin technology to continuously optimize manufacturing processes by combining real-time human behavior data with AI-driven analytics, enabling adaptive and precise process improvements. This approach enhances traditional Kaizen by incorporating digital simulations of human operators, fostering dynamic feedback loops for increased efficiency and reduced errors on the production floor.

Kaizen vs Human Digital Twin Infographic

industrydif.com

industrydif.com