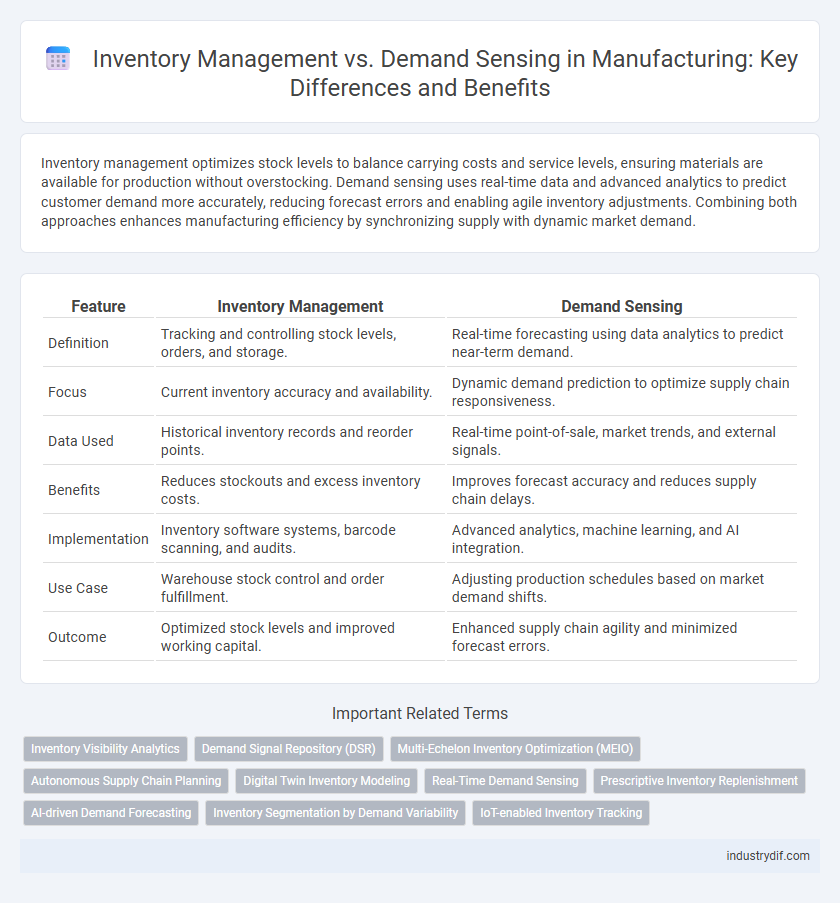

Inventory management optimizes stock levels to balance carrying costs and service levels, ensuring materials are available for production without overstocking. Demand sensing uses real-time data and advanced analytics to predict customer demand more accurately, reducing forecast errors and enabling agile inventory adjustments. Combining both approaches enhances manufacturing efficiency by synchronizing supply with dynamic market demand.

Table of Comparison

| Feature | Inventory Management | Demand Sensing |

|---|---|---|

| Definition | Tracking and controlling stock levels, orders, and storage. | Real-time forecasting using data analytics to predict near-term demand. |

| Focus | Current inventory accuracy and availability. | Dynamic demand prediction to optimize supply chain responsiveness. |

| Data Used | Historical inventory records and reorder points. | Real-time point-of-sale, market trends, and external signals. |

| Benefits | Reduces stockouts and excess inventory costs. | Improves forecast accuracy and reduces supply chain delays. |

| Implementation | Inventory software systems, barcode scanning, and audits. | Advanced analytics, machine learning, and AI integration. |

| Use Case | Warehouse stock control and order fulfillment. | Adjusting production schedules based on market demand shifts. |

| Outcome | Optimized stock levels and improved working capital. | Enhanced supply chain agility and minimized forecast errors. |

Overview of Inventory Management and Demand Sensing

Inventory management involves tracking and controlling raw materials, work-in-progress, and finished goods to optimize stock levels and reduce carrying costs. Demand sensing uses real-time data and advanced analytics to improve demand forecasting accuracy, enabling more responsive supply chain decisions. Combining these approaches enhances production planning and reduces stockouts and excess inventory in manufacturing environments.

Key Differences Between Inventory Management and Demand Sensing

Inventory management focuses on maintaining optimal stock levels to prevent overstocking or stockouts, using historical sales data and safety stock calculations. Demand sensing leverages real-time market signals, such as point-of-sale data and social media trends, to predict short-term demand fluctuations with higher accuracy. The key difference lies in inventory management's reliance on past data for long-term planning, whereas demand sensing uses immediate, granular data for agile, short-term demand forecasting.

Core Principles of Inventory Management

Inventory management centers on accurately tracking stock levels, optimizing reorder points, and minimizing holding costs to ensure product availability. It involves systematic forecasting based on historical sales data, lead times, and safety stock calculations to prevent stockouts or overstocking. Effective inventory management supports operational efficiency, cost reduction, and customer satisfaction within the manufacturing supply chain.

Understanding Demand Sensing in Manufacturing

Demand sensing in manufacturing leverages real-time data from multiple sources like sales, market trends, and supply chain inputs to improve forecast accuracy beyond traditional inventory management methods. By detecting subtle shifts in consumer behavior and external factors, demand sensing minimizes stockouts and excess inventory, optimizing production schedules. This approach enhances responsiveness to market fluctuations, reducing costs and improving customer satisfaction in manufacturing operations.

Impact of Inventory Accuracy on Supply Chain Performance

Inventory accuracy directly influences supply chain performance by reducing stockouts and overstocks, leading to optimal order fulfillment and lower carrying costs. Demand sensing leverages real-time data to enhance inventory accuracy, enabling more responsive replenishment and minimizing excess inventory. Improved inventory accuracy supports better forecasting, streamlines operations, and boosts overall supply chain efficiency in manufacturing environments.

Real-Time Data Utilization in Demand Sensing

Demand sensing leverages real-time data utilization to enhance inventory management by accurately capturing current market conditions, customer behaviors, and supply chain disruptions. This approach enables manufacturers to dynamically adjust production schedules and inventory levels, reducing excess stock and minimizing stockouts. Advanced analytics and machine learning algorithms process real-time inputs from sales, social media, and IoT devices, providing more precise demand forecasts than traditional inventory management methods.

Advantages of Integrating Demand Sensing with Inventory Management

Integrating demand sensing with inventory management enhances forecast accuracy by leveraging real-time data, reducing stockouts and excess inventory. This integration enables manufacturers to respond swiftly to market fluctuations, optimizing inventory levels and minimizing carrying costs. Improved synchronization between supply and demand drives operational efficiency and supports lean manufacturing principles.

Challenges in Implementing Demand Sensing Solutions

Implementing demand sensing solutions in manufacturing faces challenges such as integrating real-time data streams from diverse sources like ERP systems, IoT devices, and POS data, which requires robust IT infrastructure and data harmonization. Ensuring data accuracy and consistency is critical for effective demand forecasting, but discrepancies in data quality can lead to suboptimal inventory decisions and increased operational costs. Moreover, resistance to change within organizational culture and insufficient skilled personnel hinder the adoption and optimization of advanced demand sensing technologies.

Technology Trends Shaping Inventory Management and Demand Sensing

Advanced AI-driven analytics and machine learning algorithms are transforming inventory management by enabling real-time demand sensing, which enhances accuracy in forecasting and reduces stockouts. IoT sensors and cloud-based platforms provide seamless data integration from supply chains, facilitating automated replenishment and dynamic inventory adjustments. Blockchain technology ensures transparency and traceability, further optimizing inventory turnover and aligning supply with fluctuating customer demand patterns.

Future Outlook: Evolving Strategies for Inventory and Demand Alignment

Inventory management is increasingly integrating advanced demand sensing technologies that leverage real-time data analytics and AI to enhance forecast accuracy and responsiveness. Future strategies emphasize dynamic inventory adjustments based on predictive insights that reduce excess stock and minimize stockouts, improving supply chain agility. Manufacturers adopting these innovations can expect optimized inventory levels aligned closely with fluctuating market demand, resulting in cost savings and enhanced customer satisfaction.

Related Important Terms

Inventory Visibility Analytics

Inventory visibility analytics enhances manufacturing efficiency by providing real-time data on stock levels, enabling precise inventory management and reducing holding costs. Demand sensing integrates this analytics with predictive demand data to optimize supply chain responsiveness, preventing stockouts and overstock situations.

Demand Signal Repository (DSR)

Demand Signal Repository (DSR) centralizes real-time sales and point-of-sale data to enhance demand sensing accuracy, enabling manufacturers to adjust inventory levels promptly based on actual consumer demand patterns. Integrating DSR with inventory management systems reduces stockouts and overstock situations by providing granular visibility into market trends and customer purchasing behavior.

Multi-Echelon Inventory Optimization (MEIO)

Multi-Echelon Inventory Optimization (MEIO) enhances inventory management by considering multiple supply chain layers to balance stock levels, reduce costs, and improve service levels. Demand sensing integrates real-time market data to refine MEIO forecasts, enabling more accurate replenishment decisions and minimizing stockouts or excess inventory.

Autonomous Supply Chain Planning

Inventory management optimizes stock levels using historical data and predefined reorder points, while demand sensing leverages real-time data and AI algorithms to predict customer demand with greater accuracy. Autonomous supply chain planning integrates demand sensing to dynamically adjust inventory and production schedules, enhancing responsiveness and reducing excess stock in manufacturing operations.

Digital Twin Inventory Modeling

Digital Twin Inventory Modeling enhances inventory management by creating real-time, data-driven virtual replicas of physical stock, enabling precise demand sensing and adaptive replenishment strategies. This integration improves accuracy in forecasting, reduces stockouts, and optimizes supply chain responsiveness through dynamic simulation of inventory scenarios.

Real-Time Demand Sensing

Real-time demand sensing leverages advanced analytics and IoT data to provide immediate insights into customer demand patterns, enabling manufacturers to optimize inventory levels dynamically and reduce stockouts or overstock situations. Unlike traditional inventory management, which relies on historical data and fixed reorder points, real-time demand sensing enhances supply chain responsiveness and accuracy by continuously adjusting forecasts based on current market signals.

Prescriptive Inventory Replenishment

Prescriptive inventory replenishment leverages advanced data analytics and demand sensing to optimize stock levels, reducing both excess inventory and stockouts in manufacturing environments. By integrating real-time demand signals and predictive algorithms, manufacturers can synchronize production planning with actual market needs, enhancing supply chain responsiveness and operational efficiency.

AI-driven Demand Forecasting

AI-driven demand forecasting transforms inventory management by leveraging real-time data and machine learning algorithms to improve accuracy and responsiveness in predicting customer demand. Integrating demand sensing enhances supply chain efficiency by reducing stockouts and excess inventory, optimizing order fulfillment and production planning.

Inventory Segmentation by Demand Variability

Inventory segmentation by demand variability enables manufacturers to categorize stock based on fluctuating customer demand patterns, improving stock accuracy and reducing holding costs. Demand sensing enhances this process by utilizing real-time data analytics to predict short-term demand shifts, allowing for dynamic inventory adjustments that optimize service levels and minimize stockouts.

IoT-enabled Inventory Tracking

IoT-enabled inventory tracking enhances demand sensing by providing real-time, granular data on stock levels, reducing guesswork and improving forecast accuracy. This integration allows manufacturers to optimize inventory management, minimize stockouts, and align production schedules closely with actual demand fluctuations.

Inventory Management vs Demand Sensing Infographic

industrydif.com

industrydif.com