Total Productive Maintenance (TPM) emphasizes proactive and preventive strategies involving all employees to maximize equipment effectiveness and reduce downtime. Prescriptive Maintenance utilizes advanced data analytics and machine learning algorithms to predict specific maintenance actions, minimizing unexpected failures with precision. Combining TPM's holistic approach with Prescriptive Maintenance's data-driven insights enhances operational efficiency and extends asset lifespan in manufacturing environments.

Table of Comparison

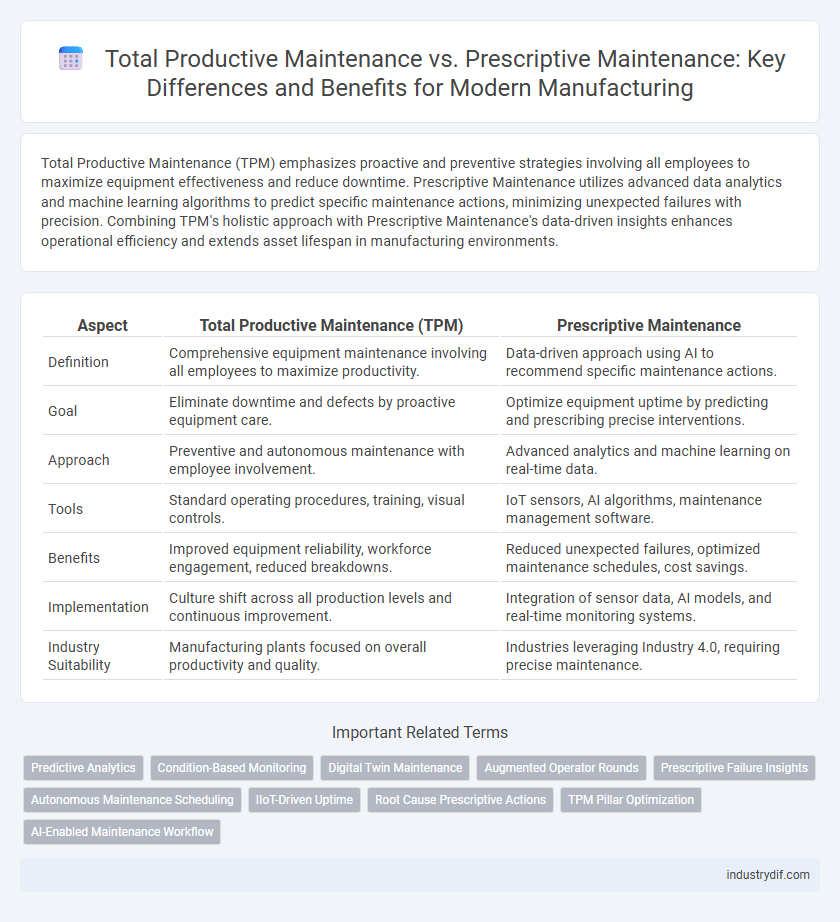

| Aspect | Total Productive Maintenance (TPM) | Prescriptive Maintenance |

|---|---|---|

| Definition | Comprehensive equipment maintenance involving all employees to maximize productivity. | Data-driven approach using AI to recommend specific maintenance actions. |

| Goal | Eliminate downtime and defects by proactive equipment care. | Optimize equipment uptime by predicting and prescribing precise interventions. |

| Approach | Preventive and autonomous maintenance with employee involvement. | Advanced analytics and machine learning on real-time data. |

| Tools | Standard operating procedures, training, visual controls. | IoT sensors, AI algorithms, maintenance management software. |

| Benefits | Improved equipment reliability, workforce engagement, reduced breakdowns. | Reduced unexpected failures, optimized maintenance schedules, cost savings. |

| Implementation | Culture shift across all production levels and continuous improvement. | Integration of sensor data, AI models, and real-time monitoring systems. |

| Industry Suitability | Manufacturing plants focused on overall productivity and quality. | Industries leveraging Industry 4.0, requiring precise maintenance. |

Introduction to Total Productive Maintenance (TPM) and Prescriptive Maintenance

Total Productive Maintenance (TPM) is a holistic approach aimed at maximizing equipment efficiency through proactive and preventive maintenance involving all employees. Prescriptive Maintenance leverages advanced analytics and AI algorithms to predict equipment failures and recommend specific maintenance actions. While TPM focuses on fostering a culture of continuous improvement and operator involvement, Prescriptive Maintenance emphasizes data-driven decision-making to optimize maintenance schedules and reduce downtime.

Core Principles of TPM

Total Productive Maintenance (TPM) centers on maximizing equipment effectiveness through proactive and preventive measures involving all employees, emphasizing autonomous maintenance, planned maintenance, focused improvement, and operator training. Prescriptive Maintenance uses advanced analytics and real-time data to predict and prescribe specific maintenance actions, aiming to reduce downtime and optimize asset performance. TPM's core principles foster a culture of continuous improvement and shared responsibility, contrasting with the technology-driven, data-centric approach of prescriptive maintenance.

Core Principles of Prescriptive Maintenance

Prescriptive maintenance is grounded in advanced data analytics and real-time monitoring to predict equipment failures and recommend specific corrective actions, optimizing asset performance and minimizing unplanned downtime. It leverages IoT sensors, machine learning algorithms, and historical data to provide actionable insights, enabling proactive decision-making. This approach contrasts with total productive maintenance by focusing on precise, data-driven prescriptions rather than broad preventive or corrective strategies.

Key Differences Between TPM and Prescriptive Maintenance

Total Productive Maintenance (TPM) emphasizes operator involvement in proactive and preventive maintenance activities to maximize equipment effectiveness and reduce downtime. Prescriptive Maintenance leverages advanced analytics, machine learning, and real-time sensor data to recommend specific maintenance actions before equipment failure occurs. TPM focuses on holistic plant-wide engagement and continuous improvement, while Prescriptive Maintenance prioritizes data-driven decision-making and predictive insights for optimized maintenance scheduling.

Role of Data Analytics in Maintenance Strategies

Data analytics plays a pivotal role in both Total Productive Maintenance (TPM) and Prescriptive Maintenance by enabling real-time monitoring and predictive insights to optimize equipment performance and minimize downtime. In TPM, data-driven indicators help empower operators to perform routine maintenance, enhancing overall equipment effectiveness (OEE) through early detection of anomalies. Prescriptive Maintenance leverages advanced analytics, AI, and machine learning models to recommend specific corrective actions, thereby improving decision-making and reducing unexpected failures in manufacturing processes.

Impact on Equipment Reliability and Uptime

Total Productive Maintenance (TPM) enhances equipment reliability by involving operators in routine maintenance tasks and emphasizing proactive prevention, leading to reduced breakdowns and increased uptime. Prescriptive Maintenance leverages advanced analytics and real-time data to predict failures and recommend specific actions, thus optimizing maintenance interventions and minimizing unplanned downtime. Implementing TPM fosters a culture of continuous improvement, while Prescriptive Maintenance ensures precise, data-driven decision-making for sustained equipment performance.

Workforce Involvement and Skill Requirements

Total Productive Maintenance (TPM) emphasizes extensive workforce involvement, requiring operators to engage in routine equipment inspections, cleaning, and minor repairs, which fosters cross-functional skill development and proactive maintenance culture. Prescriptive Maintenance relies more heavily on specialized technicians to interpret data analytics and AI-driven recommendations, demanding advanced training in digital tools and predictive algorithms. Integrating both approaches can optimize maintenance efficiency by balancing operator engagement with expert intervention, enhancing overall equipment reliability and workforce competency.

Implementation Challenges and Solutions

Total Productive Maintenance (TPM) implementation faces challenges such as cultural resistance, need for extensive employee training, and difficulty in maintaining cross-departmental collaboration. Prescriptive Maintenance requires integration of advanced IoT sensors and AI-driven analytics, which can be costly and demand high technical expertise. Solutions include phased training programs for TPM adoption, investment in scalable sensor technology for Prescriptive Maintenance, and leveraging cloud platforms to enhance data accessibility and decision-making efficiency.

Industry Use Cases and Applications

Total Productive Maintenance (TPM) enhances operational efficiency by emphasizing proactive equipment care and involving all employees in manufacturing plants to reduce unplanned downtime and improve asset availability. Prescriptive Maintenance leverages advanced data analytics and IoT sensors to predict failures and recommend precise maintenance actions, optimizing machine performance and reducing repair costs in smart factories. Industry applications of TPM are prevalent in automotive assembly lines for standardized maintenance routines, while prescriptive maintenance is widely adopted in aerospace manufacturing for real-time condition monitoring and failure prevention.

Deciding Between TPM and Prescriptive Maintenance

Deciding between Total Productive Maintenance (TPM) and Prescriptive Maintenance requires evaluating plant-specific factors such as equipment criticality, data availability, and maintenance resources. TPM emphasizes operator involvement and preventive strategies to maximize equipment effectiveness and reduce downtime, while Prescriptive Maintenance leverages advanced analytics and AI to predict and optimize maintenance actions based on real-time data. Manufacturing operations with mature data infrastructure and a focus on predictive insights benefit from Prescriptive Maintenance, whereas facilities emphasizing workforce engagement and holistic equipment care often prioritize TPM.

Related Important Terms

Predictive Analytics

Total Productive Maintenance (TPM) emphasizes proactive equipment care by involving all employees in routine upkeep to prevent breakdowns, while Prescriptive Maintenance leverages predictive analytics and AI algorithms to recommend specific actions based on real-time data and historical trends. Predictive analytics enhances Prescriptive Maintenance by analyzing sensor data, machine learning models, and operational patterns to optimize maintenance schedules, reduce downtime, and extend asset life in manufacturing environments.

Condition-Based Monitoring

Total Productive Maintenance (TPM) emphasizes operator involvement and proactive equipment care, whereas Prescriptive Maintenance uses advanced analytics driven by Condition-Based Monitoring (CBM) to predict and prevent failures. CBM technologies such as vibration analysis, thermal imaging, and ultrasonic testing enable real-time data collection, allowing Prescriptive Maintenance systems to optimize maintenance schedules and reduce unplanned downtime in manufacturing environments.

Digital Twin Maintenance

Total Productive Maintenance (TPM) emphasizes operator-driven equipment care to maximize overall equipment effectiveness (OEE), whereas Prescriptive Maintenance leverages advanced analytics and AI to recommend precise actions based on real-time data. Digital Twin Maintenance integrates with Prescriptive Maintenance by creating virtual replicas of manufacturing assets, enabling simulation-driven decision-making that enhances predictive accuracy and reduces unplanned downtime.

Augmented Operator Rounds

Total Productive Maintenance (TPM) emphasizes proactive operator rounds to detect equipment issues early through standardized checklists and visual inspections, enhancing overall equipment effectiveness (OEE). In contrast, Prescriptive Maintenance leverages AI-driven analytics during augmented operator rounds to provide real-time, data-driven action recommendations, reducing downtime and optimizing maintenance schedules.

Prescriptive Failure Insights

Prescriptive maintenance leverages advanced analytics and AI-driven algorithms to provide real-time failure predictions and actionable insights, optimizing equipment uptime and reducing unplanned downtime. This approach surpasses Total Productive Maintenance by delivering precise failure root cause analysis, enabling targeted interventions that enhance operational efficiency in manufacturing environments.

Autonomous Maintenance Scheduling

Total Productive Maintenance (TPM) emphasizes Autonomous Maintenance Scheduling by empowering operators to independently perform routine maintenance tasks, reducing downtime and enhancing equipment reliability. Prescriptive Maintenance leverages advanced analytics and real-time sensor data to predict failures and optimize maintenance schedules, enabling more precise and proactive interventions in manufacturing processes.

IIoT-Driven Uptime

Total Productive Maintenance (TPM) leverages IIoT sensors to monitor equipment health continuously, enabling operators to perform proactive maintenance and minimize downtime through real-time data insights. In contrast, Prescriptive Maintenance uses advanced analytics and machine learning models on IIoT data to recommend specific maintenance actions, optimizing uptime by predicting and preventing failures before they occur.

Root Cause Prescriptive Actions

Total Productive Maintenance (TPM) emphasizes operator-driven routine maintenance to prevent equipment failure, while Prescriptive Maintenance leverages real-time data analytics and AI to recommend root cause prescriptive actions for precise fault elimination. Root cause prescriptive actions in Prescriptive Maintenance optimize asset reliability by diagnosing underlying issues through sensor data, reducing downtime more effectively than TPM's proactive but generalized approach.

TPM Pillar Optimization

Total Productive Maintenance (TPM) emphasizes operator-driven upkeep and continuous improvement across equipment, optimizing the TPM pillars such as autonomous maintenance and planned maintenance to maximize asset reliability. Prescriptive Maintenance leverages real-time data analytics and AI to predict failures and prescribe precise interventions, enhancing TPM pillar optimization by integrating advanced condition monitoring and decision-making processes.

AI-Enabled Maintenance Workflow

AI-enabled maintenance workflow integrates Total Productive Maintenance (TPM) by enhancing equipment reliability through predictive analytics and real-time sensor data, enabling proactive operator involvement and continuous improvement. Prescriptive Maintenance utilizes advanced AI algorithms to recommend specific corrective actions based on historical data and machine learning, minimizing downtime and optimizing maintenance schedules for manufacturing assets.

Total Productive Maintenance vs Prescriptive Maintenance Infographic

industrydif.com

industrydif.com