Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and process standardization to enhance product quality and customer satisfaction. Predictive Quality leverages data analytics and machine learning models to anticipate defects and optimize manufacturing processes in real time. Integrating TQM with predictive quality techniques leads to more proactive quality control and reduced production costs.

Table of Comparison

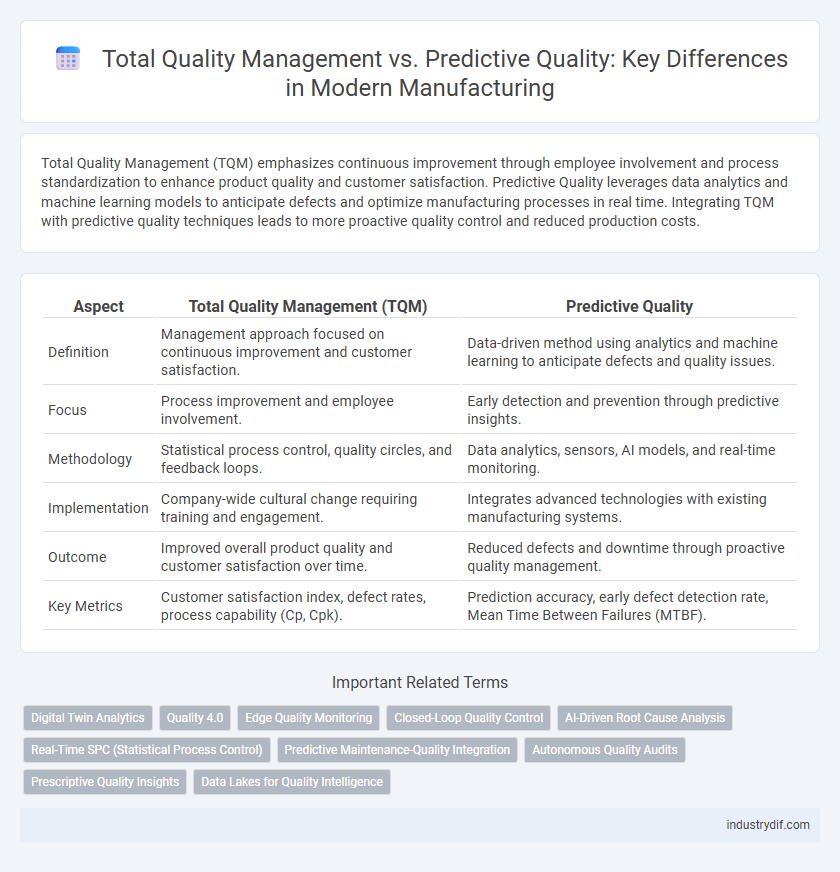

| Aspect | Total Quality Management (TQM) | Predictive Quality |

|---|---|---|

| Definition | Management approach focused on continuous improvement and customer satisfaction. | Data-driven method using analytics and machine learning to anticipate defects and quality issues. |

| Focus | Process improvement and employee involvement. | Early detection and prevention through predictive insights. |

| Methodology | Statistical process control, quality circles, and feedback loops. | Data analytics, sensors, AI models, and real-time monitoring. |

| Implementation | Company-wide cultural change requiring training and engagement. | Integrates advanced technologies with existing manufacturing systems. |

| Outcome | Improved overall product quality and customer satisfaction over time. | Reduced defects and downtime through proactive quality management. |

| Key Metrics | Customer satisfaction index, defect rates, process capability (Cp, Cpk). | Prediction accuracy, early defect detection rate, Mean Time Between Failures (MTBF). |

Understanding Total Quality Management in Manufacturing

Total Quality Management (TQM) in manufacturing emphasizes continuous improvement, customer satisfaction, and employee involvement to enhance product quality and operational efficiency. It integrates quality management principles into every stage of the production process, fostering a culture of proactive problem-solving and defect prevention. TQM's holistic approach contrasts with Predictive Quality, which relies heavily on data analytics and real-time monitoring to anticipate and mitigate quality issues before they occur.

Key Principles of Predictive Quality

Predictive Quality in manufacturing emphasizes data-driven decision-making and real-time analytics to anticipate defects before they occur, contrasting with Total Quality Management's focus on continuous improvement and employee involvement. Key principles include leveraging advanced sensors and machine learning algorithms to monitor production processes, enabling proactive adjustments and reducing waste. This approach enhances product consistency and operational efficiency by shifting quality control from reactive inspections to predictive maintenance and process optimization.

Core Differences: TQM vs Predictive Quality

Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction through proactive process control and team involvement, relying heavily on qualitative feedback and historical data analysis. Predictive Quality leverages advanced analytics, machine learning, and real-time sensor data to forecast defects and optimize production parameters before quality issues arise. The core difference lies in TQM's reactive, process-oriented approach versus Predictive Quality's proactive, data-driven methodology for minimizing defects and enhancing manufacturing efficiency.

Evolution of Quality Strategies in Manufacturing

Total Quality Management (TQM) established a foundation of continuous improvement and customer focus in manufacturing by systematically reducing defects through employee involvement and process standardization. Predictive Quality represents an evolution by leveraging data analytics, machine learning, and real-time monitoring to anticipate and prevent quality issues before they occur. This shift from reactive to proactive quality strategies enhances production efficiency, minimizes downtime, and supports smart manufacturing initiatives.

Data-Driven Approaches in Quality Management

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and standardized procedures, relying heavily on historical quality data to identify defects and improve processes. Predictive Quality leverages advanced data-driven approaches like machine learning and real-time analytics to anticipate and prevent defects before they occur, enhancing decision-making with predictive models. Integrating predictive analytics into quality management systems transforms traditional reactive quality control into proactive, data-centric strategies that optimize manufacturing performance and reduce costs.

Impact on Production Efficiency

Total Quality Management (TQM) enhances production efficiency by fostering continuous improvement and employee involvement, reducing defects, and minimizing waste throughout manufacturing processes. Predictive Quality leverages data analytics and machine learning to anticipate quality issues before they occur, enabling proactive adjustments that prevent downtime and improve throughput. Integrating Predictive Quality within TQM frameworks maximizes production efficiency by combining real-time insights with comprehensive quality culture, resulting in optimized resource utilization and consistent product standards.

Role of Technology in Quality Assurance

Total Quality Management (TQM) relies on systematic processes and continuous improvement frameworks to enhance product quality, leveraging technologies such as Statistical Process Control (SPC) and Enterprise Resource Planning (ERP) to monitor production consistency. Predictive Quality integrates advanced technologies like IoT sensors, machine learning algorithms, and real-time data analytics to anticipate defects and optimize quality outcomes before they occur. The role of technology in quality assurance transforms traditional reactive methods into proactive strategies, significantly reducing waste, downtime, and manufacturing costs.

Employee Involvement in TQM and Predictive Quality

Total Quality Management (TQM) emphasizes extensive employee involvement by fostering a culture where workers at all levels contribute to continuous improvement and quality enhancement. Predictive Quality leverages advanced data analytics and machine learning, allowing employees to proactively identify potential defects and optimize processes before issues arise. Integrating employee insights with predictive tools enhances manufacturing precision and reduces downtime, driving superior product quality and operational efficiency.

Implementation Challenges in Modern Manufacturing

Total Quality Management (TQM) faces implementation challenges in modern manufacturing due to its reliance on extensive employee training and cultural change, which can slow adoption in fast-paced environments. Predictive Quality leverages advanced data analytics and machine learning, but integrating IoT sensors and ensuring data accuracy pose significant technical hurdles. Both approaches require substantial investment in technology and process reengineering to align quality goals with dynamic production demands.

Choosing the Right Quality Approach for Your Facility

Total Quality Management (TQM) emphasizes continuous improvement and employee involvement to achieve long-term quality goals, making it ideal for facilities aiming to enhance overall processes and culture. Predictive Quality leverages data analytics and AI to foresee defects and optimize production in real time, offering a strategic advantage for high-tech manufacturing environments demanding rapid responsiveness. Selecting the right approach depends on facility size, technological capabilities, and goals for quality control integration and process innovation.

Related Important Terms

Digital Twin Analytics

Total Quality Management emphasizes process improvement through continuous feedback loops, while Predictive Quality leverages advanced Digital Twin Analytics to simulate manufacturing processes, predict defects, and optimize production in real time. Integrating Digital Twin technology enables manufacturers to reduce downtime, enhance product quality, and drive data-driven decision-making across the supply chain.

Quality 4.0

Total Quality Management (TQM) emphasizes continuous improvement and customer satisfaction through systematic processes, while Predictive Quality leverages advanced analytics and AI to foresee defects and optimize production in real time. Quality 4.0 integrates IoT, big data, and machine learning to transform traditional quality practices into proactive, data-driven strategies enhancing manufacturing efficiency and product excellence.

Edge Quality Monitoring

Total Quality Management (TQM) emphasizes comprehensive process control and continuous improvement throughout manufacturing, while Predictive Quality leverages real-time data analytics and machine learning to anticipate defects before they occur. Edge Quality Monitoring enhances Predictive Quality by deploying IoT sensors and AI at the production site, enabling immediate detection and correction of quality deviations to reduce downtime and improve yield.

Closed-Loop Quality Control

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and process standardization, while Predictive Quality utilizes data analytics and machine learning for proactive defect detection. Closed-Loop Quality Control integrates real-time feedback from production processes to enable immediate corrective actions, enhancing both TQM and Predictive Quality frameworks by minimizing defects and optimizing manufacturing efficiency.

AI-Driven Root Cause Analysis

AI-driven root cause analysis in Total Quality Management (TQM) enables real-time defect detection and process optimization by analyzing vast datasets to uncover hidden patterns, reducing human error and downtime. Predictive Quality extends this capability by leveraging machine learning algorithms to forecast potential quality issues before they occur, enhancing proactive decision-making and continuous improvement in manufacturing processes.

Real-Time SPC (Statistical Process Control)

Real-Time Statistical Process Control (SPC) within Total Quality Management (TQM) emphasizes continuous monitoring and control of manufacturing processes to ensure defect-free production and consistent product quality. Predictive Quality leverages real-time SPC data combined with advanced analytics and machine learning to forecast process deviations and proactively adjust parameters, reducing downtime and enhancing efficiency.

Predictive Maintenance-Quality Integration

Predictive Maintenance-Quality Integration enhances Total Quality Management by leveraging real-time data analytics and IoT sensors to anticipate equipment failures and maintain product quality standards consistently. This approach reduces downtime, minimizes defects, and drives continuous improvement by aligning maintenance schedules directly with production quality metrics.

Autonomous Quality Audits

Total Quality Management (TQM) emphasizes continuous process improvements through systematic audits, while Predictive Quality leverages data analytics and machine learning for autonomous quality audits, enabling real-time detection and correction of defects. Autonomous quality audits reduce human error and operational costs by automating inspection processes, driving higher efficiency and enhanced product reliability in manufacturing environments.

Prescriptive Quality Insights

Total Quality Management (TQM) emphasizes continuous improvement through employee involvement and process standardization, while Predictive Quality leverages data analytics and machine learning to forecast defects before they occur. Prescriptive Quality insights go further by recommending specific corrective actions based on predictive models, enabling manufacturers to optimize processes and prevent quality issues proactively.

Data Lakes for Quality Intelligence

Total Quality Management (TQM) emphasizes continuous improvement through systematic processes, while Predictive Quality leverages advanced data analytics within data lakes to proactively identify defects before they occur. Data lakes provide a centralized repository for vast manufacturing quality data, enabling quality intelligence systems to perform real-time predictive analysis and drive informed decision-making.

Total Quality Management vs Predictive Quality Infographic

industrydif.com

industrydif.com