CNC machining offers precise, computer-controlled metalworking ideal for prototyping and custom parts production, emphasizing accuracy and repeatability. Cloud manufacturing integrates digital platforms to optimize resource sharing, real-time collaboration, and scalable production, enhancing operational efficiency across distributed facilities. Combining CNC machining with cloud manufacturing enables seamless data exchange and accelerated innovation in smart manufacturing environments.

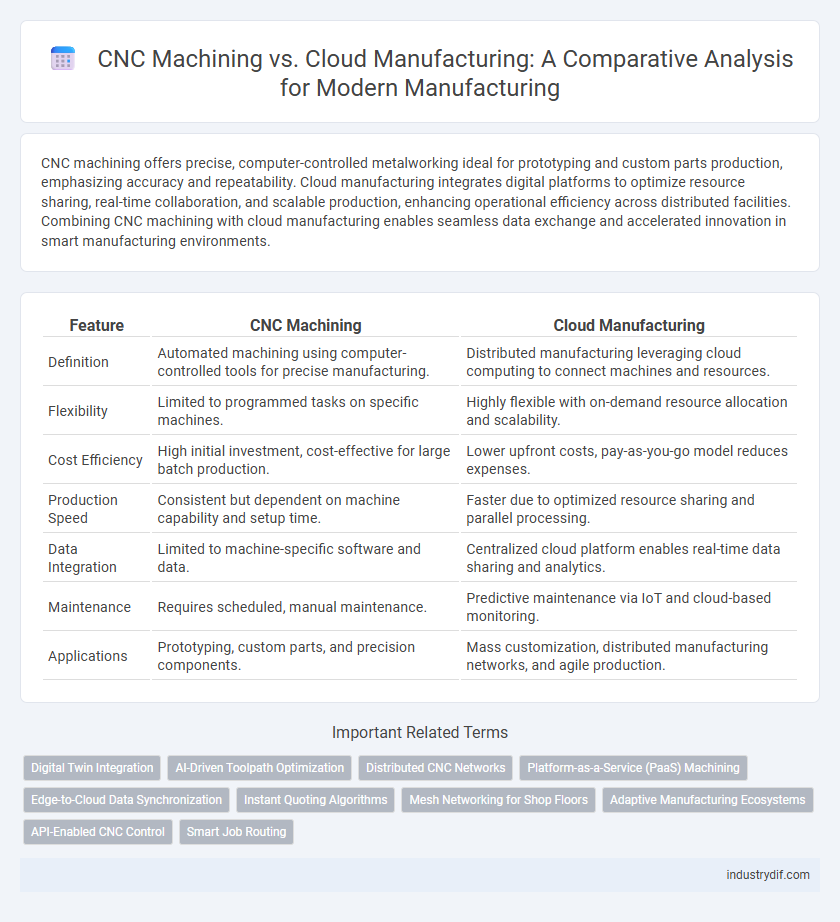

Table of Comparison

| Feature | CNC Machining | Cloud Manufacturing |

|---|---|---|

| Definition | Automated machining using computer-controlled tools for precise manufacturing. | Distributed manufacturing leveraging cloud computing to connect machines and resources. |

| Flexibility | Limited to programmed tasks on specific machines. | Highly flexible with on-demand resource allocation and scalability. |

| Cost Efficiency | High initial investment, cost-effective for large batch production. | Lower upfront costs, pay-as-you-go model reduces expenses. |

| Production Speed | Consistent but dependent on machine capability and setup time. | Faster due to optimized resource sharing and parallel processing. |

| Data Integration | Limited to machine-specific software and data. | Centralized cloud platform enables real-time data sharing and analytics. |

| Maintenance | Requires scheduled, manual maintenance. | Predictive maintenance via IoT and cloud-based monitoring. |

| Applications | Prototyping, custom parts, and precision components. | Mass customization, distributed manufacturing networks, and agile production. |

Overview of CNC Machining and Cloud Manufacturing

CNC machining involves automated control of machine tools through computer programming, enabling precise and repeatable manufacturing of complex parts from metal, plastic, and other materials. Cloud manufacturing leverages internet-based platforms to connect services, resources, and production facilities, facilitating scalable and flexible manufacturing operations with real-time data sharing and collaboration. While CNC machining emphasizes localized, high-precision fabrication, cloud manufacturing integrates distributed manufacturing capabilities to optimize supply chains and reduce lead times.

Core Principles: Traditional vs. Digital Manufacturing

CNC machining relies on precise, computer-controlled cutting tools operating on physical materials to produce components with high accuracy, emphasizing hardware-centric processes. Cloud manufacturing integrates digital technologies and IoT to enable real-time data sharing, remote monitoring, and collaborative production workflows via internet-connected platforms. This shift from traditional CNC's isolated machine control to cloud-based, adaptive manufacturing leverages scalability, flexibility, and resource optimization across distributed factories.

Workflow Comparison: CNC Machining vs. Cloud Platforms

CNC machining relies on a traditional, linear workflow where design files are manually programmed into machines, requiring skilled operators to execute precise, physical operations and machine setup. Cloud manufacturing platforms streamline this process by integrating digital design, simulation, and production management tools into a single online environment, enabling real-time collaboration, remote monitoring, and automated job scheduling. This shift from isolated CNC workflows to interconnected cloud-based systems significantly enhances operational efficiency, scalability, and data-driven decision-making in manufacturing.

Scalability and Flexibility in Production

CNC machining offers high precision and consistency in manufacturing but is often limited by fixed machine capacity and setup times, affecting scalability during demand fluctuations. Cloud manufacturing leverages IoT integration and distributed manufacturing resources, enabling real-time scalability and flexibility by dynamically allocating production tasks across multiple facilities. This model supports rapid adjustments to production volume and customization, enhancing responsiveness to market changes without significant capital investment.

Cost Structure: Upfront Investment vs. Subscription Models

CNC machining requires significant upfront investment in specialized hardware, tooling, and maintenance, driving higher initial capital expenditure for manufacturers. Cloud manufacturing operates on subscription models, distributing costs over time and reducing barriers for small and medium enterprises by eliminating large upfront expenses. This shift in cost structure enables greater flexibility, scalability, and cost predictability within modern manufacturing strategies.

Integration with Industry 4.0 Initiatives

CNC machining drives precision manufacturing through automated control of machine tools, while cloud manufacturing leverages networked resources for scalable production management. Integration with Industry 4.0 initiatives enhances CNC systems by embedding IoT sensors and real-time data analytics for predictive maintenance and process optimization. Cloud manufacturing platforms amplify Industry 4.0 benefits by enabling seamless collaboration, digital twin simulations, and big data integration across distributed manufacturing networks.

Quality Control and Precision Standards

CNC machining ensures high precision and consistent quality control through rigid adherence to ISO 9001 standards and real-time monitoring of tool performance and material tolerances. Cloud manufacturing integrates advanced data analytics and IoT sensors to enhance quality control by predicting maintenance needs and reducing human error in production processes. Both methods prioritize precision, but cloud manufacturing offers scalable improvements via continuous data feedback loops and adaptive process optimization.

Data Security and IP Protection

CNC machining relies on localized control systems, limiting exposure to external cyber threats, which enhances data security and IP protection compared to cloud-based solutions. Cloud manufacturing introduces risks of data breaches since sensitive design files and process parameters are stored and transmitted over the internet. Implementing robust encryption protocols and access controls is critical to safeguard intellectual property in cloud manufacturing environments.

Supply Chain and Lead Time Optimization

CNC machining offers precise, on-demand production but often faces limitations in scalability and longer lead times due to localized equipment and workforce constraints. Cloud manufacturing integrates distributed resources and real-time data sharing across the supply chain, enabling dynamic load balancing and significant lead time reductions through enhanced flexibility and collaboration. This digital approach optimizes inventory management and accelerates order fulfillment, improving overall supply chain responsiveness and efficiency in manufacturing operations.

Future Trends: Evolving Capabilities in Smart Manufacturing

CNC machining continues to advance with integration of AI-driven precision controls and real-time analytics that enhance production efficiency and accuracy. Cloud manufacturing leverages IoT connectivity and big data to enable distributed production networks and adaptive supply chain management. Future trends highlight a convergence of these technologies, creating intelligent, flexible factories with predictive maintenance and autonomous decision-making capabilities.

Related Important Terms

Digital Twin Integration

CNC machining leverages precise computer-controlled tools for manufacturing physical components, while cloud manufacturing incorporates digital twin integration to enable real-time monitoring, simulation, and optimization of production processes. Digital twins create virtual replicas of CNC operations, enhancing predictive maintenance and reducing downtime through continuous data synchronization in cloud environments.

AI-Driven Toolpath Optimization

AI-driven toolpath optimization in CNC machining leverages machine learning algorithms to enhance precision, reduce cycle times, and minimize material waste, significantly boosting manufacturing efficiency. Cloud manufacturing integrates this AI capability by enabling real-time data analysis and remote collaboration, streamlining production workflows and accelerating decision-making processes.

Distributed CNC Networks

Distributed CNC networks enable seamless integration of CNC machining processes across multiple geographic locations, enhancing production flexibility and reducing lead times. Cloud manufacturing platforms optimize resource allocation and real-time monitoring, driving efficiency and scalability in complex manufacturing environments.

Platform-as-a-Service (PaaS) Machining

Platform-as-a-Service (PaaS) Machining in cloud manufacturing enables on-demand access to CNC machining resources, optimizing production scalability and reducing capital expenditure compared to traditional CNC machining setups. This integration facilitates real-time collaboration, automated workflow management, and enhanced data analytics, driving efficiency and innovation across manufacturing operations.

Edge-to-Cloud Data Synchronization

Edge-to-cloud data synchronization in CNC machining enables real-time monitoring and precise control by transmitting machine operational data directly from the edge devices to centralized cloud platforms. Cloud manufacturing leverages this seamless data synchronization to optimize production workflows, enhance predictive maintenance, and improve overall equipment efficiency through advanced analytics and scalable cloud resources.

Instant Quoting Algorithms

Instant quoting algorithms in CNC machining enable rapid cost estimation based on precise material, tool path, and machine parameters, significantly reducing lead times for custom parts. Cloud manufacturing leverages these algorithms through interconnected digital platforms, allowing real-time collaboration and instant quotes across distributed production networks, optimizing efficiency and resource allocation.

Mesh Networking for Shop Floors

Mesh networking enhances CNC machining on shop floors by enabling decentralized communication among multiple machines, which boosts real-time data exchange and reduces downtime. Cloud manufacturing leverages mesh networks to integrate CNC machines into a flexibly connected system, improving operational efficiency and facilitating scalable production management.

Adaptive Manufacturing Ecosystems

CNC machining relies on precise, computer-controlled tooling for metal and plastic fabrication, emphasizing repeatability and accuracy in traditional manufacturing setups. Cloud manufacturing leverages adaptive manufacturing ecosystems by integrating IoT, AI, and real-time data analytics to enable flexible, scalable production across distributed facilities.

API-Enabled CNC Control

API-enabled CNC control integrates traditional CNC machining with cloud manufacturing platforms, enabling seamless remote operation, real-time monitoring, and data exchange. This connectivity enhances production efficiency, precision, and scalability by leveraging cloud-based analytics and automation in manufacturing workflows.

Smart Job Routing

Smart Job Routing in CNC machining leverages real-time data and machine capabilities to optimize tool paths and reduce idle time, enhancing production efficiency and precision. Cloud manufacturing extends this concept by integrating distributed CNC resources through digital platforms, enabling dynamic job allocation based on capacity, skill sets, and location for scalable and flexible manufacturing solutions.

CNC Machining vs Cloud Manufacturing Infographic

industrydif.com

industrydif.com