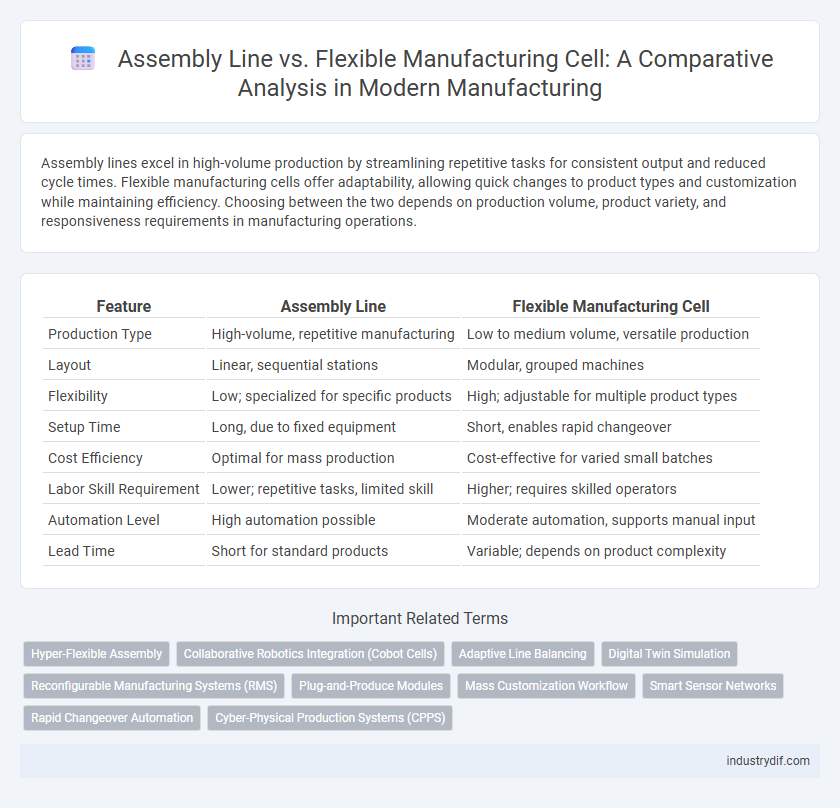

Assembly lines excel in high-volume production by streamlining repetitive tasks for consistent output and reduced cycle times. Flexible manufacturing cells offer adaptability, allowing quick changes to product types and customization while maintaining efficiency. Choosing between the two depends on production volume, product variety, and responsiveness requirements in manufacturing operations.

Table of Comparison

| Feature | Assembly Line | Flexible Manufacturing Cell |

|---|---|---|

| Production Type | High-volume, repetitive manufacturing | Low to medium volume, versatile production |

| Layout | Linear, sequential stations | Modular, grouped machines |

| Flexibility | Low; specialized for specific products | High; adjustable for multiple product types |

| Setup Time | Long, due to fixed equipment | Short, enables rapid changeover |

| Cost Efficiency | Optimal for mass production | Cost-effective for varied small batches |

| Labor Skill Requirement | Lower; repetitive tasks, limited skill | Higher; requires skilled operators |

| Automation Level | High automation possible | Moderate automation, supports manual input |

| Lead Time | Short for standard products | Variable; depends on product complexity |

Introduction to Manufacturing Systems

Assembly lines in manufacturing optimize high-volume production through sequential, specialized tasks that maximize efficiency but often lack adaptability. Flexible manufacturing cells consist of modular machines and robots designed to handle variable product types, enabling quick changeovers and customization. Integrating these systems enhances operational agility by balancing mass production with responsiveness to market demands.

Defining Assembly Line Production

Assembly line production is a manufacturing process where products move sequentially through a series of workstations, each performing a specific task to assemble the final product efficiently. This method emphasizes high volume, standardized output, and reduced cycle times by minimizing worker movement and task variation. Compared to flexible manufacturing cells, assembly lines prioritize speed and repetition over adaptability and customization.

Understanding Flexible Manufacturing Cells

Flexible manufacturing cells enhance production efficiency by integrating a group of computer-controlled machines capable of producing various parts without extensive retooling. Unlike traditional assembly lines that follow a fixed sequence, these cells adapt quickly to changes in product design and volume, reducing downtime and increasing customization capabilities. Implementing flexible manufacturing cells supports lean manufacturing principles by minimizing waste and optimizing resource utilization within diverse production environments.

Historical Evolution of Assembly Lines

Assembly lines revolutionized manufacturing in the early 20th century, pioneered by Henry Ford's introduction of mass production for the Model T automobile. This innovation drastically reduced assembly time by dividing tasks into specialized stations, enabling high-volume output and standardized products. Over decades, advancements in automation and robotics have transformed traditional assembly lines, while flexible manufacturing cells emerged to address the need for customization and adaptability in modern production environments.

Key Features of Flexible Manufacturing Cells

Flexible manufacturing cells optimize production by integrating multiple machines and robots to perform varied tasks within a compact area, enhancing adaptability and efficiency. Key features include programmable equipment for quick changeovers, real-time process monitoring, and automation systems that reduce labor costs while maintaining high precision. This flexibility supports small batch production and customization, contrasting with the rigid sequence and specialization of traditional assembly lines.

Efficiency and Throughput Comparison

Assembly lines offer high efficiency and consistent throughput by specializing tasks along a fixed sequence, minimizing worker movement and reducing cycle time per unit. Flexible manufacturing cells enhance efficiency through adaptability, allowing quick changeovers and handling of varied product types but may experience lower throughput compared to traditional assembly lines. Evaluating production needs and product complexity determines the optimal balance between assembly line stability and flexible cell responsiveness for maximizing overall manufacturing efficiency and throughput.

Flexibility and Customization Capabilities

Assembly lines excel in producing high volumes of standardized products with minimal variation, optimizing efficiency through repetitive tasks and fixed workflows. Flexible manufacturing cells offer superior adaptability by accommodating multiple product types and customization options within the same setup, enabling rapid changeovers and tailored production runs. The choice between the two depends on balancing the need for mass production efficiency against the demand for customization and agility in manufacturing processes.

Automation and Technology Integration

Assembly lines utilize fixed automation with specialized machinery designed for high-volume production, ensuring consistent output and minimal variability. Flexible manufacturing cells incorporate programmable robots and CNC machines, enabling rapid reconfiguration and customization for varied product runs. Integration of IoT sensors and advanced control systems in flexible cells enhances real-time monitoring, predictive maintenance, and adaptive process optimization.

Cost Implications and Investment Considerations

Assembly lines require significant upfront capital investment in specialized machinery and infrastructure, resulting in high fixed costs but lower variable costs per unit due to economies of scale. Flexible manufacturing cells involve moderate initial investment with higher adaptability, enabling cost savings in changeovers and customization but often incurring increased labor and tooling expenses. Evaluating cost implications depends on production volume, product variety, and scalability, where assembly lines favor high-volume, low-mix products and flexible cells suit low-volume, high-mix manufacturing environments.

Choosing the Right Approach for Your Operation

Selecting between an assembly line and a flexible manufacturing cell depends on product volume, variety, and customization needs. Assembly lines excel in high-volume, standardized production by optimizing speed and reducing per-unit costs, while flexible manufacturing cells offer adaptability for mixed-product runs and rapid changeovers. Prioritizing operational goals and product characteristics ensures the chosen approach maximizes efficiency and responsiveness in your manufacturing process.

Related Important Terms

Hyper-Flexible Assembly

Hyper-flexible assembly integrates the continuous flow efficiency of traditional assembly lines with the adaptability of flexible manufacturing cells, enabling rapid reconfiguration to accommodate product variations without significant downtime. This approach leverages modular workstations and advanced automation technologies to optimize production speed while maintaining high customization capabilities, crucial for industries requiring both volume and variety.

Collaborative Robotics Integration (Cobot Cells)

Collaborative robotics integration in assembly lines enhances productivity by enabling precise, repeatable tasks alongside human operators, while flexible manufacturing cells (cobot cells) offer dynamic reconfiguration and adaptability for varied production demands. Cobot cells reduce downtime and improve ergonomic safety through real-time human-robot interaction, making them ideal for small batch sizes and complex assembly processes.

Adaptive Line Balancing

Adaptive line balancing in assembly lines optimizes task allocation by dynamically adjusting workstations to minimize idle time and enhance throughput, whereas flexible manufacturing cells focus on versatile machinery capable of handling multiple product types with rapid reconfiguration. This adaptive approach in assembly lines enables manufacturers to respond efficiently to demand fluctuations and product variations, increasing productivity and reducing bottlenecks.

Digital Twin Simulation

Digital Twin Simulation enhances both Assembly Lines and Flexible Manufacturing Cells by providing real-time data analytics and predictive maintenance, optimizing production efficiency and reducing downtime. In Assembly Lines, it models linear workflows for steady output, while in Flexible Manufacturing Cells, it simulates adaptable configurations to accommodate varying product designs and batch sizes.

Reconfigurable Manufacturing Systems (RMS)

Reconfigurable Manufacturing Systems (RMS) combine the high-volume efficiency of assembly lines with the adaptability of flexible manufacturing cells, enabling rapid customization and scalability in production. RMS architectures facilitate quick reconfiguration of equipment and workflows, reducing downtime and enhancing responsiveness to market demands in manufacturing environments.

Plug-and-Produce Modules

Plug-and-produce modules in flexible manufacturing cells enable rapid reconfiguration and integration without extensive downtime, contrasting with traditional assembly lines that rely on fixed, sequential processes. This modular approach enhances adaptability, reduces lead times, and supports customized production in dynamic manufacturing environments.

Mass Customization Workflow

Assembly lines optimize mass production with standardized workflows, while flexible manufacturing cells enable mass customization by allowing rapid adjustments and varied product configurations. Integrating flexible cells within assembly lines enhances workflow adaptability, improving efficiency in meeting diverse customer demands.

Smart Sensor Networks

Smart sensor networks enhance assembly lines by enabling real-time monitoring and predictive maintenance, significantly reducing downtime and increasing throughput. In flexible manufacturing cells, these networks provide adaptive feedback for dynamic reconfiguration, improving customization and operational efficiency.

Rapid Changeover Automation

Rapid changeover automation in assembly lines significantly reduces downtime by streamlining tool and fixture swaps, enabling high-volume production efficiency. Flexible manufacturing cells leverage programmable robotics and modular equipment to adapt quickly to varied product types, enhancing responsiveness and minimizing setup times.

Cyber-Physical Production Systems (CPPS)

Cyber-Physical Production Systems (CPPS) enhance Assembly Lines through real-time monitoring and automation, boosting efficiency and reducing downtime by integrating physical processes with digital control. In contrast, Flexible Manufacturing Cells leverage CPPS to adapt swiftly to product variations, enabling dynamic reconfiguration and personalized production with minimal human intervention.

Assembly Line vs Flexible Manufacturing Cell Infographic

industrydif.com

industrydif.com