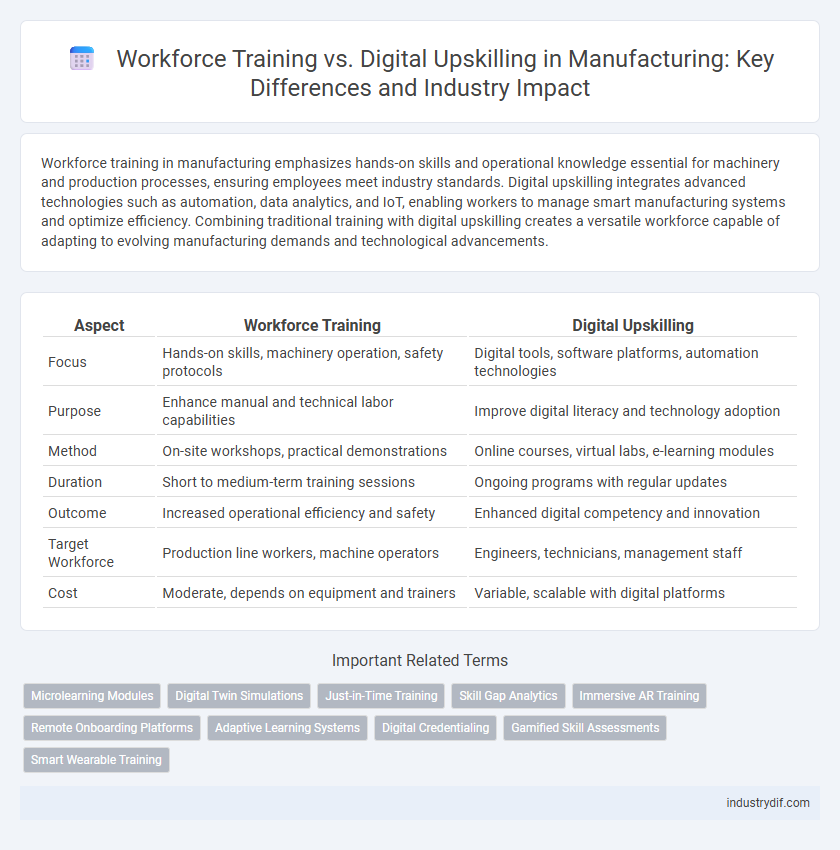

Workforce training in manufacturing emphasizes hands-on skills and operational knowledge essential for machinery and production processes, ensuring employees meet industry standards. Digital upskilling integrates advanced technologies such as automation, data analytics, and IoT, enabling workers to manage smart manufacturing systems and optimize efficiency. Combining traditional training with digital upskilling creates a versatile workforce capable of adapting to evolving manufacturing demands and technological advancements.

Table of Comparison

| Aspect | Workforce Training | Digital Upskilling |

|---|---|---|

| Focus | Hands-on skills, machinery operation, safety protocols | Digital tools, software platforms, automation technologies |

| Purpose | Enhance manual and technical labor capabilities | Improve digital literacy and technology adoption |

| Method | On-site workshops, practical demonstrations | Online courses, virtual labs, e-learning modules |

| Duration | Short to medium-term training sessions | Ongoing programs with regular updates |

| Outcome | Increased operational efficiency and safety | Enhanced digital competency and innovation |

| Target Workforce | Production line workers, machine operators | Engineers, technicians, management staff |

| Cost | Moderate, depends on equipment and trainers | Variable, scalable with digital platforms |

Understanding Workforce Training in Manufacturing

Workforce training in manufacturing involves hands-on skill development essential for operating machinery, adhering to safety protocols, and maintaining production efficiency. Emphasizing practical knowledge transfer ensures employees meet industry standards and reduce errors on the shop floor. This foundational training contrasts with digital upskilling, which incorporates advanced technologies like IoT and automation for enhanced operational capabilities.

Defining Digital Upskilling for Modern Factories

Digital upskilling in modern factories involves equipping the workforce with advanced technological skills such as data analytics, IoT integration, and automation control to enhance operational efficiency. Unlike traditional workforce training, which often emphasizes manual skills and safety protocols, digital upskilling prepares employees to handle smart manufacturing systems and real-time data interpretation. This targeted improvement in digital competencies drives productivity, reduces downtime, and supports the seamless adoption of Industry 4.0 technologies in manufacturing environments.

Key Differences: Traditional Training vs. Digital Upskilling

Workforce training in manufacturing typically emphasizes hands-on, classroom-based instruction focused on machinery operation and safety protocols, while digital upskilling prioritizes proficiency in advanced technologies such as IoT, AI, and data analytics essential for smart manufacturing. Traditional training often relies on fixed curricula and instructor-led sessions, whereas digital upskilling embraces adaptive, online platforms enabling continuous learning and real-time problem-solving. The shift towards digital upskilling addresses the industry's demand for agile workers capable of leveraging automation and digital tools to enhance productivity and innovation.

The Role of Technology in Shaping Manufacturing Skills

Technology drives the evolution of manufacturing skills by integrating digital tools such as AI, IoT, and robotics into workforce training programs. Digital upskilling focuses on enhancing competencies in data analysis, automation, and machine learning to meet the demands of Industry 4.0. Manufacturing companies adopting advanced simulation software and virtual reality for training see increased productivity and reduced downtime by equipping employees with hands-on digital experience.

Benefits of Digital Upskilling in Manufacturing Operations

Digital upskilling in manufacturing operations enhances workforce adaptability by integrating advanced technologies such as IoT, AI, and automation into daily processes, resulting in increased productivity and reduced downtime. Skilled employees equipped with digital competencies improve quality control through real-time data analysis and predictive maintenance, minimizing errors and operational costs. This targeted development fosters innovation and accelerates the adoption of Industry 4.0 standards, driving competitive advantage and sustainable growth in manufacturing facilities.

Overcoming Barriers to Workforce Training Adoption

Overcoming barriers to workforce training adoption in manufacturing requires addressing resistance to change, limited access to technology, and skill gaps through practical, hands-on learning and accessible digital tools. Integrating digital upskilling with traditional training enables employees to adapt rapidly to advanced manufacturing technologies, improving productivity and operational efficiency. Customized training programs that align with specific job roles help bridge knowledge gaps while fostering a culture of continuous learning and innovation.

Aligning Training Strategies with Industry 4.0 Demands

Workforce training in manufacturing must evolve to include digital upskilling, targeting competencies like IoT integration, data analytics, and automation to meet Industry 4.0 demands. Aligning training strategies with advanced technologies accelerates operational efficiency and fosters innovation across smart factories. Emphasizing continuous learning and adaptive skill development ensures a resilient workforce equipped for digital transformation challenges.

Measuring ROI: Workforce Training vs Digital Upskilling

Measuring ROI in workforce training versus digital upskilling requires analyzing productivity gains, employee retention rates, and skill proficiency improvements specific to manufacturing operations. Digital upskilling often delivers faster, quantifiable returns through technology adoption metrics and reduced downtime, while traditional workforce training enhances foundational skills critical for long-term operational efficiency. Combining data from performance dashboards and employee feedback tools enables manufacturers to optimize investment strategies for both training types.

Case Studies: Successful Upskilling in Manufacturing

Case studies in manufacturing highlight the impact of workforce training programs that integrate traditional hands-on skills with digital upskilling in areas like CNC programming and IoT device management. Companies such as Siemens and Bosch report increased productivity and reduced downtime after implementing blended training approaches combining AR-based simulations and real-time data analytics training. These successful upskilling initiatives demonstrate measurable improvements in operator efficiency, quality control, and adaptability to Industry 4.0 technologies.

Future Trends in Manufacturing Workforce Development

Workforce training in manufacturing increasingly integrates digital upskilling to meet evolving demands of Industry 4.0, emphasizing proficiency in automation, IoT, and AI technologies. Future trends highlight augmented reality (AR) and virtual reality (VR) as immersive platforms for hands-on skill development, enhancing operator efficiency and machine interaction. Employers prioritize continuous learning ecosystems that blend traditional manufacturing skills with digital competencies to sustain competitive advantage and innovation.

Related Important Terms

Microlearning Modules

Microlearning modules in manufacturing provide targeted workforce training by delivering concise, skill-specific content that enhances retention and accelerates competency development. Digital upskilling through these modules leverages interactive technologies and real-time feedback to adapt to individual learning paces, driving productivity and reducing skill gaps on the factory floor.

Digital Twin Simulations

Workforce training in manufacturing enhances hands-on skills and process understanding, while digital upskilling through digital twin simulations enables real-time virtual modeling of production environments to optimize operations and reduce downtime. Integrating digital twins accelerates skill acquisition by providing immersive, data-driven scenarios that improve decision-making and operational efficiency.

Just-in-Time Training

Just-in-Time Training delivers targeted workforce training by providing manufacturing employees with immediate, role-specific digital upskilling resources that enhance productivity and reduce downtime. Integrating digital tools like augmented reality and AI-driven modules ensures precise skill acquisition aligned with real-time operational needs, optimizing manufacturing efficiency.

Skill Gap Analytics

Skill gap analytics in manufacturing reveals critical disparities between existing workforce capabilities and evolving digital technology demands, guiding targeted workforce training programs. Digital upskilling leverages real-time data insights to customize learning paths, enhancing employee adaptability and closing skill gaps faster than traditional training methods.

Immersive AR Training

Immersive AR training enhances workforce capabilities by providing hands-on, interactive simulations that accelerate skill acquisition and reduce training time in manufacturing environments. This digital upskilling approach improves operational efficiency and safety by enabling employees to practice complex tasks in a controlled, virtual setting before applying them on the shop floor.

Remote Onboarding Platforms

Remote onboarding platforms enhance workforce training by delivering interactive modules and real-time feedback tailored to manufacturing processes, significantly reducing ramp-up time for new hires. Digital upskilling through these platforms enables continuous skill development in advanced technologies such as IoT, robotics, and AI, driving operational efficiency and agility in manufacturing environments.

Adaptive Learning Systems

Adaptive learning systems revolutionize workforce training in manufacturing by personalizing skill development through real-time data analysis and AI-driven content delivery, resulting in faster proficiency and reduced downtime. These systems effectively bridge the gap between traditional workforce training and digital upskilling by continuously adjusting to individual learning paces and evolving industry requirements.

Digital Credentialing

Digital credentialing in manufacturing enhances workforce training by providing verifiable, skill-specific certifications that streamline employee assessment and career progression. This approach accelerates digital upskilling, ensuring workers meet evolving industry 4.0 standards through targeted, competency-based learning modules.

Gamified Skill Assessments

Gamified skill assessments enhance workforce training in manufacturing by providing interactive, engaging evaluations that improve digital upskilling effectiveness and employee retention. These assessments leverage real-time data analytics to identify skill gaps, personalize learning paths, and accelerate competency development in critical manufacturing technologies.

Smart Wearable Training

Smart wearable training in manufacturing enhances workforce training by providing real-time data analytics and hands-free learning experiences, improving skill acquisition and reducing errors on the production floor. Digital upskilling through these devices accelerates employee adaptation to Industry 4.0 technologies, boosting overall operational efficiency and safety compliance.

Workforce Training vs Digital Upskilling Infographic

industrydif.com

industrydif.com