Just-in-Time manufacturing emphasizes inventory reduction and efficiency by synchronizing production with demand, minimizing waste and lead times. Industry 5.0 integrates human creativity and advanced technologies such as AI and robotics to enhance personalized production, fostering collaboration between machines and workers. This evolution shifts the focus from mere efficiency to resilience, customization, and sustainability in modern manufacturing processes.

Table of Comparison

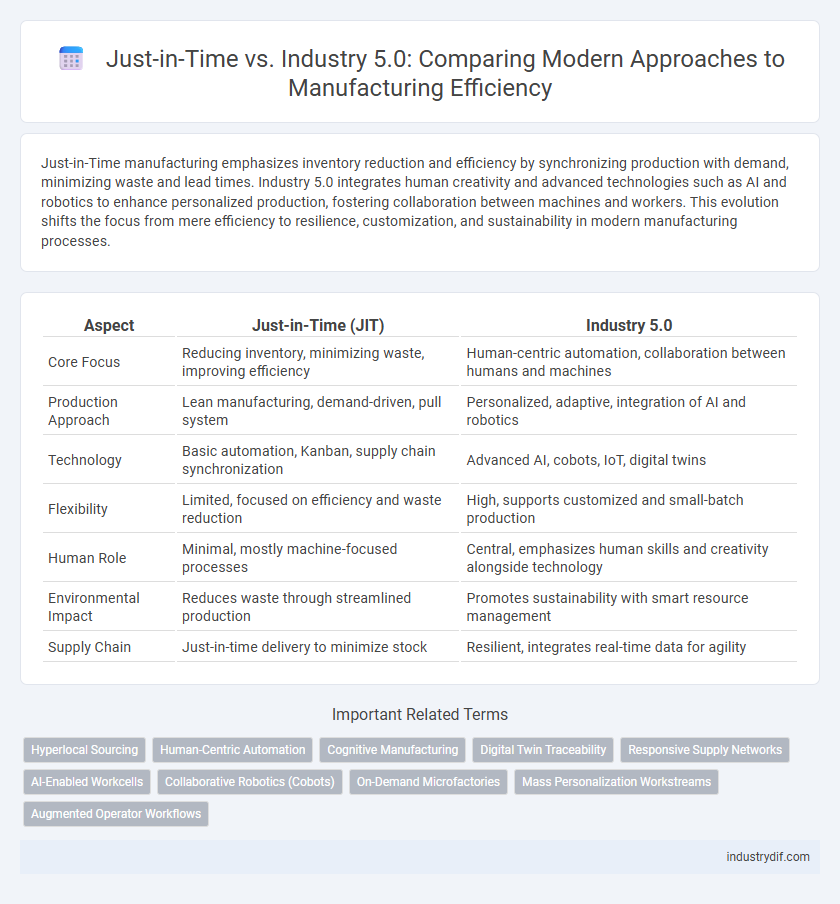

| Aspect | Just-in-Time (JIT) | Industry 5.0 |

|---|---|---|

| Core Focus | Reducing inventory, minimizing waste, improving efficiency | Human-centric automation, collaboration between humans and machines |

| Production Approach | Lean manufacturing, demand-driven, pull system | Personalized, adaptive, integration of AI and robotics |

| Technology | Basic automation, Kanban, supply chain synchronization | Advanced AI, cobots, IoT, digital twins |

| Flexibility | Limited, focused on efficiency and waste reduction | High, supports customized and small-batch production |

| Human Role | Minimal, mostly machine-focused processes | Central, emphasizes human skills and creativity alongside technology |

| Environmental Impact | Reduces waste through streamlined production | Promotes sustainability with smart resource management |

| Supply Chain | Just-in-time delivery to minimize stock | Resilient, integrates real-time data for agility |

Understanding Just-in-Time Manufacturing

Just-in-Time (JIT) Manufacturing minimizes inventory costs by producing goods only as they are needed, enhancing efficiency and reducing waste. This methodology relies on precise demand forecasting and streamlined supplier coordination to maintain seamless production flow. In contrast, Industry 5.0 integrates human creativity with advanced automation, emphasizing customization and sustainability beyond the efficiency-focused JIT approach.

The Emergence of Industry 5.0

Industry 5.0 represents the evolution beyond Just-in-Time manufacturing by integrating human creativity with advanced automation and artificial intelligence to enhance customization and sustainability. Unlike Just-in-Time's focus on efficiency and waste reduction, Industry 5.0 emphasizes collaboration between skilled workers and robots, leading to increased innovation and resilience in production processes. This shift enables manufacturers to respond faster to market demands while fostering a more sustainable and human-centered approach.

Key Principles of Just-in-Time Systems

Just-in-Time (JIT) systems prioritize minimizing inventory levels and reducing waste by producing goods only as they are needed, ensuring a seamless flow in the manufacturing process. Key principles include demand-driven production, continuous improvement (Kaizen), close supplier relationships, and elimination of overproduction and excess inventory. This lean approach contrasts with Industry 5.0's focus on human-centric integration, advanced automation, and personalized manufacturing solutions.

Core Concepts of Industry 5.0

Industry 5.0 emphasizes human-centric manufacturing by integrating advanced technologies like artificial intelligence, robotics, and IoT with skilled workers to enhance customization and sustainability. It moves beyond Just-in-Time's focus on efficiency and waste reduction by prioritizing collaboration between humans and machines to create resilient and flexible production systems. Core concepts include personalization, co-creation, and leveraging smart automation to improve both product quality and worker well-being in manufacturing processes.

Human-Centric Manufacturing in Industry 5.0

Industry 5.0 emphasizes human-centric manufacturing by integrating advanced robotics with human creativity, enhancing customization and worker well-being. This approach contrasts with Just-in-Time (JIT) systems, which primarily focus on efficiency and waste reduction through strict inventory control and timing. Human-centric Industry 5.0 fosters collaboration between humans and machines, promoting sustainable production and greater adaptability in manufacturing processes.

Efficiency and Waste Reduction in Just-in-Time

Just-in-Time (JIT) manufacturing significantly boosts efficiency by minimizing inventory levels and streamlining production schedules, ensuring materials arrive precisely when needed. This method drastically reduces waste through the elimination of excess stock and minimizes overproduction, contributing to leaner supply chains. Industry 5.0 builds on these principles by integrating human creativity with advanced automation, but JIT remains a foundational strategy for waste reduction and operational efficiency in modern manufacturing.

Integrating AI and Robotics in Industry 5.0

Industry 5.0 revolutionizes manufacturing by integrating AI and robotics to enhance precision, flexibility, and human-robot collaboration beyond the traditional Just-in-Time approach focused on inventory reduction. Intelligent systems in Industry 5.0 enable real-time decision-making, predictive maintenance, and customization, optimizing production efficiency while maintaining sustainability. This integration fosters a symbiotic relationship between humans and machines, driving innovation in smart factories and personalized manufacturing solutions.

Comparing Flexibility: Just-in-Time vs Industry 5.0

Just-in-Time manufacturing emphasizes minimizing inventory and streamlining production to reduce waste, enabling flexibility through lean processes and quick response to demand changes. Industry 5.0, on the other hand, enhances flexibility by integrating human creativity with advanced technologies like AI and collaborative robots, supporting personalized production and adaptive manufacturing environments. While Just-in-Time focuses on efficiency and cost reduction, Industry 5.0 prioritizes customization, resilience, and human-centric innovation for flexible production systems.

Challenges and Risks of Each Approach

Just-in-Time (JIT) manufacturing faces challenges such as supply chain disruptions, inventory shortages, and increased vulnerability to demand fluctuations, risking production delays and customer dissatisfaction. Industry 5.0 introduces human-machine collaboration risks, including cybersecurity threats and workforce skill gaps, while balancing customization demands with automation complexity. Both approaches require robust risk management to address operational uncertainties and maintain production resilience.

Future Trends in Manufacturing: Bridging Just-in-Time and Industry 5.0

Future trends in manufacturing emphasize integrating Just-in-Time (JIT) inventory strategies with Industry 5.0 principles to enhance customization and human-machine collaboration. Industry 5.0 advances the JIT model by incorporating AI-driven predictive analytics and cobot-assisted production lines, enabling real-time adaptability and minimizing waste. This synergy fosters resilient supply chains and sustainable manufacturing processes, aligning efficiency with personalized customer demands.

Related Important Terms

Hyperlocal Sourcing

Just-in-Time manufacturing minimizes inventory costs by receiving materials only as needed, but often relies on global supply chains prone to disruption; Industry 5.0, emphasizing hyperlocal sourcing, enhances resilience and sustainability by integrating advanced robotics with local suppliers to reduce lead times and carbon footprints. This shift towards hyperlocal sourcing aligns with Industry 5.0's focus on human-centric, environmentally conscious manufacturing processes, fostering stronger community economies and agile production systems.

Human-Centric Automation

Just-in-Time (JIT) manufacturing streamlines inventory by minimizing stock and reducing waste through precise production schedules, whereas Industry 5.0 emphasizes Human-Centric Automation by integrating smart machines with human creativity and decision-making to enhance flexibility and resilience in production processes. This synergy between advanced robotics and human expertise fosters personalized manufacturing, higher quality, and improved worker wellbeing.

Cognitive Manufacturing

Just-in-Time manufacturing optimizes inventory by reducing waste and streamlining production schedules, while Industry 5.0 integrates cognitive manufacturing technologies such as AI, IoT, and human-machine collaboration to enhance flexibility, customization, and decision-making in smart factories. Cognitive manufacturing leverages real-time data analytics and machine learning to predict maintenance needs and optimize workflow, surpassing traditional Just-in-Time approaches in efficiency and adaptability.

Digital Twin Traceability

Digital Twin technology enhances traceability in Industry 5.0 by creating real-time, virtual replicas of manufacturing processes, enabling precise monitoring and predictive maintenance. This contrasts with Just-in-Time manufacturing, which prioritizes inventory reduction but lacks the comprehensive data integration and adaptive capabilities provided by Digital Twins for dynamic decision-making.

Responsive Supply Networks

Just-in-Time manufacturing streamlines inventory by minimizing waste through precise demand forecasting, while Industry 5.0 emphasizes responsive supply networks that integrate human creativity with advanced technologies like AI and IoT for agile, adaptive production processes. Responsive supply networks in Industry 5.0 enhance real-time data sharing and collaboration across the value chain, enabling rapid adjustments to supply and demand fluctuations beyond the capabilities of traditional Just-in-Time systems.

AI-Enabled Workcells

Just-in-Time manufacturing emphasizes lean inventory and minimal waste by synchronizing production with demand, while Industry 5.0 integrates AI-enabled workcells to enhance human-machine collaboration, increasing customization and adaptability in production processes. AI-driven robotic systems within these workcells optimize efficiency and quality control, enabling real-time decision-making and reducing downtime in smart factories.

Collaborative Robotics (Cobots)

Just-in-Time manufacturing streamlines inventory by producing goods only as needed, reducing waste and costs, while Industry 5.0 integrates advanced collaborative robotics (cobots) to enhance human-robot interaction for greater precision and customization. Cobots equipped with AI and sensor technology improve flexibility and safety on production lines, driving efficiency and innovation in smart factories.

On-Demand Microfactories

On-demand microfactories enable Industry 5.0 by integrating advanced robotics and AI to achieve highly flexible, customized production compared to traditional Just-in-Time systems that prioritize inventory reduction and efficiency. These microfactories support localized, real-time manufacturing processes, enhancing responsiveness and sustainability by minimizing waste and adapting to dynamic market demands.

Mass Personalization Workstreams

Just-in-Time (JIT) manufacturing emphasizes reducing inventory and waste through precise scheduling, while Industry 5.0 integrates human creativity with advanced robotics to enable mass personalization workstreams. This shift promotes highly customized products at scale by combining real-time data analytics, collaborative robots, and flexible production systems.

Augmented Operator Workflows

Just-in-Time manufacturing emphasizes reducing inventory and waste through precise timing, while Industry 5.0 integrates human-centric augmented operator workflows with advanced AI and robotics to enhance decision-making and customization. Augmented operator workflows use real-time data and wearable technologies to empower workers, improving productivity and quality in smart factory environments.

Just-in-Time vs Industry 5.0 Infographic

industrydif.com

industrydif.com