Mass production relies on large-scale assembly lines to manufacture standardized products efficiently, reducing cost per unit through economies of scale. Microfactories prioritize flexibility and customization, utilizing compact, automated systems to produce smaller batches tailored to specific market demands. Companies must balance the cost benefits of mass production with the agile innovation enabled by microfactories to optimize supply chain responsiveness.

Table of Comparison

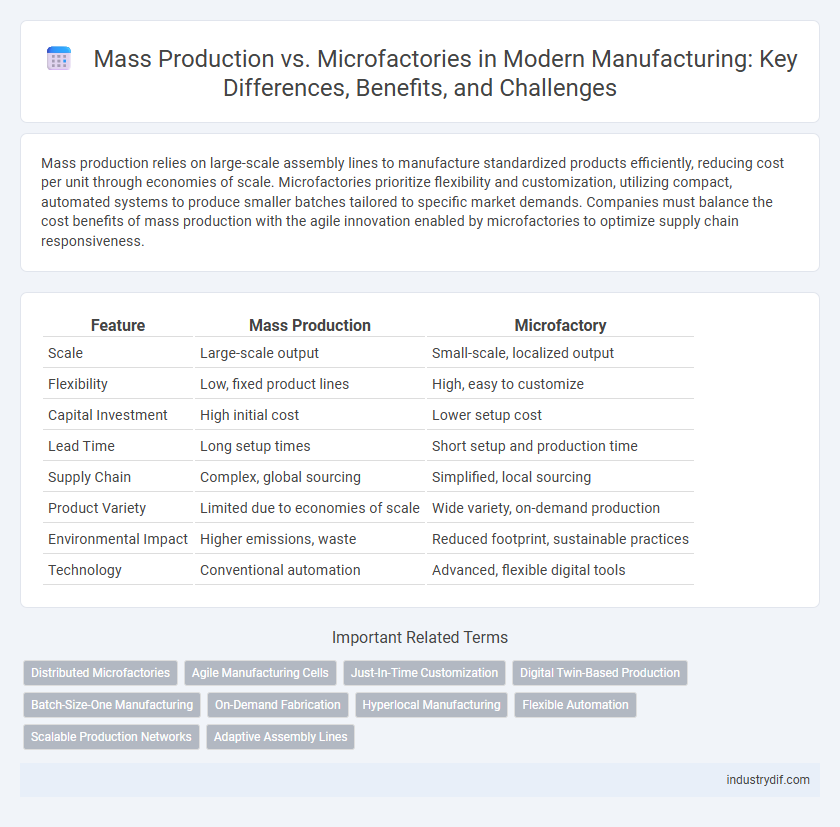

| Feature | Mass Production | Microfactory |

|---|---|---|

| Scale | Large-scale output | Small-scale, localized output |

| Flexibility | Low, fixed product lines | High, easy to customize |

| Capital Investment | High initial cost | Lower setup cost |

| Lead Time | Long setup times | Short setup and production time |

| Supply Chain | Complex, global sourcing | Simplified, local sourcing |

| Product Variety | Limited due to economies of scale | Wide variety, on-demand production |

| Environmental Impact | Higher emissions, waste | Reduced footprint, sustainable practices |

| Technology | Conventional automation | Advanced, flexible digital tools |

Introduction to Mass Production and Microfactories

Mass production involves large-scale manufacturing of standardized products using assembly lines and automated processes to achieve high volume efficiency and cost reduction. Microfactories are compact, flexible manufacturing units designed to produce smaller batches with customization, leveraging advanced technologies like robotics and IoT. Both methods aim to optimize production, where mass production excels in scale and microfactories offer agility and localized manufacturing.

Key Differences Between Mass Production and Microfactory Models

Mass production utilizes large-scale assembly lines to produce high volumes of standardized products, achieving economies of scale and lower unit costs. Microfactories operate on a smaller scale with flexible, modular equipment enabling customizable and rapid production runs tailored to local markets. Key differences include scale, customization capability, supply chain complexity, and capital investment requirements.

Historical Evolution of Manufacturing Approaches

Mass production emerged in the early 20th century with Henry Ford's assembly line revolutionizing manufacturing by enabling large-scale, cost-efficient output of standardized products. The late 20th and early 21st centuries saw the rise of microfactories, leveraging digital technologies, automation, and flexible manufacturing systems to produce customized, small-batch products closer to consumers. This shift reflects an evolution from centralized, high-volume production toward decentralized, agile manufacturing models that prioritize responsiveness and sustainability.

Scalability and Flexibility in Production

Mass production excels in scalability, enabling large volumes of uniform products through standardized processes, but often lacks flexibility to adapt quickly to design changes or customization. Microfactories emphasize flexibility with modular equipment and localized production, allowing rapid shifts in product lines and personalized manufacturing, though their scalability is limited compared to traditional mass production. Balancing scalability and flexibility is critical for manufacturers seeking efficient high-volume output alongside responsiveness to market demands and innovation.

Cost Structures: Mass Production vs Microfactory

Mass production leverages economies of scale by utilizing large-scale machinery and standardized processes, resulting in lower unit costs but significant upfront capital investment and high fixed costs. Microfactories emphasize flexibility and smaller batch production with lower initial capital requirements, leading to higher per-unit costs but reduced risk and operational expenses. Cost structures in mass production favor volume efficiency, whereas microfactories prioritize adaptability and localized manufacturing economics.

Impact on Customization and Product Variety

Mass production enables high-volume output with standardized products, limiting customization and reducing product variety due to fixed assembly lines. Microfactories leverage flexible manufacturing technologies and automation, allowing rapid adjustments for personalized products and increased variety without significant cost increases. This shift supports niche markets and consumer demand for customized goods while maintaining efficient production cycles.

Technology Integration in Modern Manufacturing

Advanced automation and IoT (Internet of Things) technologies drive efficiency in mass production, enabling high-volume output with consistent quality at reduced costs. Microfactories leverage AI-powered robotics and digital twins for flexible, localized manufacturing that quickly adapts to market demands and customization trends. Integration of real-time data analytics and machine learning optimizes both production scales, enhancing predictive maintenance and minimizing downtime in modern manufacturing environments.

Environmental and Sustainability Considerations

Mass production often leads to significant environmental impacts due to high energy consumption and large-scale waste generation, challenging sustainability efforts. Microfactories reduce carbon footprints by utilizing localized, energy-efficient operations and enabling circular manufacturing processes with minimal material waste. Sustainable manufacturing increasingly favors microfactory models to optimize resource use and lower environmental degradation while meeting market demands.

Case Studies: Success Stories in Mass Production and Microfactories

Case studies highlight Toyota's mass production system, which revolutionized automotive manufacturing by drastically reducing costs and increasing output through standardized processes. In contrast, microfactories like Local Motors deploy flexible, small-scale production to rapidly prototype and customize vehicles, enhancing innovation and local responsiveness. These success stories demonstrate how mass production excels in economies of scale while microfactories thrive in adaptability and niche market responsiveness.

Future Trends in Manufacturing: Toward Hyper-local Production

Mass production has traditionally dominated manufacturing with large-scale centralized factories driving economies of scale, but future trends are shifting toward hyper-local production enabled by microfactories. Microfactories leverage advanced automation, 3D printing, and IoT technologies to enable flexible, decentralized manufacturing closer to end consumers, reducing lead times and transportation costs. This transition supports customized products, rapid innovation cycles, and sustainable practices, positioning microfactories as a key element in the evolving manufacturing landscape.

Related Important Terms

Distributed Microfactories

Distributed microfactories enable mass production with enhanced flexibility by decentralizing manufacturing processes across multiple small-scale facilities, reducing lead times and transportation costs. This approach supports localized customization and rapid response to market demand, contrasting with traditional mass production's reliance on large, centralized plants.

Agile Manufacturing Cells

Agile manufacturing cells within microfactories enable rapid customization and flexible production runs, contrasting with mass production's standardized, high-volume output. These cells integrate automated equipment and skilled workers to quickly adapt processes, reducing lead times and minimizing waste while maintaining quality in small batch manufacturing.

Just-In-Time Customization

Mass production emphasizes high-volume output with standardized products, often leading to excess inventory and inflexible customization options, whereas microfactories leverage Just-In-Time (JIT) manufacturing to deliver customized products rapidly by minimizing inventory and streamlining production processes. JIT customization in microfactories enhances responsiveness to market demand, reduces waste, and enables agile scaling of production based on real-time data.

Digital Twin-Based Production

Digital twin-based production enhances mass production by enabling real-time monitoring and simulation of entire manufacturing lines, improving efficiency and reducing downtime. In microfactories, digital twins offer granular control of localized processes, facilitating rapid customization and agile responses to demand fluctuations.

Batch-Size-One Manufacturing

Mass production emphasizes economies of scale by producing large quantities of identical products, whereas microfactories enable batch-size-one manufacturing, allowing customization and rapid response to market changes. Batch-size-one manufacturing leverages advanced automation and digital technologies to deliver personalized products efficiently without sacrificing cost-effectiveness.

On-Demand Fabrication

Mass production relies on standardized processes to produce large volumes of identical products, minimizing costs but limiting customization and responsiveness. Microfactories enable on-demand fabrication through flexible, localized manufacturing systems that reduce inventory waste and accelerate product delivery tailored to specific customer needs.

Hyperlocal Manufacturing

Hyperlocal manufacturing through microfactories enables localized production, reducing transportation costs and lead times compared to traditional mass production facilities. This shift enhances supply chain resilience and customization by situating production closer to end consumers while leveraging advanced automation and digital technologies.

Flexible Automation

Mass production relies on rigid automation systems designed for high-volume output but lacks adaptability to product variations, while microfactories employ flexible automation technologies such as modular robotics and AI-driven machinery to quickly reconfigure production lines for diverse, small-batch manufacturing. This flexibility enables microfactories to reduce lead times, minimize waste, and respond rapidly to market demands compared to traditional mass production facilities.

Scalable Production Networks

Mass production excels in delivering high volumes through standardized processes, optimizing cost-efficiency and speed in large-scale manufacturing. Microfactories enable scalable production networks by offering flexible, decentralized manufacturing units that adapt quickly to market demands and reduce logistical complexities.

Adaptive Assembly Lines

Adaptive assembly lines in mass production enhance efficiency by automating repetitive tasks at large scales, while microfactories leverage these lines for flexible, small-batch manufacturing tailored to specific demands. Integration of IoT and AI technologies in adaptive assembly lines enables real-time adjustments, minimizing downtime and optimizing resource utilization within both mass production and microfactory environments.

Mass Production vs Microfactory Infographic

industrydif.com

industrydif.com