Mass production enables large-scale manufacturing of standardized products, driving down costs through economies of scale and streamlining assembly lines for maximum efficiency. Microfactories offer flexible, localized production with rapid customization capabilities, minimizing inventory and reducing lead times for niche markets. Balancing mass production's volume benefits with microfactories' agility allows manufacturers to optimize output while meeting diverse consumer demands.

Table of Comparison

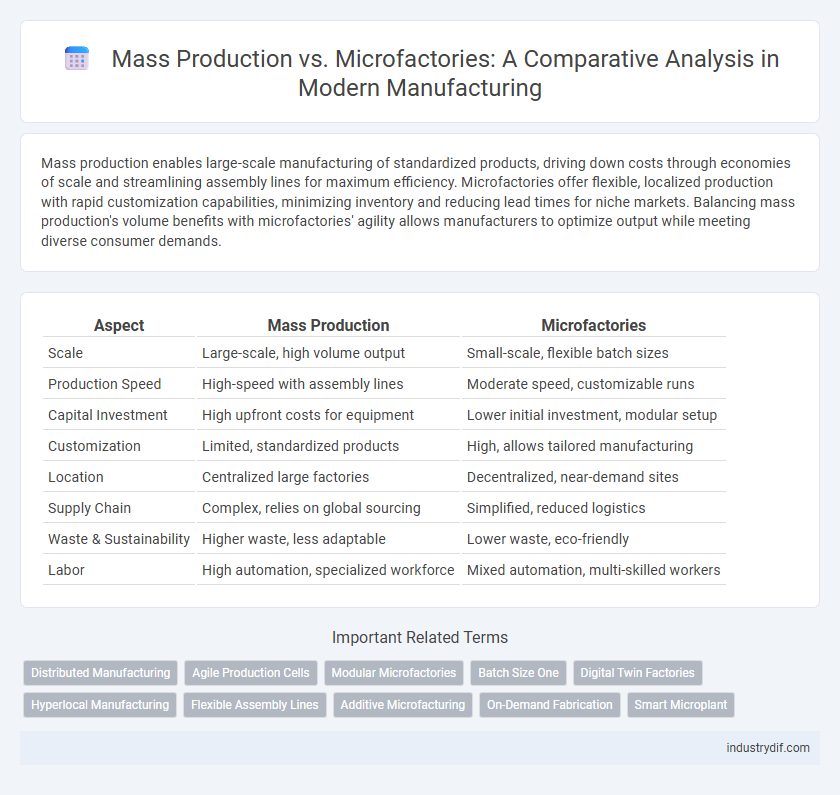

| Aspect | Mass Production | Microfactories |

|---|---|---|

| Scale | Large-scale, high volume output | Small-scale, flexible batch sizes |

| Production Speed | High-speed with assembly lines | Moderate speed, customizable runs |

| Capital Investment | High upfront costs for equipment | Lower initial investment, modular setup |

| Customization | Limited, standardized products | High, allows tailored manufacturing |

| Location | Centralized large factories | Decentralized, near-demand sites |

| Supply Chain | Complex, relies on global sourcing | Simplified, reduced logistics |

| Waste & Sustainability | Higher waste, less adaptable | Lower waste, eco-friendly |

| Labor | High automation, specialized workforce | Mixed automation, multi-skilled workers |

Introduction to Mass Production and Microfactories

Mass production involves large-scale manufacturing processes that produce standardized products using assembly lines and automation, optimizing efficiency and cost-effectiveness. Microfactories are small-scale, flexible facilities designed for localized production, enabling customization and faster response to market demands. Both approaches leverage technology but differ significantly in scale, output volume, and adaptability to changing consumer needs.

Key Differences: Scale and Flexibility

Mass production operates on a large scale, producing standardized products with high efficiency and low unit costs, ideal for meeting extensive market demands. Microfactories emphasize flexibility with compact, modular setups enabling rapid customization and localized manufacturing, catering to niche markets and reducing lead times. The key difference lies in scale, where mass production prioritizes volume, while microfactories focus on adaptability and responsiveness to changing customer needs.

Historical Evolution of Manufacturing Models

Mass production revolutionized manufacturing in the early 20th century by introducing assembly lines and standardized parts, drastically reducing costs and production time. Microfactories emerged as a flexible alternative in the 21st century, emphasizing localized, small-scale production with advanced automation and customization capabilities. This shift reflects an evolution from centralized, high-volume manufacturing to decentralized, agile models driven by digital technology and consumer demand for personalized products.

Efficiency and Cost Implications

Mass production achieves high efficiency through large-scale, standardized processes that lower per-unit costs but often require substantial initial capital investment and inflexible production lines. Microfactories optimize cost by utilizing advanced automation and modular designs, enabling rapid customization and reduced inventory expenses while maintaining lower overhead. Efficiency in microfactories stems from localized manufacturing with reduced transportation costs, contrasting mass production's economies of scale that favor volume over adaptability.

Customization Capabilities in Modern Manufacturing

Mass production excels in delivering high volumes of standardized products with limited customization, relying on assembly line efficiency and economies of scale. Microfactories leverage advanced technologies like additive manufacturing and modular equipment to enable rapid, cost-effective customization for niche markets. This shift enhances manufacturers' ability to respond to specific consumer demands, driving innovation and flexibility in modern production processes.

Environmental Impact and Sustainability

Mass production typically involves large-scale manufacturing processes that consume substantial energy and generate significant waste, contributing to environmental degradation. Microfactories offer a sustainable alternative by utilizing compact, energy-efficient technologies that reduce material waste and carbon emissions while enabling localized production. This shift supports circular economy principles and minimizes transportation-related pollution, enhancing overall environmental sustainability in manufacturing.

Technology Integration: Automation and Digitalization

Mass production relies heavily on advanced automation systems and robotics to achieve high-volume output with consistent quality, while microfactories integrate digital technologies such as IoT sensors, AI-driven analytics, and flexible automation to enhance customization and rapid response. Automation in mass production focuses on efficiency and speed through standardized processes, whereas microfactories leverage digitalization for real-time monitoring and adaptive manufacturing workflows. The convergence of automation and digitalization in both models drives innovation in manufacturing, but microfactories emphasize technology integration for agility and decentralization.

Supply Chain Dynamics and Localized Production

Mass production relies on centralized factories with extensive supply chains, often causing delays and higher transportation costs due to long-distance shipping. Microfactories enable localized production, reducing lead times and enhancing supply chain resilience by sourcing materials closer to the point of manufacture. This shift supports just-in-time inventory strategies and minimizes the carbon footprint associated with traditional manufacturing logistics.

Quality Control and Product Consistency

Mass production excels in maintaining product consistency through standardized processes and rigorous quality control systems, enabling high-volume output with minimal variation. Microfactories offer enhanced quality control at a smaller scale by allowing real-time monitoring and swift adjustments, reducing defects and customization errors. Balancing mass production's efficiency with microfactories' precision supports superior product consistency across diverse manufacturing environments.

Future Trends: Hybrid Approaches and Industry 4.0

Mass production integrates with microfactories through hybrid approaches leveraging Industry 4.0 technologies such as IoT, AI, and robotics to enhance flexibility and customization while maintaining high output. Smart factories utilize real-time data analytics and digital twins to optimize supply chains and reduce downtime, driving efficiency and sustainability. The convergence of large-scale production with decentralized microfactories enables responsive manufacturing ecosystems tailored to dynamic market demands.

Related Important Terms

Distributed Manufacturing

Mass production centralizes large-scale manufacturing in a single location to maximize efficiency, while microfactories leverage distributed manufacturing by placing smaller, flexible production units closer to end-users, reducing lead times and lowering transportation costs. Distributed manufacturing enhances supply chain resilience, supports customization, and enables rapid response to market demand fluctuations through localized and scalable production hubs.

Agile Production Cells

Agile production cells within microfactories enable flexible, decentralized manufacturing processes that significantly reduce lead times and improve customization compared to traditional mass production lines. These cells integrate automation and skilled labor to swiftly adapt to changing demand, enhancing efficiency while minimizing waste and inventory costs.

Modular Microfactories

Modular microfactories revolutionize mass production by offering scalable, adaptable manufacturing units that reduce setup time and overhead costs while maintaining high output efficiency. These compact, reconfigurable systems enable localized production, enhance supply chain resilience, and support customization without sacrificing the principles of mass manufacturing.

Batch Size One

Mass production excels at large-scale output with uniform products, but struggles with customization and efficiency for batch size one orders. Microfactories leverage flexible, automated systems and localized production, enabling cost-effective, scalable manufacturing tailored to unique, single-unit demands.

Digital Twin Factories

Digital Twin Factories enable real-time simulation and optimization in both mass production and microfactory models, enhancing efficiency and reducing downtime. By integrating IoT sensors and AI analytics, these digital replicas facilitate adaptive manufacturing processes, supporting scalable output in large-scale plants and customized agility in smaller microfactories.

Hyperlocal Manufacturing

Mass production concentrates on large-scale, centralized factories to manufacture standardized goods at low cost, while microfactories emphasize hyperlocal manufacturing with smaller, agile facilities that reduce transportation emissions and enable rapid customization. Hyperlocal manufacturing through microfactories leverages advanced automation and digital technologies to enhance supply chain resilience and meet local market demands efficiently.

Flexible Assembly Lines

Flexible assembly lines in microfactories enable rapid customization and scalability, contrasting mass production's rigid, high-volume processes. This adaptability reduces lead times and minimizes inventory costs, enhancing responsiveness to market fluctuations in manufacturing.

Additive Microfacturing

Mass production relies on large-scale, standardized manufacturing processes to achieve economies of scale, whereas additive microfacturing emphasizes precision and customization through layer-by-layer 3D printing technologies, enabling rapid prototyping and localized production. Additive microfacturing reduces material waste and shortens supply chains by producing complex components on-demand within compact, modular microfactories.

On-Demand Fabrication

Mass production offers economies of scale by producing large quantities of standardized products, but often results in excess inventory and limited customization options. Microfactories enable on-demand fabrication with flexible, localized manufacturing processes that reduce lead times, minimize waste, and allow for tailored production to meet dynamic market demands.

Smart Microplant

Smart microplants leverage advanced automation and IoT integration to enable flexible mass production with reduced overhead and shorter lead times compared to traditional large-scale manufacturing. These intelligent microfactories optimize resource utilization and real-time data analytics, driving efficiency and customization in high-volume production environments.

Mass Production vs Microfactories Infographic

industrydif.com

industrydif.com