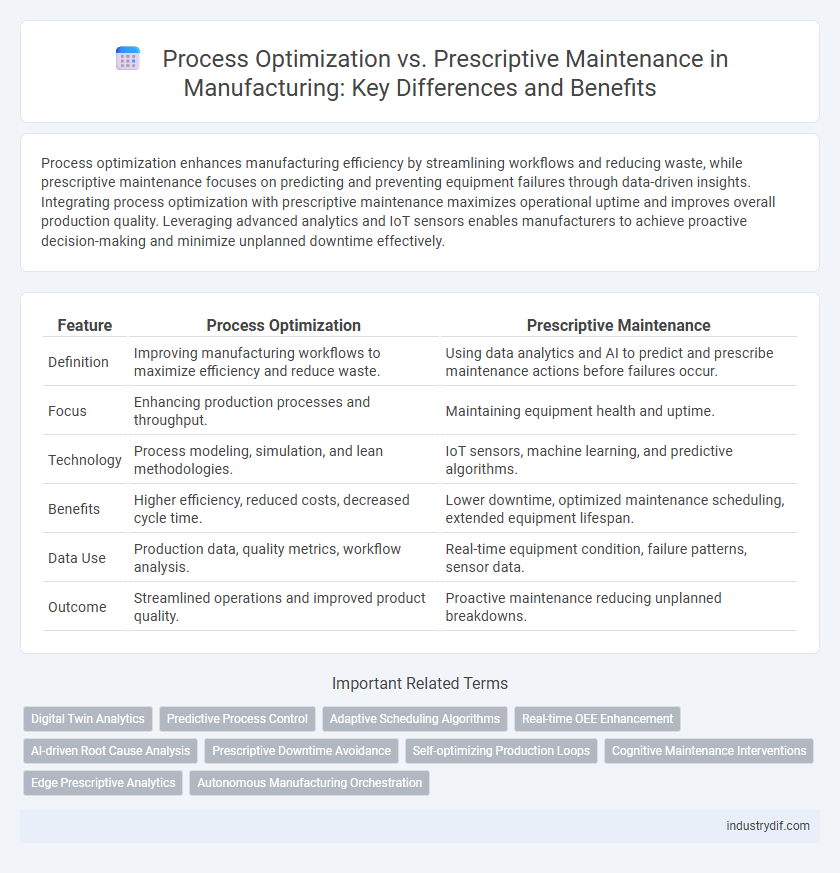

Process optimization enhances manufacturing efficiency by streamlining workflows and reducing waste, while prescriptive maintenance focuses on predicting and preventing equipment failures through data-driven insights. Integrating process optimization with prescriptive maintenance maximizes operational uptime and improves overall production quality. Leveraging advanced analytics and IoT sensors enables manufacturers to achieve proactive decision-making and minimize unplanned downtime effectively.

Table of Comparison

| Feature | Process Optimization | Prescriptive Maintenance |

|---|---|---|

| Definition | Improving manufacturing workflows to maximize efficiency and reduce waste. | Using data analytics and AI to predict and prescribe maintenance actions before failures occur. |

| Focus | Enhancing production processes and throughput. | Maintaining equipment health and uptime. |

| Technology | Process modeling, simulation, and lean methodologies. | IoT sensors, machine learning, and predictive algorithms. |

| Benefits | Higher efficiency, reduced costs, decreased cycle time. | Lower downtime, optimized maintenance scheduling, extended equipment lifespan. |

| Data Use | Production data, quality metrics, workflow analysis. | Real-time equipment condition, failure patterns, sensor data. |

| Outcome | Streamlined operations and improved product quality. | Proactive maintenance reducing unplanned breakdowns. |

Understanding Process Optimization in Manufacturing

Process optimization in manufacturing focuses on enhancing production efficiency by systematically analyzing and improving workflows, equipment performance, and resource utilization. Leveraging data analytics, machine learning, and real-time monitoring, process optimization identifies bottlenecks, reduces waste, and increases overall throughput. This approach ensures consistent product quality while minimizing operational costs and downtime.

Defining Prescriptive Maintenance and Its Role

Prescriptive maintenance uses advanced analytics, machine learning, and real-time data to predict equipment failures and recommend specific actions, optimizing manufacturing processes and reducing downtime. By integrating sensor data with historical performance metrics, it moves beyond traditional reactive or preventive maintenance to provide precise, actionable guidance for maintenance teams. This approach ensures higher equipment reliability, minimizes operational costs, and enhances overall production efficiency.

Key Objectives of Process Optimization

Process optimization in manufacturing targets maximizing efficiency, reducing waste, and improving product quality through data-driven adjustments in workflows and resource allocation. Key objectives include minimizing production cycle times, enhancing equipment utilization, and ensuring consistent output to meet demand. This approach leverages real-time analytics and machine learning to identify bottlenecks and optimize parameters throughout the manufacturing process.

Core Benefits of Prescriptive Maintenance

Prescriptive maintenance delivers core benefits by leveraging real-time data analytics and machine learning algorithms to predict equipment failures and recommend actionable maintenance steps, reducing unplanned downtime significantly. This proactive approach optimizes resource allocation, enhances asset lifespan, and increases overall production efficiency compared to traditional process optimization methods. Manufacturers benefit from cost savings and improved operational reliability through precise maintenance interventions driven by prescriptive insights.

Comparative Analysis: Efficiency Gains

Process optimization enhances manufacturing efficiency by systematically refining workflows and resource allocation, leading to reduced cycle times and minimized waste. Prescriptive maintenance improves operational uptime through predictive analytics and real-time monitoring, enabling proactive repairs that prevent costly breakdowns. Comparative analysis reveals that while process optimization boosts overall production speed, prescriptive maintenance drives substantial efficiency gains by directly minimizing unexpected equipment downtime.

Data Utilization in Process Optimization vs. Prescriptive Maintenance

Process optimization leverages real-time production data and advanced analytics to enhance manufacturing workflows, reduce waste, and increase throughput. Prescriptive maintenance utilizes sensor data and predictive algorithms to recommend specific maintenance actions that prevent equipment failures and minimize downtime. Both approaches depend heavily on accurate, high-velocity data streams but apply them differently to either refine operational efficiency or schedule proactive maintenance interventions.

Technology Integration: IoT, AI, and Automation

Process optimization leverages IoT sensors and AI analytics to continuously monitor manufacturing workflows, identifying inefficiencies and enabling real-time adjustments that enhance productivity. Prescriptive maintenance utilizes AI-driven predictive models and automated systems to forecast equipment failures, schedule timely interventions, and reduce downtime. Integrating IoT, AI, and automation creates a unified technology ecosystem that maximizes operational efficiency and prolongs machinery lifecycle in manufacturing environments.

Implementation Challenges and Solutions

Process optimization and prescriptive maintenance both enhance manufacturing efficiency but face distinct implementation challenges, such as integration complexity and data quality issues. Overcoming these obstacles requires adopting advanced analytics platforms, ensuring robust sensor data accuracy, and fostering cross-functional collaboration between IT and operations teams. Implementing scalable IoT infrastructure and continuous training programs accelerates adoption and maximizes return on investment in smart manufacturing technologies.

Measuring ROI for Both Approaches

Measuring ROI for process optimization involves evaluating improvements in throughput, reduced cycle times, and minimized waste, which directly impact production efficiency and cost savings. Prescriptive maintenance ROI is assessed through decreased downtime, extended equipment lifespan, and lower repair costs by using predictive analytics to schedule timely interventions. Comparing both approaches requires analyzing data on operational performance metrics, maintenance expenses, and overall impact on asset utilization to determine the most cost-effective strategy.

Future Trends in Manufacturing Optimization

Future trends in manufacturing optimization emphasize the integration of AI-driven process optimization with prescriptive maintenance to enhance operational efficiency and minimize downtime. Advanced data analytics and machine learning models enable real-time decision-making, predictive insights, and adaptive control systems that optimize production workflows and equipment health simultaneously. The convergence of IoT sensors, digital twins, and cloud computing forms the backbone of smart factories, driving continuous improvements in manufacturing performance and sustainability.

Related Important Terms

Digital Twin Analytics

Digital twin analytics enables real-time monitoring and simulation of manufacturing processes, driving process optimization by identifying inefficiencies and predicting system behavior. Prescriptive maintenance leverages these digital models to recommend specific actions that prevent equipment failures, minimizing downtime and extending asset life.

Predictive Process Control

Predictive Process Control leverages real-time data analytics and machine learning algorithms to optimize manufacturing operations by anticipating deviations and adjusting parameters proactively. Unlike prescriptive maintenance, which focuses on scheduling repairs to avoid downtime, process optimization integrates predictive insights directly into control systems to enhance efficiency, reduce waste, and improve product quality continuously.

Adaptive Scheduling Algorithms

Adaptive scheduling algorithms leverage real-time data to dynamically adjust manufacturing workflows, enhancing process optimization by minimizing downtime and resource wastage. Prescriptive maintenance integrates these algorithms to forecast equipment failures and optimize maintenance schedules, improving overall operational efficiency and asset longevity.

Real-time OEE Enhancement

Process optimization in manufacturing leverages real-time data analytics to continuously improve equipment efficiency and throughput, directly enhancing Overall Equipment Effectiveness (OEE). Prescriptive maintenance uses advanced algorithms and sensor data to predict failures and recommend precise actions, minimizing downtime and supporting sustained OEE improvements.

AI-driven Root Cause Analysis

AI-driven root cause analysis enhances process optimization by quickly identifying inefficiencies and defects in manufacturing workflows, reducing downtime and operational costs. Prescriptive maintenance leverages this analysis to predict equipment failures and recommend precise interventions, ensuring continuous production and maximizing asset lifespan.

Prescriptive Downtime Avoidance

Prescriptive Maintenance leverages real-time data analytics and machine learning algorithms to predict equipment failures and recommend precise actions, significantly minimizing unplanned downtime in manufacturing processes. Unlike general process optimization, prescriptive downtime avoidance ensures targeted interventions that enhance operational efficiency, reduce maintenance costs, and increase overall equipment effectiveness (OEE).

Self-optimizing Production Loops

Self-optimizing production loops enhance process optimization by continuously analyzing real-time manufacturing data to adjust parameters for maximum efficiency and quality output. Prescriptive maintenance complements these loops by predicting equipment failures and recommending precise interventions, minimizing downtime and ensuring uninterrupted production flow.

Cognitive Maintenance Interventions

Cognitive maintenance interventions enhance manufacturing efficiency by integrating process optimization with prescriptive maintenance, using AI-driven insights to predict equipment failures and recommend targeted actions. This synergy reduces downtime, extends asset lifespan, and drives proactive decision-making within smart factories.

Edge Prescriptive Analytics

Edge prescriptive analytics enhances manufacturing process optimization by delivering real-time, data-driven maintenance recommendations directly at the equipment level, reducing downtime and increasing operational efficiency. Implementing these analytics enables predictive adjustments and prescriptive actions that extend asset life and improve overall production quality compared to traditional preventive maintenance strategies.

Autonomous Manufacturing Orchestration

Process optimization employs real-time data analytics and machine learning algorithms to enhance production efficiency and reduce operational costs, while prescriptive maintenance leverages predictive insights to schedule timely equipment repairs, minimizing downtime. Autonomous manufacturing orchestration integrates both strategies by automating decision-making workflows, ensuring seamless coordination between process adjustments and maintenance actions to maximize overall asset utilization.

Process Optimization vs Prescriptive Maintenance Infographic

industrydif.com

industrydif.com